Modified epoxy polyurethane sealant and preparation method thereof

A technology of epoxy polyurethane and sealant, which is applied in the field of sealant, and can solve problems such as rapid failure, low temperature resistance, and poor insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

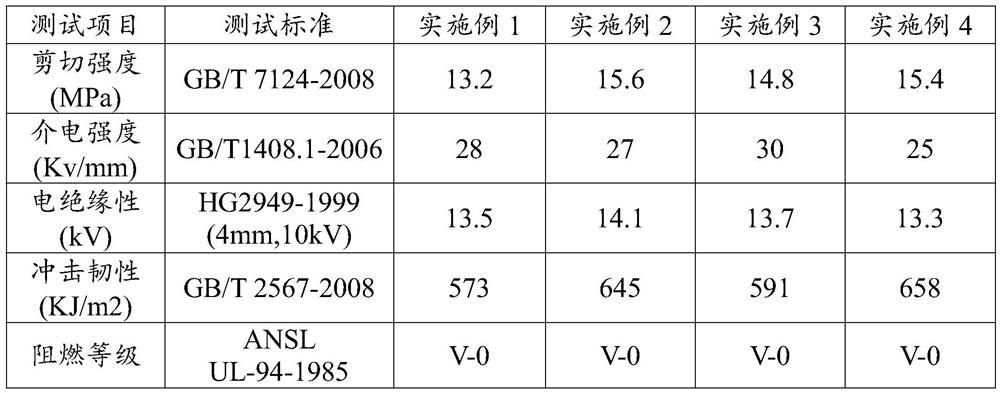

Examples

Embodiment 1

[0030] A modified epoxy polyurethane sealant, comprising the following raw materials in parts by mass: 10 parts of bisphenol A epoxy resin, 10 parts of vinyl ester resin, 0.1 part of silicon dioxide, 0.1 part of aluminum oxide, and 0.1 part of graphene oxide 0.01 part of octadecylamine, 5 parts of silane coupling agent, 10 parts of propylene oxide, 30 parts of dicyclohexylmethane diisocyanate, 30 parts of polyether triol, 1 part of dibutyltin dilaurate, polynitrogen 1 part of propidine crosslinking agent, 1 part of diethyltoluenediamine, 2 parts of curing agent, 20 parts of solvent;

[0031] The epoxy equivalent of the bisphenol A type epoxy resin is 180g / mol; the vinyl ester resin is vinyl ester resin 411; the curing agent is polyetheramine and polythiol composite curing agent, polyether The mass ratio of amine and polythiol is polyetheramine:polythiol=9:1; the solvent is acetone;

[0032] The preparation method of described modified epoxy polyurethane sealant comprises the ...

Embodiment 2

[0041] A modified epoxy polyurethane sealant, comprising the following raw materials in parts by mass: 20 parts of bisphenol A epoxy resin, 20 parts of vinyl ester resin, 0.5 part of silicon dioxide, 0.5 part of aluminum trioxide, 0.5 part of graphene oxide 0.2 parts of octadecylamine, 10 parts of silane coupling agent, 30 parts of propylene oxide, 50 parts of dicyclohexylmethane diisocyanate, 60 parts of polyether triol, 3 parts of dibutyltin dilaurate, polynitrogen 5 parts of propidine crosslinking agent, 5 parts of diethyltoluenediamine, 8 parts of curing agent, 30 parts of solvent;

[0042] The epoxy equivalent of the bisphenol A type epoxy resin is 200g / mol; the vinyl ester resin is vinyl ester resin 806; the curing agent is polyetheramine and polythiol composite curing agent, polyether The mass ratio of amine and polythiol is polyetheramine:polythiol=9:1; the solvent is dehydrated alcohol;

[0043] The preparation method of described modified epoxy polyurethane sealant ...

Embodiment 3

[0052] A modified epoxy polyurethane sealant, comprising the following raw materials in parts by mass: 15 parts of bisphenol A epoxy resin, 15 parts of vinyl ester resin, 0.3 part of silicon dioxide, 0.3 part of aluminum oxide, and 0.3 part of graphene oxide Parts, 0.1 parts of octadecylamine, 7 parts of silane coupling agent, 20 parts of propylene oxide, 40 parts of dicyclohexylmethane diisocyanate, 45 parts of polyether triol, 2 parts of dibutyltin dilaurate, polynitrogen 3 parts of propidine crosslinking agent, 3 parts of diethyltoluenediamine, 5 parts of curing agent, 25 parts of solvent;

[0053] The epoxy equivalent of the bisphenol A epoxy resin is 190g / mol; the vinyl ester resin is vinyl ester resin 430; the curing agent is polyetheramine and polythiol compound curing agent, polyether The mass ratio of amine and polythiol is polyetheramine:polythiol=9:1; the solvent is toluene;

[0054] The preparation method of described modified epoxy polyurethane sealant comprises ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com