Rapid and efficient lithium ion battery negative electrode homogenate stirring method

A technology of a lithium-ion battery and a stirring method, which is applied in the field of lithium-ion batteries, can solve the problems of easy holding of paddles at high speed, easy overload alarm of motor current, large influence on efficiency and equipment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

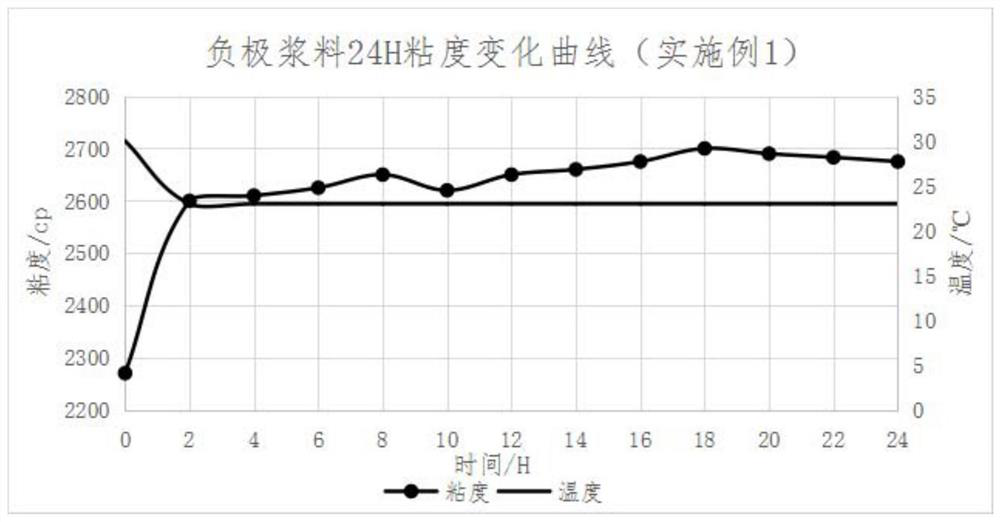

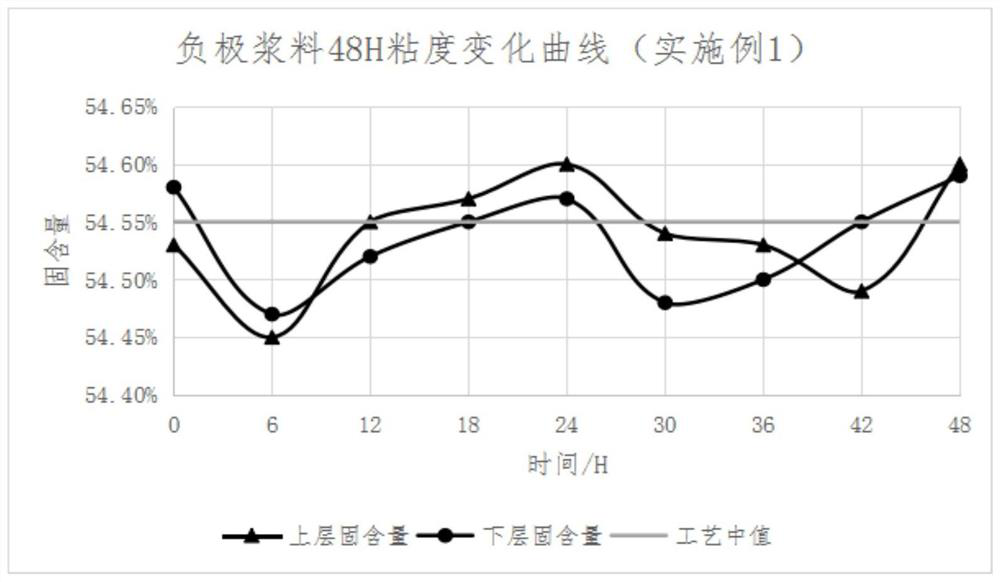

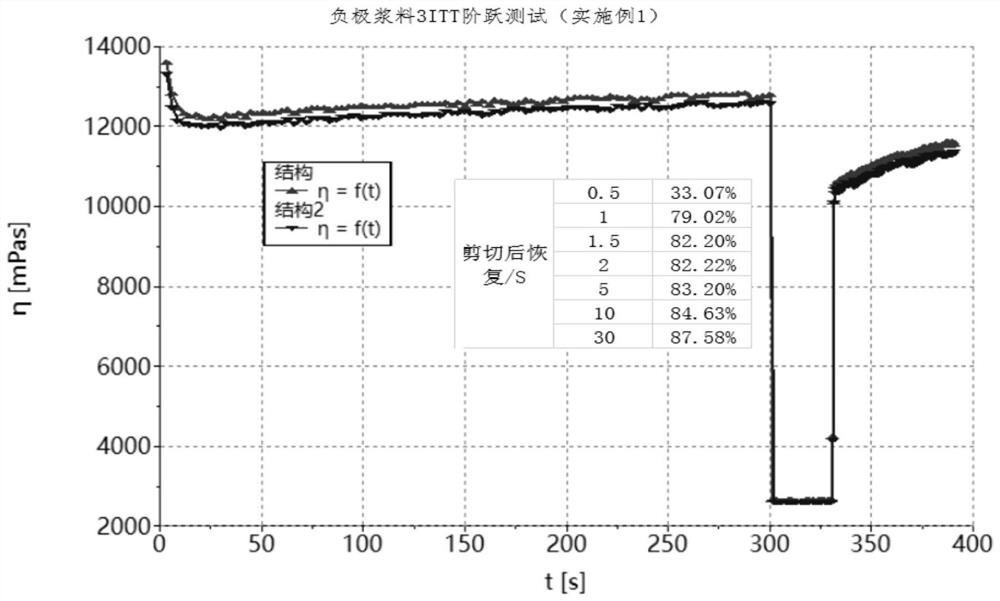

Embodiment 1

[0047] A fast and efficient lithium-ion battery negative electrode homogenate stirring method, comprising the following steps:

[0048] 1) Prepare raw materials according to parts by mass: 100 parts of graphite, 2.0 parts of conductive agent SP, 2.5 parts of styrene-butadiene rubber, 1.5 parts of CMC, 85 parts of water, 1 part of N-methylpyrrolidone; the styrene-butadiene rubber has a solid content of 50 % of styrene-butadiene rubber suspension;

[0049] Stir carboxymethylcellulose sodium (CMC) and deionized water according to the formula ratio to make glue. The glue making process is as follows: first add 80% deionized water, then evenly add the formula amount of CMC, and then the remaining formula amount is 20%. Spray and add deionized water, and stir at 1008rpm while spraying. After 10 minutes of spraying, continue to stir at this speed for a total of 90 minutes, and then stir at 864rpm for 30 minutes. Vacuum degassing treatment, the vacuum degree is - 95kpa to -85kpa, get...

Embodiment 2

[0062] A fast and efficient negative electrode homogenization process for lithium ion batteries, comprising the following steps:

