Frozen microorganism soil mixing pile

A technology for mixing piles and microorganisms, which is applied to the field of frozen microbial soil mixing piles, can solve the problems of engineering properties and adverse effects of adjacent buildings, poor frost resistance and insufficient shear resistance of cement-soil mixing piles, and achieves inhibition of frost heave. The effect of melting and settling phenomenon, improving impermeability and improving microbial soil fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

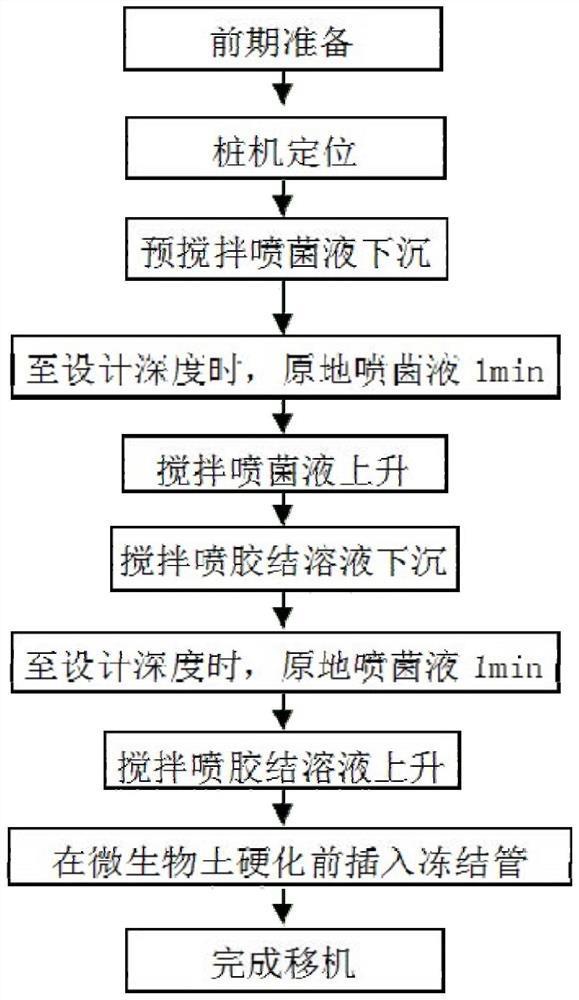

Method used

Image

Examples

Embodiment 1

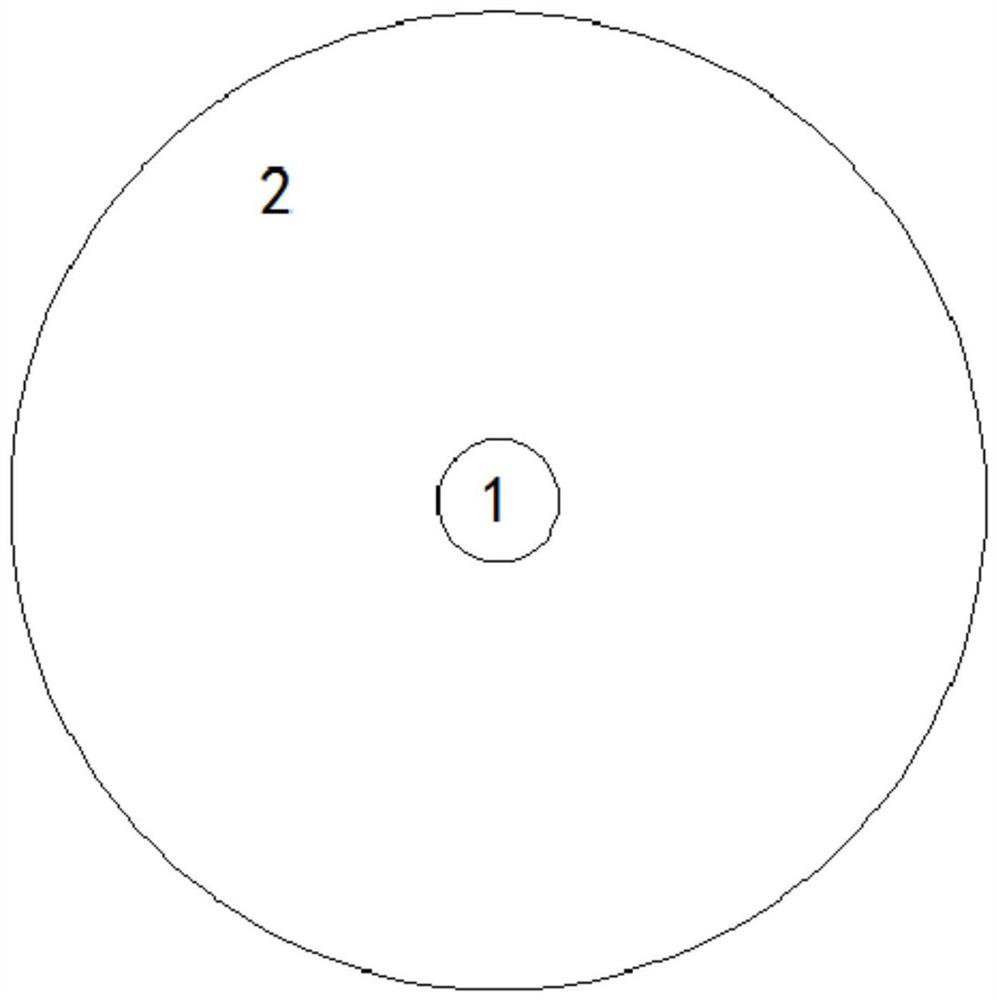

[0035] A frozen microbial soil stirring pile, comprising a freezing pipe and a microbial soil stirring pile body, a freezing pipe is provided at the center of the microbial soil stirring pile body, characterized in that the microbial soil stirring pile body includes the following parts by weight Raw materials: 250 parts of soft soil, 10 parts of admixture, 4 parts of bacterial solution and 25 parts of cementing solution.

[0036] The bacterial liquid is composed of Bacillus pasteurii, Pseudomonas oryzae and nutrient salt solution, and the concentration of Bacillus pasteurianus in the bacterial liquid is OD 600 The value is 0.5, the concentration OD of Pseudomonas oryzae in the bacterial solution 600 The value is 0.3;

[0037] Each 1 liter of the nutrient salt solution includes the following components: 6g soybean peptone, 14g tryptone, 5g sodium chloride, 18g urea, 3g seaweed polysaccharide; the pH value of the nutrient salt solution is 7.15.

[0038] The admixture is prepar...

