Recovery method and application of lithium iron phosphate waste

A recovery method, lithium iron phosphate technology, applied in the field of lithium iron phosphate waste recycling, can solve the problems of large consumption of reagents, high cost, uneconomical, etc., achieve high value-added resource recovery, ease the pressure of processing, and recover high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The recovery method of the lithium iron phosphate waste material of the present embodiment may further comprise the steps:

[0045] (1) Slurry lithium iron phosphate waste and water at a solid-to-liquid ratio of 5:1, add 30% liquid caustic soda to adjust the pH to 8.2, heat and react at 60°C for 120 minutes, and filter and separate after the reaction to obtain a filter residue ;

[0046] (2) Wash and dry the filter residue, then add the dried filter residue into 2mol / L sulfuric acid solution, stir and react at 80°C for 3h, separate liquid and solid, and save the filtrate (liquid iron);

[0047] (3) dissolving oxalic acid in deionized water to configure 10% oxalic acid solution, adding 10% ethanol as surfactant, and dissolving oxalic acid;

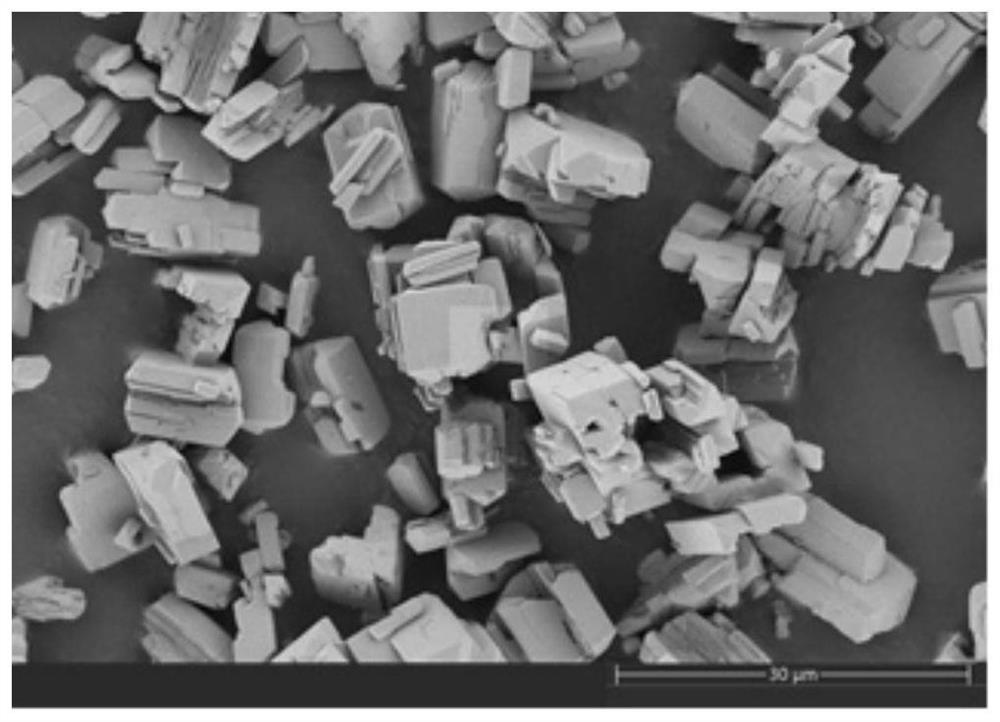

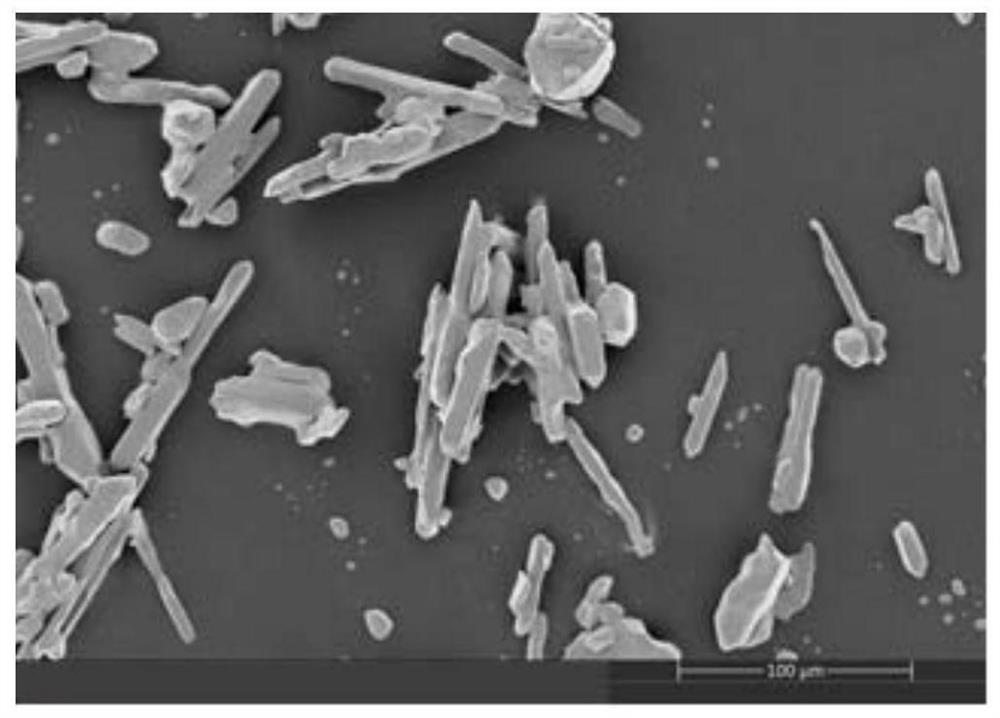

[0048] (4) by Fe 2+ :C 2 o 4 2- The molar ratio is 1:1.3, under stirring at 70°C, continuously add oxalic acid solution to molten iron for 2 hours, after the oxalic acid solution is added, stop stirring, and age at 70°C for 5 hour...

Embodiment 2

[0052] The recovery method of the lithium iron phosphate waste material of the present embodiment may further comprise the steps:

[0053] (1) Slurry lithium iron phosphate waste and water at a solid-to-liquid ratio of 3:1, add 30% liquid caustic soda to adjust the pH to 8.5, heat and react at 55°C for 150 minutes, and filter and separate after the reaction to obtain a filter residue ;

