Quadruple shape memory hydrogel and preparation method thereof

A hydrogel and memory technology, applied in the field of quadruple shape memory hydrogel and its preparation, quadruple shape memory chitosan hydrogel and its preparation, can solve the problems of lack of industrial application prospects, insufficient mechanical properties, response Long time and other problems, to achieve the effect of fast response time, fast deformation recovery time, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

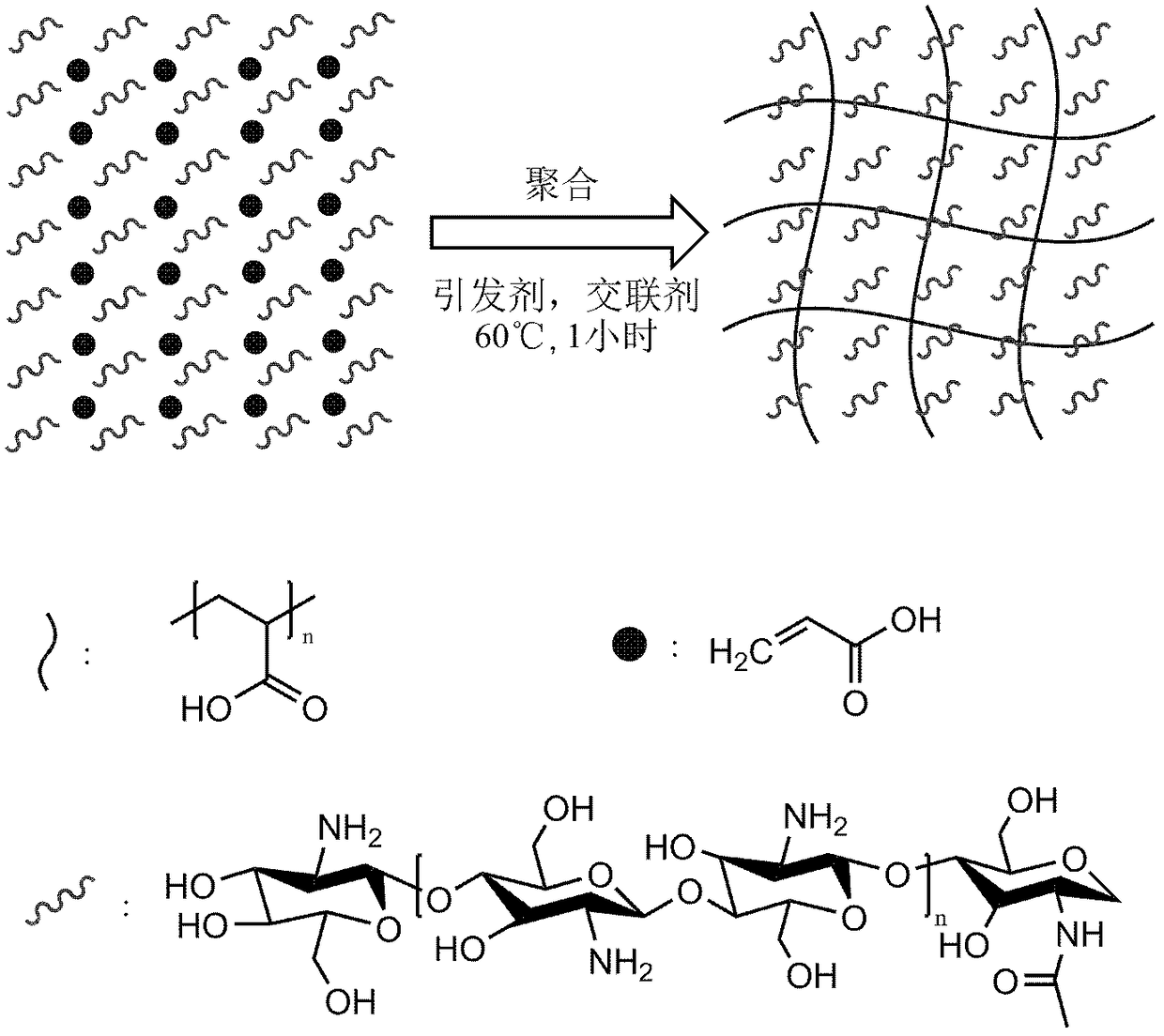

[0066] In this example, a quadruple shape memory hydrogel was prepared according to the following steps:

[0067] (1) Dissolve 2 parts of chitosan in 100 parts of acetic acid solution with a mass fraction of 1%, and stir for at least 12 hours to obtain a chitosan mixed solution.

