Liquid crystal polymer substrate and preparation method thereof

A liquid crystal polymer and substrate technology, applied in circuit substrate materials, printed circuit manufacturing, printed circuit components, etc., can solve problems such as signal loss, achieve difficult signal loss, high bonding strength and tensile strength, and is conducive to high The effect of high-speed transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the above-mentioned liquid crystal polymer substrate, comprising the following steps:

[0044]Coating one of the LCP layers on the surface of one copper foil layer, coating the other LCP layer on the surface of another copper foil layer, removing the solvent at 60-180°C, ℃ yellowing reaction for 9~11h to obtain the first LCP core layer and the second LCP core layer;

[0045] Coating the low dielectric adhesive layer on the surface of the first LCP core layer, drying, pressing the second LCP core on the surface of the low dielectric adhesive layer away from the first LCP core layer layer;

[0046] Winding and aging, the liquid crystal polymer substrate is obtained.

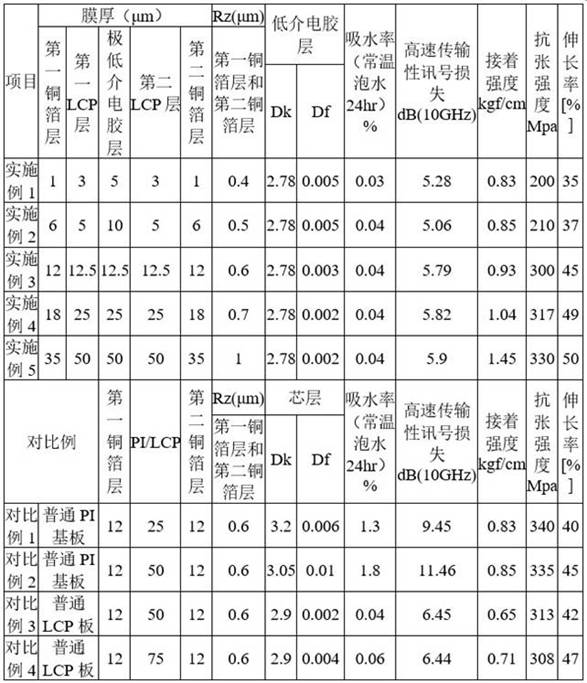

Embodiment 1

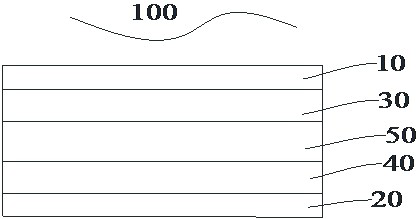

[0048] Please refer to figure 1 As shown, the embodiment of the present invention provides a liquid crystal polymer substrate 100, comprising two layers of copper foil layers and an intermediate core layer disposed between the two layers of copper foil layers, the two layers of copper foil layers are respectively the first copper foil layer a foil layer 10 and a second copper foil layer 20;

[0049] The intermediate core layer includes a layer of low-dielectric adhesive layer, also referred to as the first low-dielectric adhesive layer 50, and two layers of LCP layers, the two layers of LCP layers are respectively the first LCP layer 30 and the second LCP layer 40, The first low dielectric adhesive layer 50 is arranged between the first LCP layer 30 and the second LCP layer 40, the surface of the first LCP layer 30 away from the first low dielectric adhesive layer 50 and The first copper foil layer 10 is bonded and connected, and the surface of the second LCP layer 40 away fr...

Embodiment 2

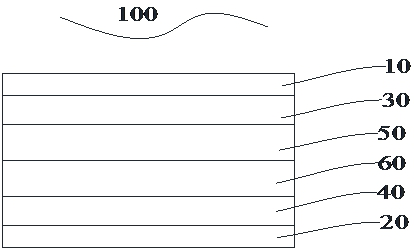

[0057] An embodiment of the present invention provides a liquid crystal polymer substrate, comprising two copper foil layers and an intermediate core layer disposed between the two copper foil layers, the two copper foil layers are respectively the first copper foil layer and the second copper foil layer. Two copper foil layers;

[0058] The middle core layer includes a layer of low dielectric glue layer and two layers of LCP layers, the two layers of LCP layers are respectively the first LCP layer and the second LCP layer, and the low dielectric glue layers are all arranged on the first LCP layer. layer and the second LCP layer, the surface of the first LCP layer facing away from the low dielectric adhesive layer is bonded and connected to the first copper foil layer, and the second LCP layer is away from the low dielectric adhesive layer The surface of the layer is attached and connected to the second copper foil layer;

[0059] The thickness of each layer of copper foil la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com