[0054] (2) Wash and dry the filter residue, add the dried filter residue into 2mol / L sulfuric acid solution, stir and react at 80°C for 3h, separate the liquid and solid, and save the filtrate (liquid iron);

[0055] (3) dissolving oxalic acid in deionized water to configure 10% oxalic acid solution, adding 10% ethanol as surfactant, and dissolving oxalic acid;

[0056] (4) by Fe 2+ :C 2 o 4 2- The molar ratio is 1:1.3. Continue to add oxalic acid solution to molten iron at 80°C under stirring for 2 hours. After the oxalic acid solution is added, stop stirring and age at 80°C for 6 hours....

Embodiment 3

[0060] The recovery method of the lithium iron phosphate waste material of the present embodiment may further comprise the steps:

[0061] (1) Slurry lithium iron phosphate waste and water at a solid-to-liquid ratio of 5:1, add 20% liquid caustic soda to adjust the pH to 8.4, heat and react at 65°C for 150 minutes, and filter and separate after the reaction to obtain a filter residue ;

[0062] (2) Wash and dry the filter residue, add the dried filter residue into 2mol / L sulfuric acid solution, stir and react at 80°C for 3h, separate the liquid and solid, and save the filtrate (liquid iron);

[0063] (3) dissolving oxalic acid in deionized water to configure 20% oxalic acid solution, adding 10% ethanol as surfactant, and dissolving oxalic acid;

[0064] (4) by Fe 2+ :C 2 o 4 2- The molar ratio is 1:1.2. Continue to add oxalic acid solution to molten iron at 75°C under stirring for 2 hours. After the oxalic acid solution is added, stop stirring and age at 75°C for 5 hours....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com