Antibacterial and antiviral formaldehyde-removing antifouling agent and preparation method thereof, glazed tile and preparation method thereof

A formaldehyde-removing and anti-virus technology, applied in anti-fouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of short anti-bacterial and anti-virus time, easy to explode, etc., and achieve longer effective sterilization time , Prolong the effect of effective sterilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A preparation method of an antibacterial and antiviral formaldehyde-removing antifouling agent, which is used to prepare the above-mentioned antibacterial and antiviral formaldehyde-removing antifouling agent, comprising the following steps:

[0054] (1) Mix the modified hematilite, the stable chlorine dioxide solution and the silver diammine hydroxide solution evenly according to the formula ratio, and then dry them to obtain the modified hematilite immobilized silver chloride fine powder;

[0055] (2) Mix the modified hematilite-supported silver chloride fine powder, hydroxyl-terminated dimethylsiloxane, water-based aliphatic polyurethane and dispersant according to the formula ratio to obtain an antibacterial, antiviral, formaldehyde-removing and antifouling agent.

[0056] In one embodiment of the present invention, the specific step of step (1) is to mix the modified hematilite, the stable chlorine dioxide solution and the silver diammine hydroxide solution accordin...

Embodiment 1-5

[0072] An antibacterial, antiviral, formaldehyde-removing and antifouling agent. The raw materials of the antifouling agent include 10-20 parts of modified staphilite immobilized silver chloride fine powder, 50-70 parts of hydroxyl-terminated dimethylsiloxane, 10-20 parts 20 parts of water-based aliphatic polyurethane and 1-2 parts of dispersant; wherein, the fineness of the modified staphilite immobilized silver chloride fine powder is 1000 mesh;

[0073] Wherein, the modified hematilite immobilized silver chloride fine powder is prepared from 10-30 parts of modified hematilite, 50-70 parts of stable chlorine dioxide solution and 5-20 parts of diammine silver hydroxide solution. Wherein, the modified hematilite is sulfuric acid modified hematilite.

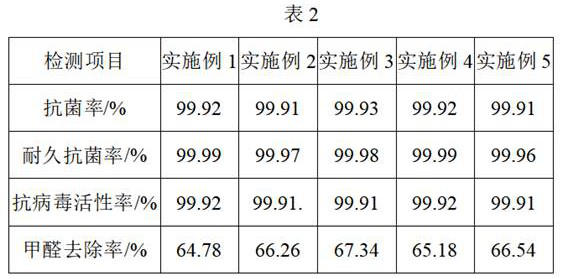

[0074] Concrete, the raw material formula of antifouling agent among the embodiment 1~5 is as shown in following table 1:

[0075]

[0076] The preparation method of antibacterial antiviral formaldehyde antifouling agent in t...

Embodiment 6

[0087] The raw material formula ratio of antibacterial and antiviral formaldehyde-removing antifouling agent in embodiment 6 ~ 8 is identical with embodiment 2, and difference is, the glazed tile of embodiment 6 ~ 8 is non-glazed tile, and wherein embodiment 6 adopts spraying Antibacterial and antiviral formaldehyde-removing antifouling agent is coated on the surface of this non-glazed tile by the mode of antibacterial; Embodiment 7 adopts the mode of brushing and antibacterial antiviral formaldehyde-removing antifouling agent is coated on the surface of this non-glazed tile; Example 8 The method of immersion is to apply the antibacterial, antiviral, formaldehyde-removing and antifouling agent on the surface of the non-glazed tile.

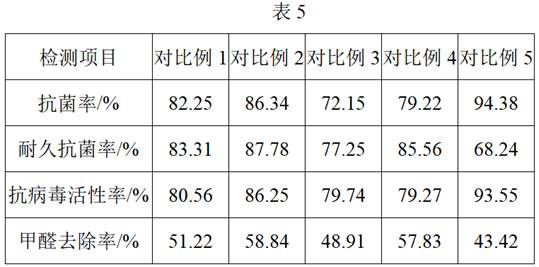

[0088] Using the above method, antibacterial and antiviral formaldehyde-removing glazed tiles were prepared, and the obtained antibacterial and antiviral formaldehyde-removing glazed tiles were prepared according to JC / T 897-2014 "Antibacterial Per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com