[0063] 1) 1) Prepare each raw material according to parts by mass: 100 parts of graphite, 1.0 parts of conductive agent SP, 2.0 parts of styrene-butadiene rubber, 1.5 parts of CMC, 82 parts of water, 1 part of N-methylpyrrolidone; the styrene-butadiene rubber is Styrene-butadiene rubber suspension with a solid content of 50%;

[0064] Stir carboxymethyl cellulose sodium (CMC) and deionized water according to the formula ratio to make glue. The glue making process is to add 80% deionized water first, add the formula amount of CMC evenly, and then spray the remaining 20% deionized water. Stir at a speed of 1008rpm while spraying. After 10 minutes of spraying, continue to stir at this speed for a total of 90 minutes, then stir at a speed of 864rpm for 30 minutes. The glue is vacuumed and degassed. The vacuum degree is -95kpa to -85kpa. The resultin...

Embodiment 3

[0077] A fast and efficient negative electrode homogenization process for lithium ion batteries, comprising the following steps:

[0078] 1) 1) 1) Prepare raw materials according to parts by mass: 100 parts of graphite, 2.5 parts of conductive agent SP, 2.5 parts of styrene-butadiene rubber, 1.6 parts of CMC, 85 parts of water, 1 part of N-methylpyrrolidone; The rubber is a suspension of styrene-butadiene rubber with a solid content of 50%;

[0079] Stir carboxymethylcellulose sodium (CMC) and deionized water according to the formula ratio to make glue. The glue making process is to add 80% deionized water first, add 100% CMC evenly, and then spray the remaining 20% deionized water. Stir at a speed of 1008rpm while spraying. After 10 minutes of spraying, continue to stir at this speed, and then stir at a speed of 864rpm for 30 minutes. The glue is vacuumed and degassed. The glue solution is divided into four parts, namely A, B, C and D, accounting for 51%, 10%, 9% and 30% r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com