Functional mask fabric and preparation method thereof

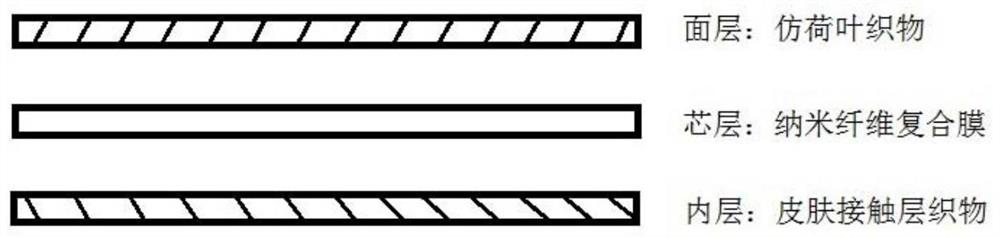

A functional mask technology, applied in textiles, clothing, protective clothing, etc., can solve the problems of inability to achieve recycling, inability to achieve long-lasting and effective filtration, etc., and achieve the effect of improving the quality and safety of protection and high barrier efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method of preparing a functional mask fabric, comprising the steps of:

[0026] Preparation of surface-layer imitation mushrooms: Using 50D / 48F of PLA filaments as latital weft yarns, the warp yarn density is 500 roots / 10cm, the weft yarn density is 320 roots / 10cm, the total coverage coefficient of the fabric is 54%, and the tissue structure is selected. The fabric blanket is made, washed 40 ° C for the fabric gray cloth, the water washing time is 20 min, the bath ratio is 1: 40, and the water washed after washing, the drying temperature is 50 ° C, the time is 30 min, and the development of the surface layer imitation mushroom fabric , Control gravity 50g / m 2 .

[0027] Preparation of core layer electrostatic spun nanofiber composite film: Electrostatic spinning technology using polypropylene solutions, 50 g / m 2 The surface of the hydrophilic ES hot air cotton having a thickness of 1.6 mm forms a layer of nanofiber microporous membrane. The spinning voltage is 5...

Embodiment 2

[0031] A method of preparing a functional mask fabric, comprising the steps of:

[0032] Preparation of surface-layer imitation shake fabric: Using 50D / 48F PLA filaments as latitude yarns, the warp yarn density is 520 roots / 10cm, the weft yarn density is 340 roots / 10cm, the total coverage coefficient of the fabric is 56%, and the tissue structure is selected. The fabric blanket is made of 35 ° C for 35 ° C, the water washing time is 25 min, and the bath ratio is 1:50, and the water washed, and the drying temperature is 60 ° C, the time is 15 min, and the surface layer imitation mushroom fabric is developed. , Control gravity 53g / m 2 .

[0033] Preparation of core layer electrostatic spun nanofiber composite film: Electrostatic spinning technology using polypropylene nitrile solution, gram weight is 42 g / m 2 The surface of the hydrophilic ES hot air cotton having a thickness of 1.7 mm forms a layer of nanofiber microporous membrane. The spinning voltage is 52kV, the spinn...

Embodiment 3

[0037] A method of preparing a functional mask fabric, comprising the steps of:

[0038] Preparation of the surface-layer imitation shadabad: Using 50D / 48F PLA filament as a weft yarn, the warp yarn density is 540 roots / 10cm, the weft yarn density is 360 roots / 10cm, the total coverage coefficient of the fabric is 58%, and the tissue structure is selected The fabric blanket is made, washed 45 ° C for the fabric gray cloth, the water washing time is 15 min, the bath ratio is 1:30, the water washed after washing, the drying temperature is 55 ° C, the time is 20 min, the time is 20 min, and the surface layer imitation lotus fabric is developed. , Control grade 57g / m 2 .

[0039] Preparation of core electrostatic spun nanofiber composite film: electrospinning technology using polypropylene solution, at 38 g / m 2 The surface of the hydrophilic ES hot air cotton having a thickness of 1.5 mm forms a layer of nanofiber microporous membrane. The spinning voltage is 48kV, the spinni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com