Flame-retardant EPDM foaming thermal insulation material and preparation method thereof

A technology of thermal insulation material and flame retardancy, applied in the field of EPDM foam thermal insulation material and its preparation, can solve the problems of reducing the mechanical properties of elastomers, high toxicity and environmental pollution, poor processing stability, etc., and achieves improved mechanical strength, flame retardant The effect of good smoke suppression performance and comprehensive performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a flame-retardant EPDM foam insulation material and a preparation method thereof, which have good flame-retardant performance and high mechanical strength.

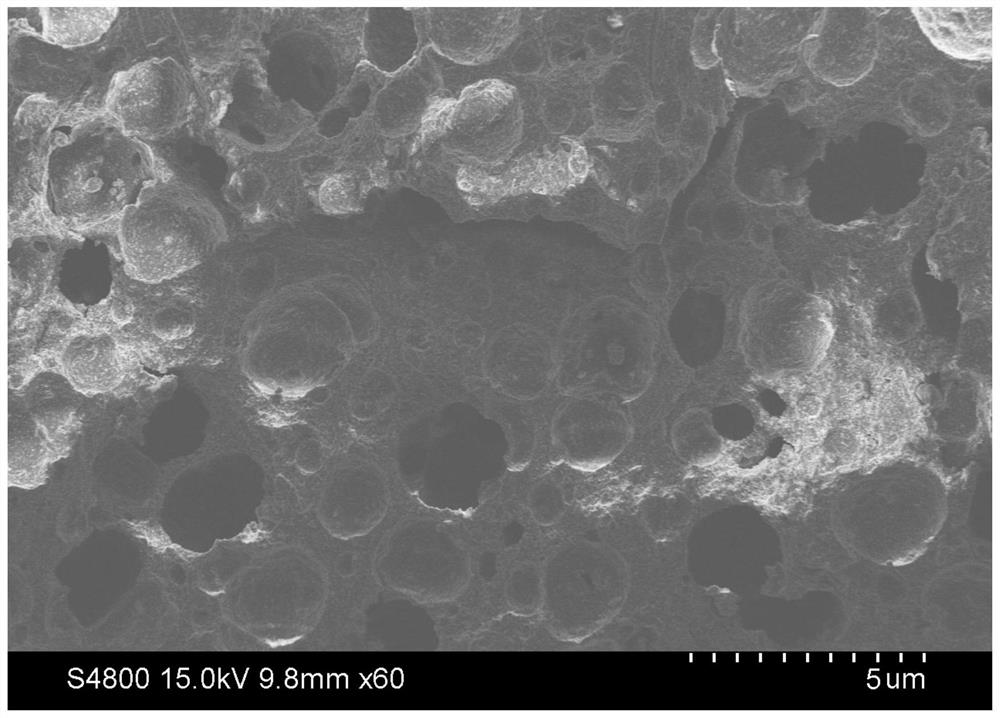

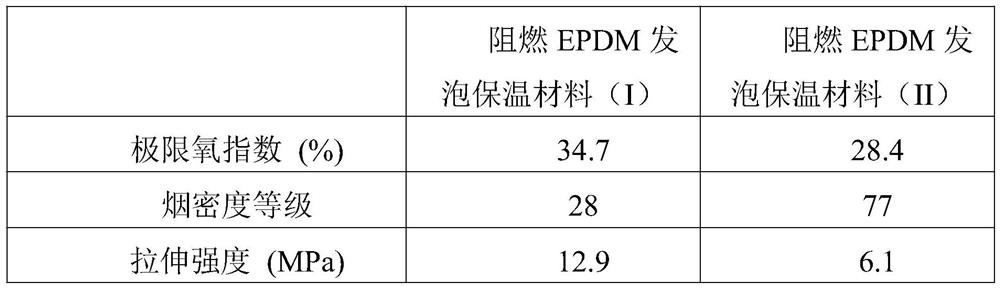

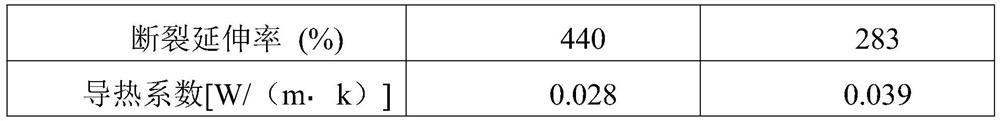

[0029] The scanning electron microscope picture of the section of this kind of flame-retardant EPDM foam insulation material is as follows figure 1 As shown, it includes 100 parts by mass of EPDM, 10-40 parts of naphthenic oil, 5-25 parts of carbon black, 5-25 parts of intumescent flame retardant microparticles, 5-30 parts of modified hydrotalcite, 5 parts ~15 parts of nano-silica, 2.0-6.5 parts of vulcanizing agent Luperox F40P-SP210, 0.5-3 parts of super-speed vulcanization accelerator SE-2, 1-4.5 parts of nano-zinc oxide, 1-3 parts of zinc stearate, 1-3 parts 2 parts of stearic acid, 1.5-4.5 parts of foaming agent H, 0.5-1.5 parts of antioxidant BHT. As a preference, in this embodiment, the intumescent flame retardant microparticles are composed of lignin, ammonium polyphosphate, melamine...

Embodiment 1

[0032]S1, 100 parts of EPDM, 40 parts of naphthenic oil, 25 parts of carbon black, 25 parts of intumescent flame retardant microparticles, 30 parts of modified hydrotalcite, 15 parts of nano silicon dioxide, 1 part of nano zinc oxide, 1 part Zinc stearate, 1 part of stearic acid, 1.5 parts of blowing agent H, 0.5 part of antioxidant BHT were added to the internal mixer and mixed for 12 minutes; as a preference, in this embodiment, the specific preparation of modified hydrotalcite The method is as follows: uniformly disperse the hydrotalcite in the water phase, add a certain amount of sodium dodecylsulfonate and ammonium molybdate, stir and react at 65-95 DEG C for 6-18 hours, and separate to obtain the modified hydrotalcite. And the hydrotalcite, sodium dodecylsulfonate and ammonium molybdate are 100 parts by mass of hydrotalcite, 5-20 parts of sodium dodecylsulfonate and: 1-8 parts of ammonium molybdate, expansion type The specific preparation method of flame retardant microp...

Embodiment 2

[0037] S1, 100 parts of EPDM, 10 parts of naphthenic oil, 5 parts of carbon black, 5 parts of intumescent flame retardant particles, 5 parts of modified hydrotalcite, 5 parts of nano silicon dioxide, 4.5 parts of nano zinc oxide, 3 parts Zinc stearate, 2 parts of stearic acid, 4.5 parts of blowing agent H, 1.5 parts of antioxidant BHT were added to the internal mixer and mixed for 12 minutes; as a preference, in the present embodiment, the specific The preparation method is as follows: uniformly disperse the hydrotalcite in the water phase, add a certain amount of sodium dodecylsulfonate and ammonium molybdate, stir and react at 65-95°C for 6-18 hours, and separate to obtain the modified hydrotalcite. And the hydrotalcite, sodium dodecylsulfonate and ammonium molybdate are 100 parts by mass of hydrotalcite, 5-20 parts of sodium dodecylsulfonate and: 1-8 parts of ammonium molybdate, expansion type The specific preparation method of flame retardant microparticles is: put lignin,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com