[0068] (2) Take 5 parts of deionized water, add 5 parts of acrylic acid, 0.8 parts of ammonium persulfate, 0.02 parts of N,N'-methylenebisacrylamide, and 15 parts of chitosan obtained in step (1) under stirring conditions. Mix the sugar solution and continue to stir and mix for half a minute to obtain a uniform suspension.

[0069] (3) Pour the suspension obtained in step (2) into a petri dish and seal it, then put the petri dish into a desiccator at 60° C., and react for 1 hour to obtain a quadruple shape memory hydrogel.

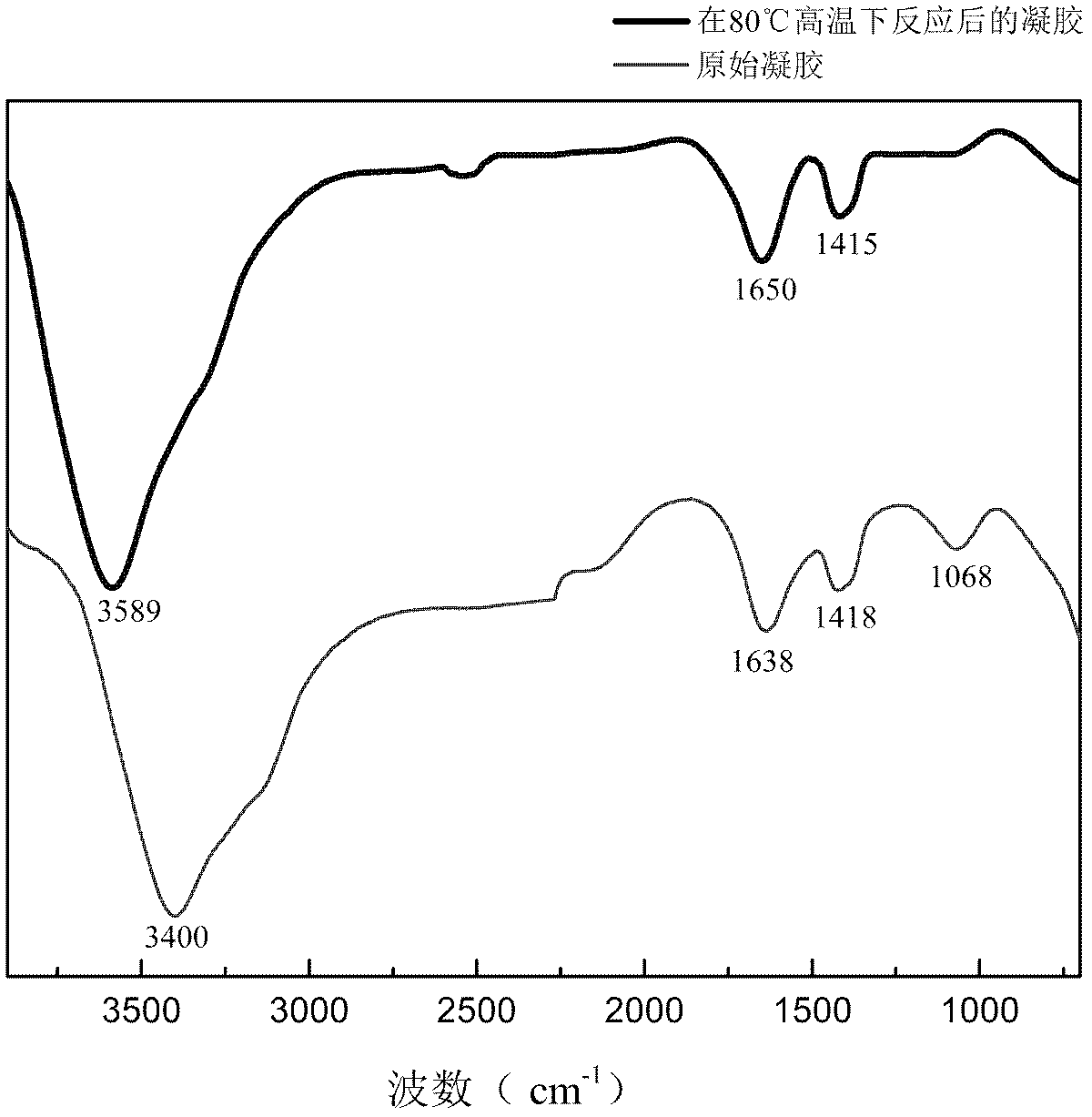

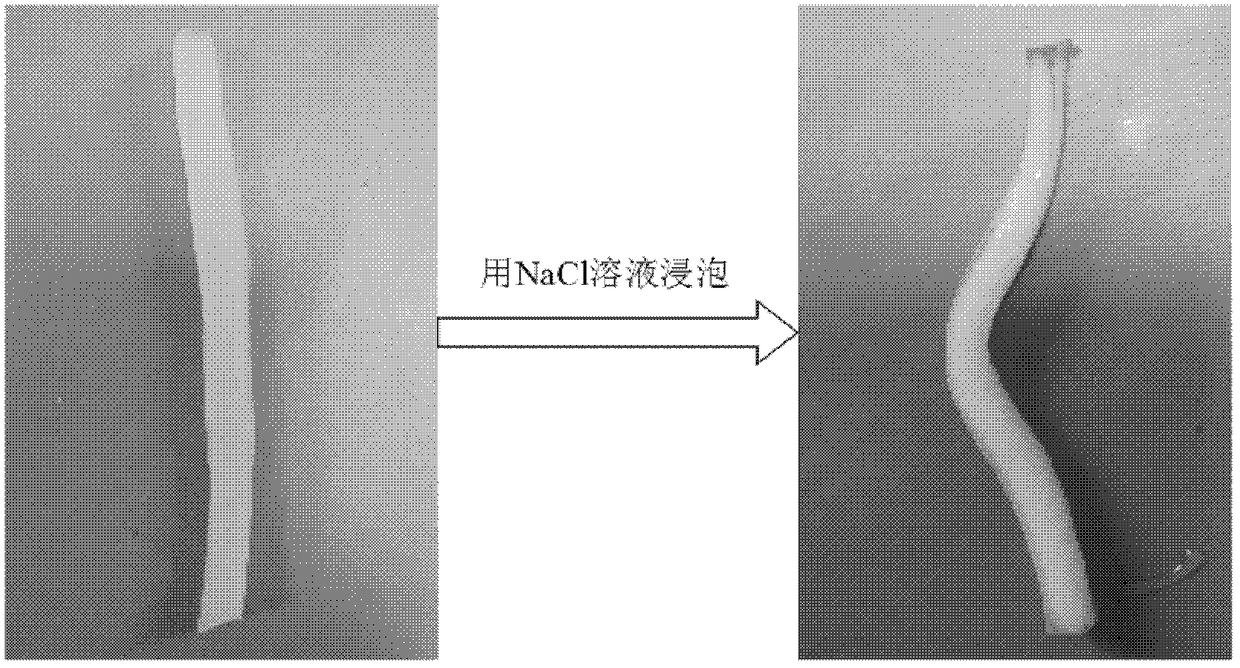

[0070] It has been determined that the hydrogel has a quadruple shape memory function, and in 3mol / L FeCl 3 In the solution, the maximum deformation rate can reach 100%, and th...

Embodiment 2

[0072] In this example, a quadruple shape memory hydrogel was prepared according to the following steps:

[0073] (1) Dissolve 2 parts of chitosan in 100 parts of acetic acid solution with a mass fraction of 1%, and stir for at least 12 hours to obtain a chitosan mixed solution.

[0074] (2) Take 5 parts of deionized water, add 5 parts of acrylic acid, 0.4 parts of ammonium persulfate, 0.02 parts of N,N'-methylenebisacrylamide, and 15 parts of chitosan obtained in step (1) under stirring conditions. Mix the sugar solution and continue to stir and mix for half a minute to obtain a uniform suspension.

