Iron oxide/aluminum oxide compound as well as preparation method and application thereof

A technology of alumina and iron oxide, which is applied in the field of viscosity reduction of heavy oil, can solve the problems of low viscosity reduction efficiency of heavy oil, high content of heavy components in heavy oil, poor thermal stability, etc., and achieve good degradation performance, good catalytic activity, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

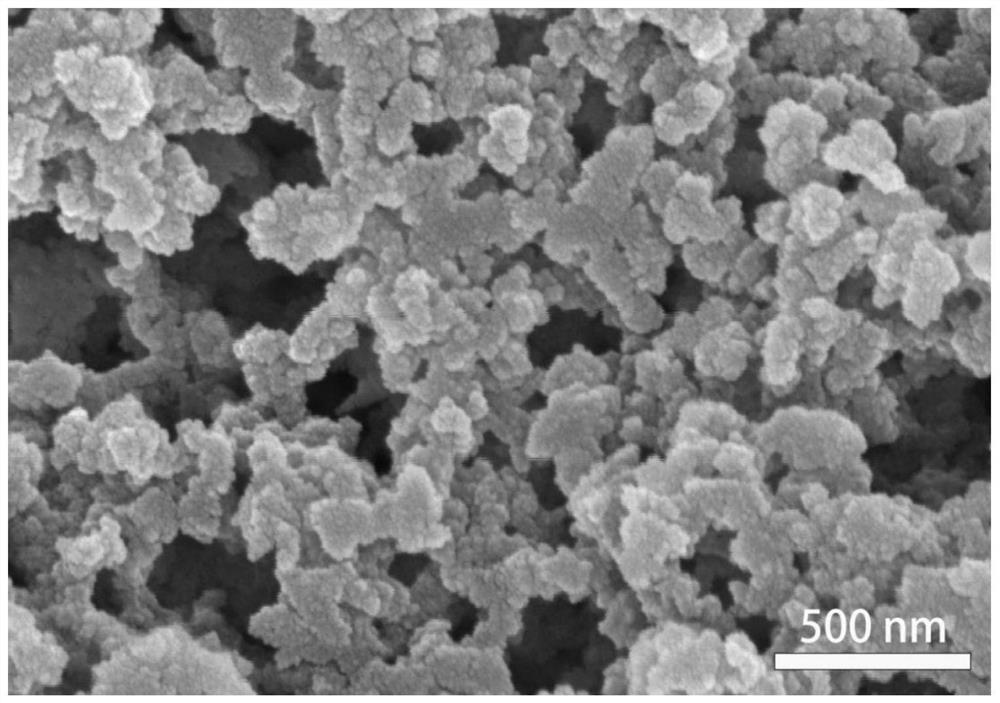

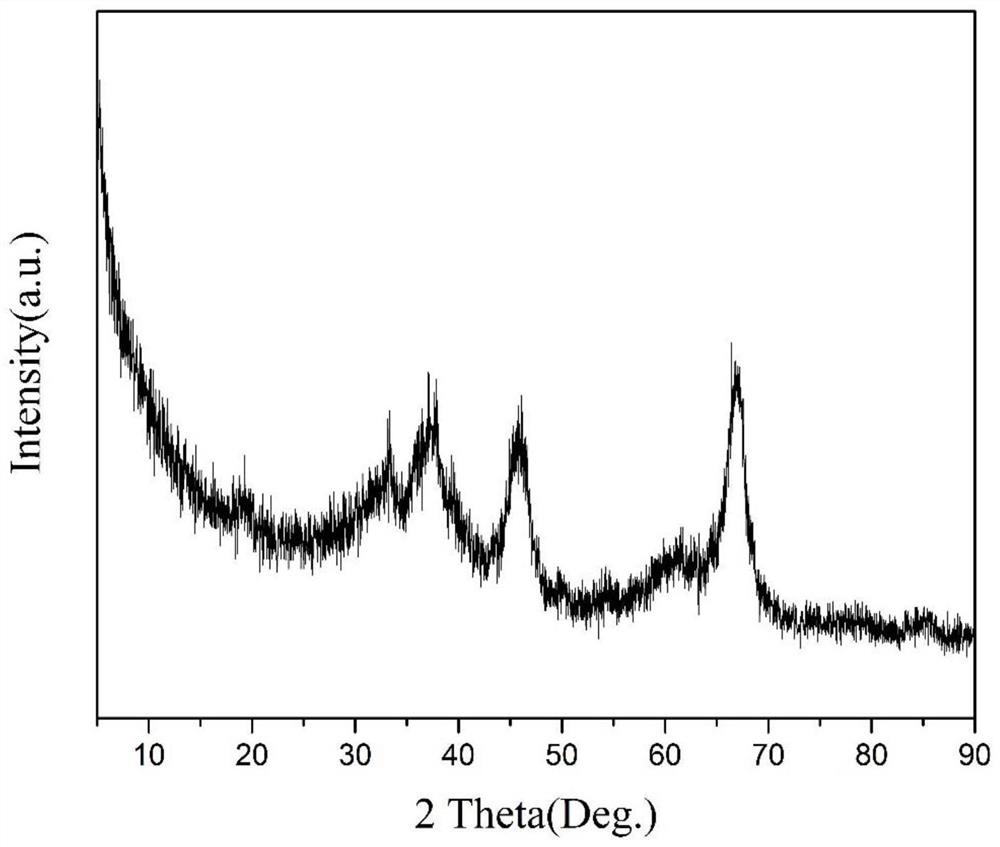

[0023] This specific embodiment provides a kind of preparation method of iron oxide / alumina composite, comprises the following steps:

[0024] S1, the Fe 2 o 3 Nanoparticles are dispersed in ethanol solution and ultrasonically treated for 10-30min, then phase separation agent is added sequentially until completely dissolved, then aluminum salt is added in an ice bath environment and stirred for 20min-40min until completely dissolved, then condensate is added under normal temperature and pressure conditions The gel inducer was vigorously stirred for 5min to 10min to obtain a mixed sol solution; the Fe 2 o 3 The mass of nanoparticles is 1-10% of the mass of the aluminum salt; the mass ratio of the phase separation agent, the aluminum salt and the gel inducing agent is (0.06-0.12): (4.26-4.38): ( 3.05~3.17); The phase separation agent is polyethylene oxide, preferably with a relative molecular mass of 1×10 6 Polyethylene oxide; the aluminum salt is aluminum chloride, further,...

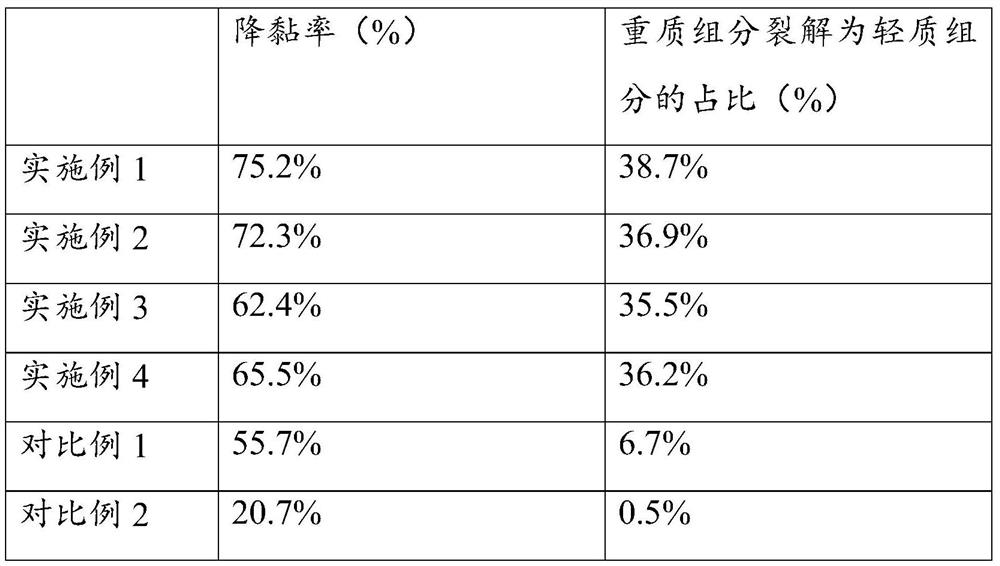

Embodiment 1

[0031] This embodiment proposes an iron oxide / alumina composite, which is prepared by the following steps:

[0032] S1, the Fe 2 o 3 Nanoparticles were dispersed in ethanol solution and ultrasonically treated for 30 min, and then phase separation agent polyethylene oxide (relative molecular mass 1×10 6 ) to completely dissolve, then add crystalline aluminum chloride in an ice-bath environment and stir for 20 minutes until completely dissolved, then add the gel inducer propylene oxide under normal temperature and pressure conditions and stir vigorously for 5 minutes to obtain a mixed sol solution; the Fe 2 o 3 The quality of nanoparticles is 5% of the quality of the aluminum salt; the mass ratio of the polyethylene oxide, the crystalline aluminum chloride and the propylene oxide is 0.12:4.38:3.17; the volume of ethanol in the ethanol solution The concentration is 50%;

[0033] S2. Put the mixed sol solution into a sealed test tube and perform sol-gel conversion at 50°C for ...

Embodiment 2

[0037] This embodiment proposes an iron oxide / alumina composite, which is prepared by the following steps:

[0038] S1, the Fe 2 o 3 Nanoparticles were dispersed in ethanol solution and ultrasonically treated for 20 min, and then phase separation agent polyethylene oxide (relative molecular mass 1×10 6 ) to completely dissolve, then add crystalline aluminum chloride in an ice-bath environment and stir for 40min until completely dissolved, then add the gel-inducing agent propylene oxide under normal temperature and pressure conditions and stir vigorously for 10min to obtain a mixed sol solution; the Fe 2 o 3 The quality of nanoparticles is 8% of the quality of the aluminum salt; the mass ratio of the polyethylene oxide, the crystalline aluminum chloride and the propylene oxide is 0.06:4.26:3.05; the volume of ethanol in the ethanol solution The concentration is 40%;

[0039] S2. Put the mixed sol solution into a sealed test tube and perform sol-gel conversion at 45°C for 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com