Preparation method of multi-dimensional carbon material composite reinforced copper-based material

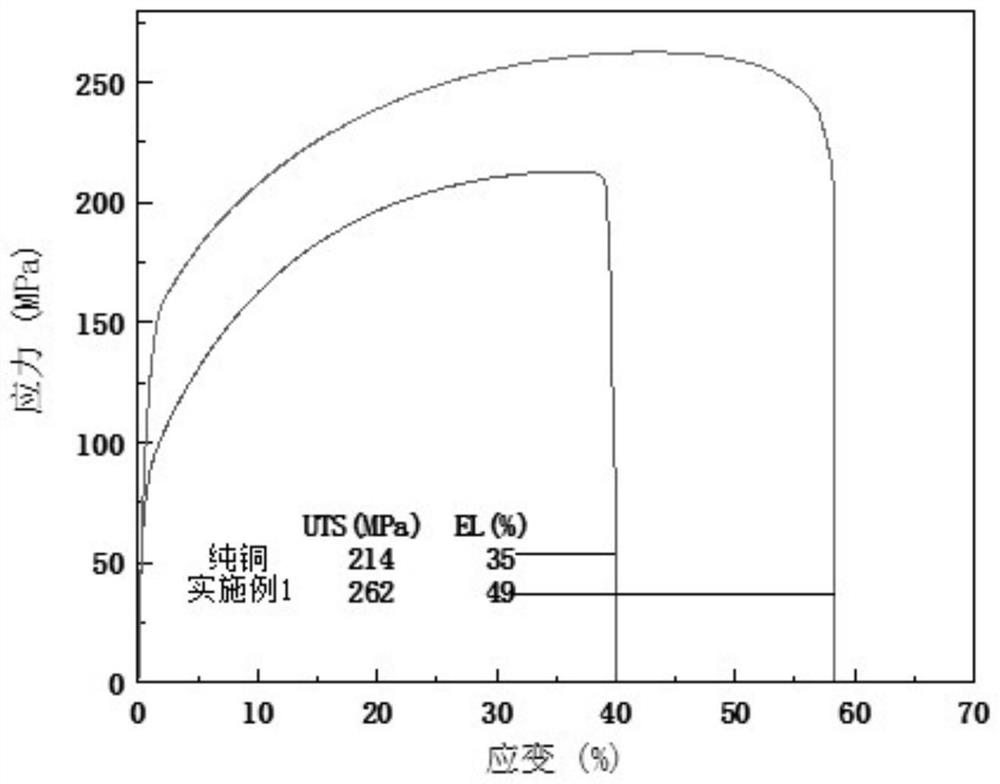

A composite reinforcement, carbon material technology, applied in the fields of nanotechnology, carbon compounds, chemical instruments and methods for materials and surface science, can solve the problems of strength enhancement elongation and electrical conductivity of copper matrix composites, which are difficult to achieve, Achieve the effect of good bonding strength, increased strength and elongation, and increased electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

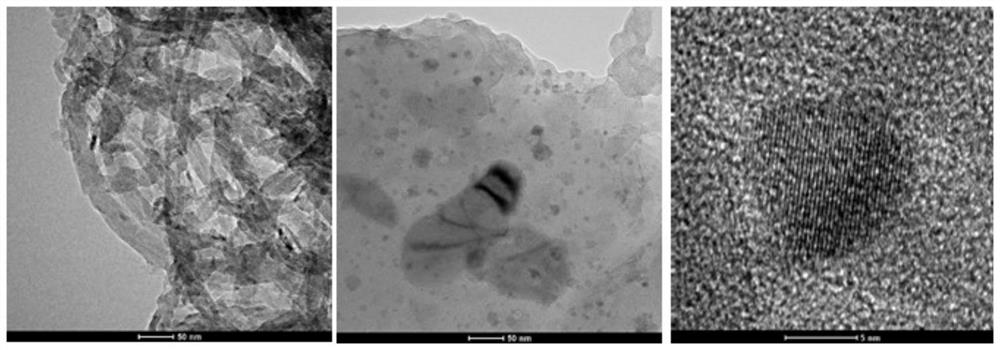

[0032] A method for preparing a multi-dimensional carbon material composite reinforced copper-based material, the specific steps are:

[0033] (1) Acid cracking: 500mg of nitrogen-doped carbon nanotubes and 250mL of concentrated nitric acid with a mass fraction of 68% were evenly mixed in a 1L three-necked round-bottomed flask, heated to 140°C and stirred for reflux for 48h;

[0034] (2) Alkali neutralization: the reflux liquid of step (1) is neutralized to neutrality in an ice bath with sodium hydroxide;

[0035] (3) Dialysis: Dialyze the neutralized dispersion in step (2) with a 500 Da dialysis bag in ultrapure water for 5 days;