Embodiment 2

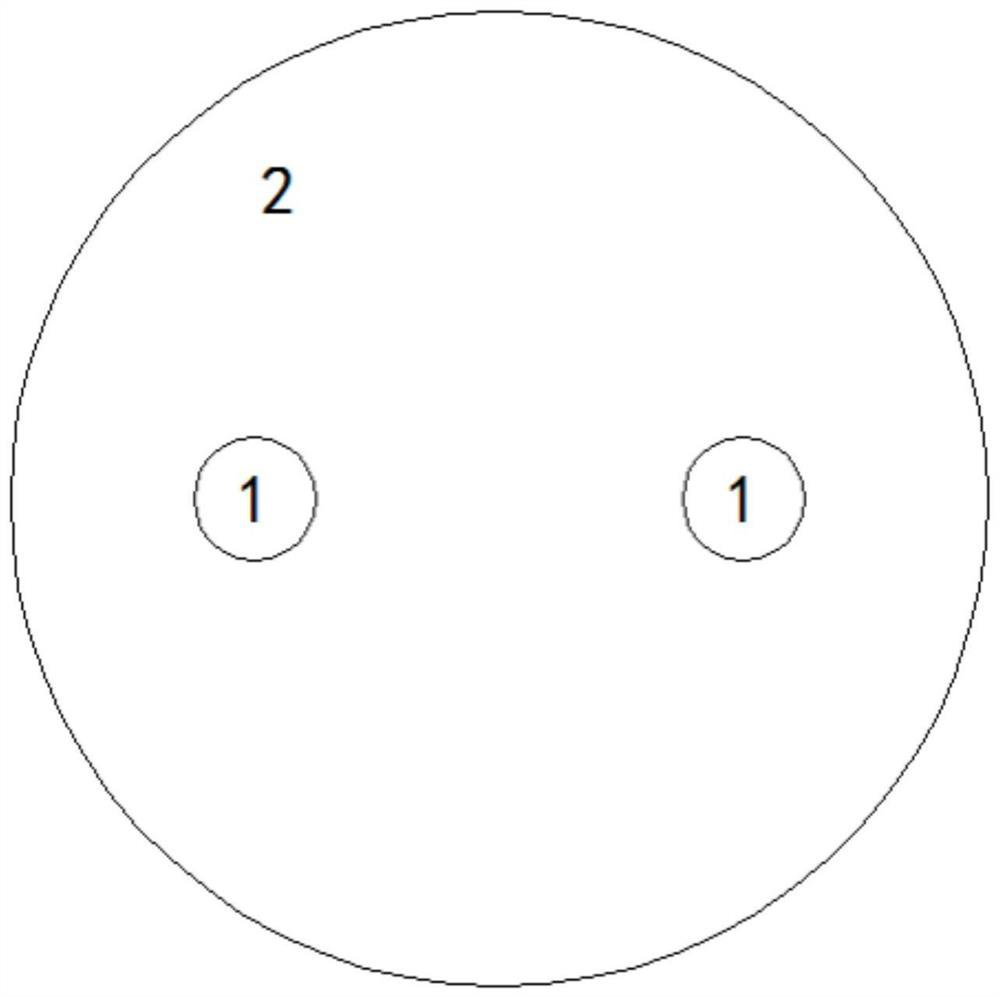

[0046] A frozen microbial soil stirring pile, comprising a freezing pipe and a microbial soil stirring pile body, two freezing pipes are arranged at the center of the microbial soil stirring pile body, and it is characterized in that the microbial soil stirring pile body includes the following weight Raw materials: 380 parts of soft soil, 11 parts of admixture, 6 parts of bacterial solution and 24 parts of cementing solution.

[0047] The bacterial liquid is composed of Bacillus pasteurii, Pseudomonas oryzae and nutrient salt solution, and the concentration of Bacillus pasteurianus in the bacterial liquid is OD 600 The value is 0.6, the concentration OD of Pseudomonas oryzae in the bacterial solution 600 Value is 0.5;

[0048] Each 1 liter of the nutrient salt solution includes the following components: 7g soybean peptone, 15g tryptone, 6g sodium chloride, 21g urea, 4g seaweed polysaccharide; the pH value of the nutrient salt solution is 7.25.

[0049]The admixture is prepar...

Embodiment 3

[0057] A frozen microbial soil stirring pile, comprising a freezing pipe and a microbial soil stirring pile body, two freezing pipes are arranged at the center of the microbial soil stirring pile body, and it is characterized in that the microbial soil stirring pile body includes the following weight Parts of raw materials: 400 parts of soft soil, 12 parts of admixture, 8 parts of bacterial solution and 25 parts of cementing solution.

[0058] The bacterial liquid is composed of Bacillus pasteurii, Pseudomonas oryzae and nutrient salt solution, and the concentration of Bacillus pasteurianus in the bacterial liquid is OD 600 The value is 0.8, the concentration OD of Pseudomonas oryzae in the bacterial solution 600 The value is 0.6.

[0059] Each liter of the nutrient salt solution includes the following components: 8g soybean peptone, 16g tryptone, 8g sodium chloride, 22g urea, 5g seaweed polysaccharide; the pH value of the nutrient salt solution is 7.35.

[0060] The admixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com