[0075] (3) Pour the suspension obtained in step (2) into a petri dish and seal it, then put the petri dish into a desiccator at 60° C., and react for 1 hour to obtain a quadruple shape memory hydrogel.

[0076] It has been determined that the hydrogel has a quadruple shape memory function, and in 3mol / L FeCl 3 In the solution, the maximum deformation rate can reach 100%, and th...

Embodiment 3

[0078] In this example, a quadruple shape memory hydrogel was prepared according to the following steps:

[0079] (1) Dissolve 2 parts of chitosan in 100 parts of acetic acid solution with a mass fraction of 1%, and stir for at least 12 hours to obtain a chitosan mixed solution.

[0080] (2) Take 5 parts of deionized water, add 5 parts of acrylic acid, 0.4 parts of ammonium persulfate, 0.01 parts of N,N'-methylenebisacrylamide, and 15 parts of chitosan obtained in step (1) under stirring conditions. Mix the sugar solution and continue to stir and mix for half a minute to obtain a uniform suspension.

[0081] (3) Pour the suspension obtained in step (2) into a petri dish and seal it, then put the petri dish into a desiccator at 60° C., and react for 1 hour to obtain a quadruple shape memory hydrogel.

[0082] It has been determined that the hydrogel has a quadruple shape memory function, and in 3mol / L FeCl 3 In the solution, the maximum deformation rate can reach 100%, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com