GMT plate and preparation method and application thereof

A sheet and composite material technology, applied in the field of GMT sheet and its preparation, can solve the problems of unfavorable lightweight development of GMT material, uniformity is not as uniform as wet process, high heating expansion height, etc., to achieve uniform bubble size, elasticity, The effect of distribution rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

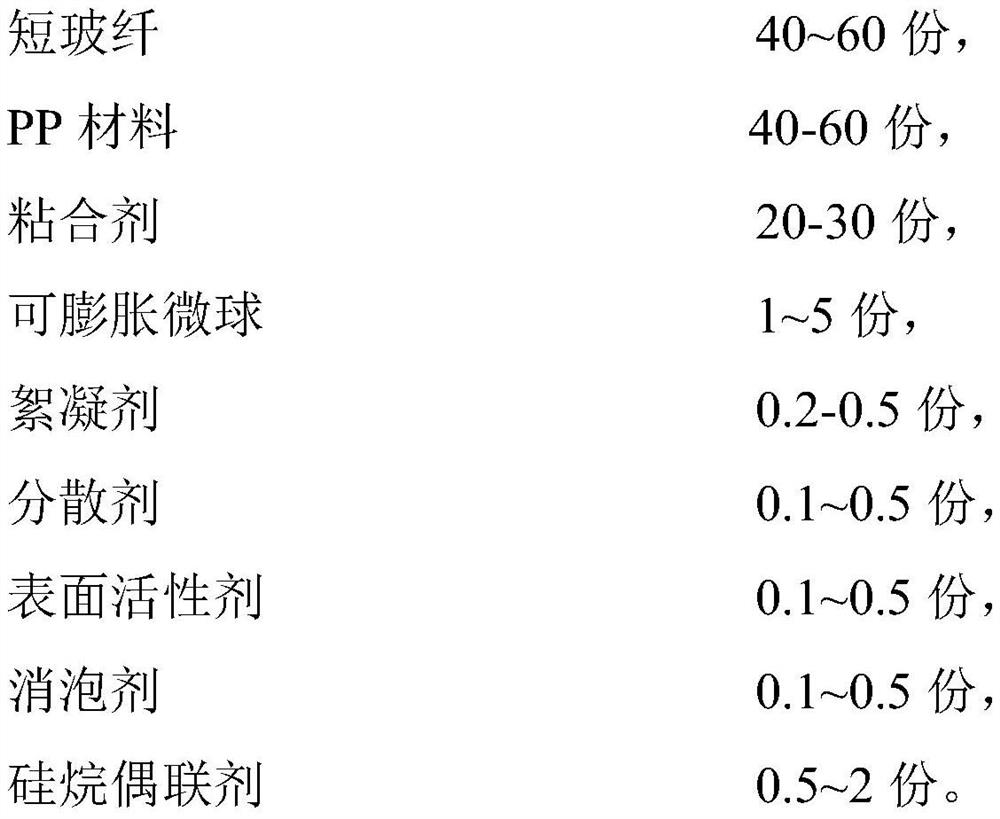

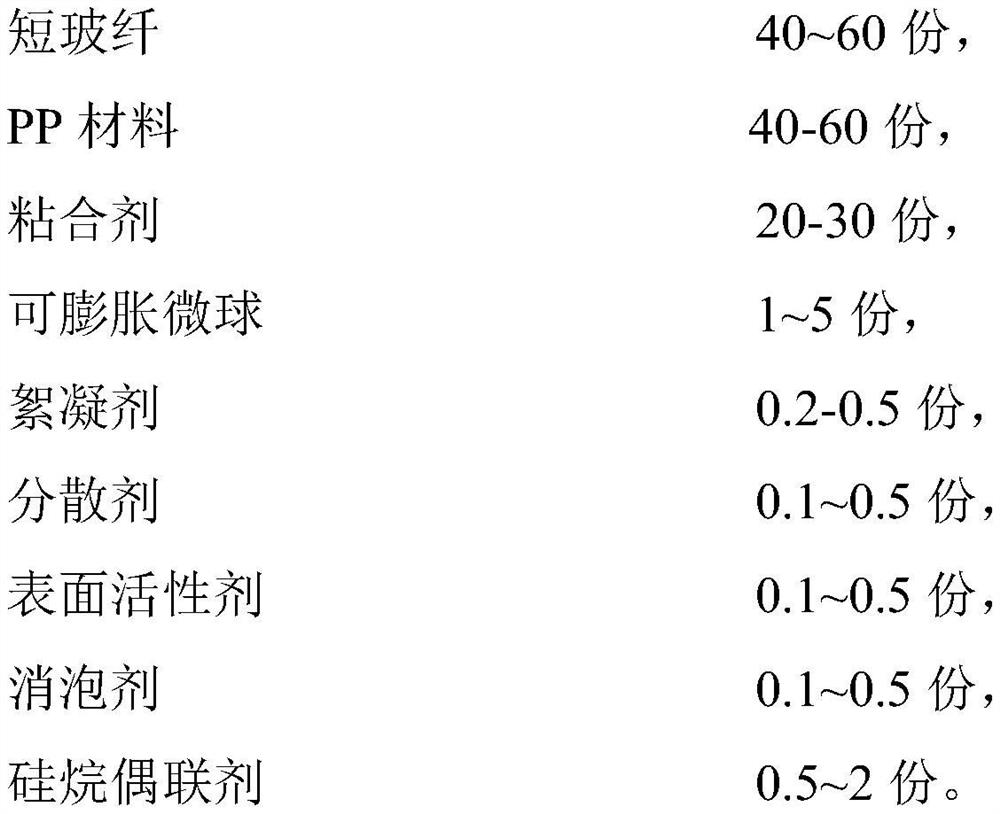

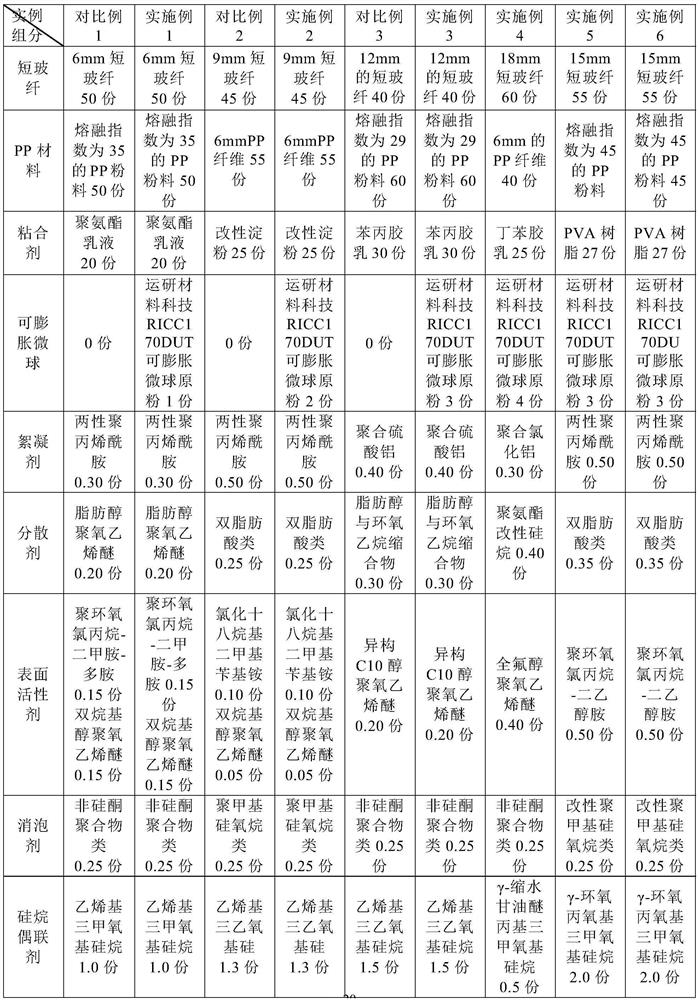

[0055] The GMT plate components of the present embodiment are shown in Table 1, and the preparation method may further comprise the steps:

[0056] (1) 50 parts by weight of short glass fibers with a length of 6mm and 1.0 parts by weight of vinyltrimethoxysilane coupling agent (Hangzhou Jessica Chemical Co., Ltd., KH-171) are placed at a high speed of 3000r / min. Fully mix in the mixer, the mixing time is 30min;

[0057] (2) Add 0.15 parts by weight of polyepichlorohydrin-dimethylamine-polyamine surfactant (Shaoxing Shangyu Simo Institute of Organic Chemistry, 002) and 0.10 parts by weight to the mixed solution in step (1) successively Fatty alcohol polyoxyethylene ether dispersant (Shenyang Sainio Chemical Co., Ltd., Pingpingjia 0-25), stirred in a high-speed mixer with a rotating speed of 3000r / min for 20min;

[0058] (3) Add 50 parts by weight of PP powder with a melt index of 35 and 0.10 parts by weight of fatty alcohol polyoxyethylene ether dispersant (Shenyang Sainio Che...

Embodiment 2

[0081] The GMT plate components of the present embodiment are shown in Table 1, and the preparation method may further comprise the steps:

[0082] (1) The length of 45 parts by weight is glass fiber of 9mm, vinyltriethoxysilane coupling agent (Hangzhou Jessica Chemical Co., Ltd., KH-151) of 1.3 parts by weight, at a high speed of 3200r / min Fully mix in the mixer, the mixing time is 32min;

[0083] (2) add the stearyl dimethyl benzyl ammonium chloride surfactant of 0.10 weight part successively in step (1), the double fatty acid dispersant of 0.15 weight part (Fuyang Hengli Special New Material Technology Co., Ltd. , HLT-200) was stirred in a high-speed mixer with a rotating speed of 3000r / min for 20min;

[0084] (3) Adding 55 parts by weight of PP fibers with a length of 6mm, 0.10 parts by weight of ethylene oxide condensate dispersant (Nantong Runfeng Petrochemical Co., Ltd., IW100), 0.05 parts by weight of bismuth Alkyl alcohol polyoxyethylene ether surfactant (Jinan Guoc...

Embodiment 3

[0107] The GMT plate components of the present embodiment are shown in Table 1, and the preparation method may further comprise the steps:

[0108] (1) Weigh 40 parts by weight of glass fiber with a length of 12mm and 1.5 parts by weight of vinyltriethoxysilane coupling agent (Hangzhou Jessica Chemical Co., Ltd., KH-151), at a speed of 4000r / min Fully mix in a high-speed mixer. The silane coupling agent is used as a surface modification treatment of glass fiber to increase its hydrophilicity, which is beneficial to the subsequent mixing and molding with PP materials. The mixing time is 35 minutes;

[0109] (2) Add 0.10 parts by weight of isomeric C10 alcohol polyoxyethylene ether (Foshan Jinjia New Material Technology Co., Ltd., 1005) surfactant, 0.20 parts by weight of fatty alcohol and ethylene oxide successively in step (1) Condensate (Nantong Runfeng Petrochemical Co., Ltd., IW100) dispersant was stirred in a high-speed mixer with a rotating speed of 4000r / min for 22min; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com