Preparation method for synthesizing inorganic perovskite nanocrystals by non-injection one-step method

A technology of inorganic calcium and nanocrystals, applied in inorganic chemistry, nanotechnology, chemical instruments and methods, etc., can solve the problems of difficulty in the formation process of nanocrystals, and achieve the advantages of mass production, easy storage and transportation, and high quantum efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

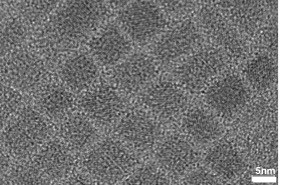

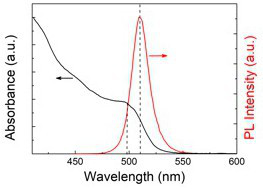

[0030] (1) Add 0.0525g cesium bromide, 0.0925g PbBr 2 , 315μL oleic acid, 315μL oleylamine, 5ml 1, 4 dioxane, 75μL deionized water mixed, continuous ultrasound or stirring at room temperature, can prepare CsPbBr 3 Colloidal solution of nanoblocks;

[0031] (2) CsPbBr 3 Colloidal solution of nanoblocks CsPbBr can be obtained after the colloidal solution is centrifuged at 10,000 r / min for 8 min, the supernatant is discarded, and dried in a vacuum oven at 50°C for 7 hours. 3 Nanoblock powder.

Embodiment 2

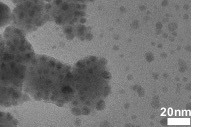

[0033] Using the same process as in Example 1, the difference is that the amount of deionized water in Example 1 is changed to 150 μL, and other conditions are kept the same, and the coating structure CsPbBr can be obtained 3 Nanocrystalline.

Embodiment 3

[0035] (1) Mix 0.047g cesium iodide, 0.083g PbI 2 , 250μL oleic acid, 250μL oleylamine, 4ml 1, 4 dioxane, 60μL deionized water mixed, 70 ℃ continuous ultrasound or stirring, you can prepare CsPbI 3 Colloidal solution of nanoblocks;

[0036] (2) CsPbI 3 Colloidal solution of nanoblocks CsPbI can be obtained after the colloidal solution is centrifuged at 10000 r / min for 8 min, the supernatant is discarded, and dried in a vacuum oven at 50 °C for 7 hours. 3 Nanoblock powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com