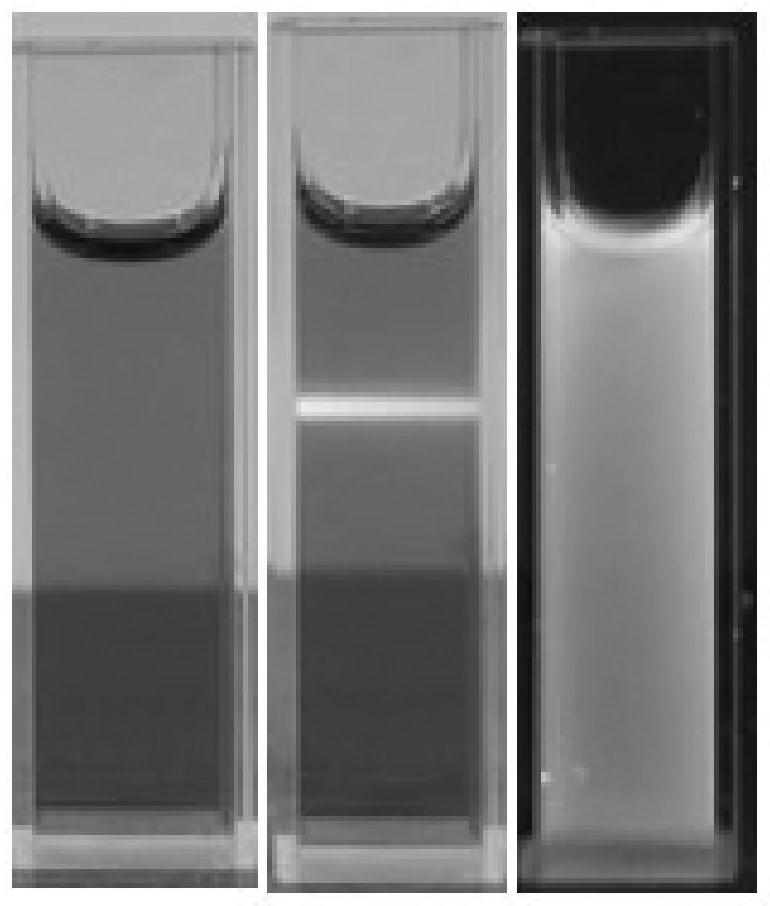

[0036] (4) Drying: The dispersion in the dialysis bag in step (3) was rotary evaporated at 60°C to a volume of about 50mL, and then freeze-dried to obtain nitrogen-doped carbon nanotube-graphene-graphene quantum dot powder. The rotary evaporation process continued Vacuumize to improve the efficiency of rotary evaporation;

[0037] (5) Composite p...

Embodiment 2

[0043] A method for preparing a multi-dimensional carbon material composite reinforced copper-based material, the specific steps are:

[0044] (1) Acid cracking: 250mg of graphitized carbon nanotubes and 250mL of concentrated nitric acid with a mass fraction of 68% were uniformly mixed in a 1L three-necked round-bottomed flask, heated to 140°C and stirred for reflux for 48h;

[0045] (2) Alkali neutralization: the reflux liquid of step (1) is neutralized to neutrality in a water bath with potassium hydroxide;

[0046] (3) Dialysis: Dialyze the neutralized dispersion in step (2) in ultrapure water for 4 days with a 1000 Da dialysis bag;

[0047] (4) Drying: Rotate the dispersion in the dialysis bag in step (3) at 70°C to a volume of about 50mL, freeze-dry to obtain graphitized carbon nanotube-graphene-graphene quantum dot powder, and continue vacuuming during the rotary evaporation process , improve the efficiency of rotary evaporation;

[0048] (5) Preparation of composite p...

Embodiment 3

[0052] A method for preparing a multi-dimensional carbon material composite reinforced copper-based material, the specific steps are:

[0053] (1) Acid cracking: 1000mg of industrialized carbon nanotubes and 250mL of concentrated nitric acid with a mass fraction of 68% were evenly mixed in a 1L three-neck round bottom flask, heated to 100°C and stirred for reflux for 96h;

[0054] (2) Alkali neutralization: the reflux solution of step (1) is neutralized to neutrality in an ice bath with a potassium hydroxide solution of concentration 5mol / L;

[0055] (3) Dialysis: Dialyze the neutralized dispersion in step (2) in ultrapure water for 6 days with a 3500 Da dialysis bag;

[0056] (4) Drying: Rotate the dispersion in the dialysis bag in step (3) at 80°C to about 50mL, freeze-dry to obtain industrialized carbon nanotube-graphene-graphene quantum dot powder, and continue vacuuming during the rotary evaporation process to improve Evaporation efficiency;

[0057] (5) Composite powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com