Active control method for urea crystallization risk of Urea-SCR system

An active control and crystallization technology, applied to the electronic control of exhaust treatment devices, engine components, combustion engines, etc., can solve the problems of poor engine economy and emission characteristics, low exhaust temperature, environmental pollution, etc., and achieve sustainable The effect of short time and low fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

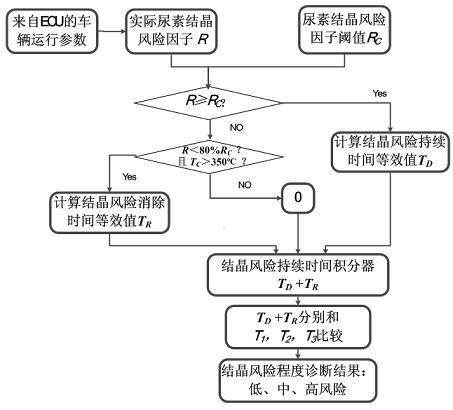

[0022] The working principle of the Urea-SCR system urea crystallization risk active control module in this embodiment is as follows image 3 shown.

[0023] After the crystallization risk active control module receives the diagnosis result from the crystallization risk online diagnosis module, it will trigger the instrument to display the change curve of urea crystallization risk coefficient in real time. The ordinate of the graph is the specific value output by the current risk duration counter, and the abscissa is The corresponding time is updated every 2s to help the driver confirm the current crystallization risk change law of the vehicle, and at the same time clarify whether the operating condition adjustment strategy adopted meets the requirements for reducing the urea crystallization risk. According to different risk levels, the crystallization risk active control module will adopt different risk control strategies.

[0024] In the state of low crystallization risk, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com