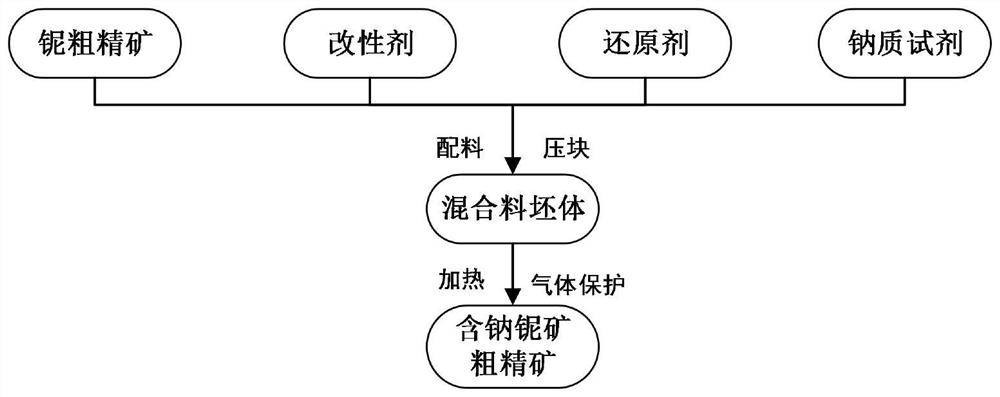

Method for converting niobium minerals in niobium rough concentrate into niobium ore and producing niobium concentrate

A technology for rough concentrate and sodium niobium ore, which is applied in the fields of metallurgy and mineral processing, can solve the problems of high energy consumption, unfavorable industrial application, low content, etc., and achieves the effects of strong adaptability, favorable industrial application and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The niobium rough concentrate with a niobium grade of 2.24% obtained from the pre-selection of niobium-containing raw ore in Bayan Obo is used as the main raw material. The chemical composition is shown in Table 1. The types of niobium-containing minerals include niobium iron ore, ferroniobium rutile, and niobium calcium ore. In this example, the alkalinity is regulated to be 1.5, Na 2 CO 3 The content was adjusted to 0.5%.

[0074] Table 1 Chemical composition of raw materials / wt%

[0075]

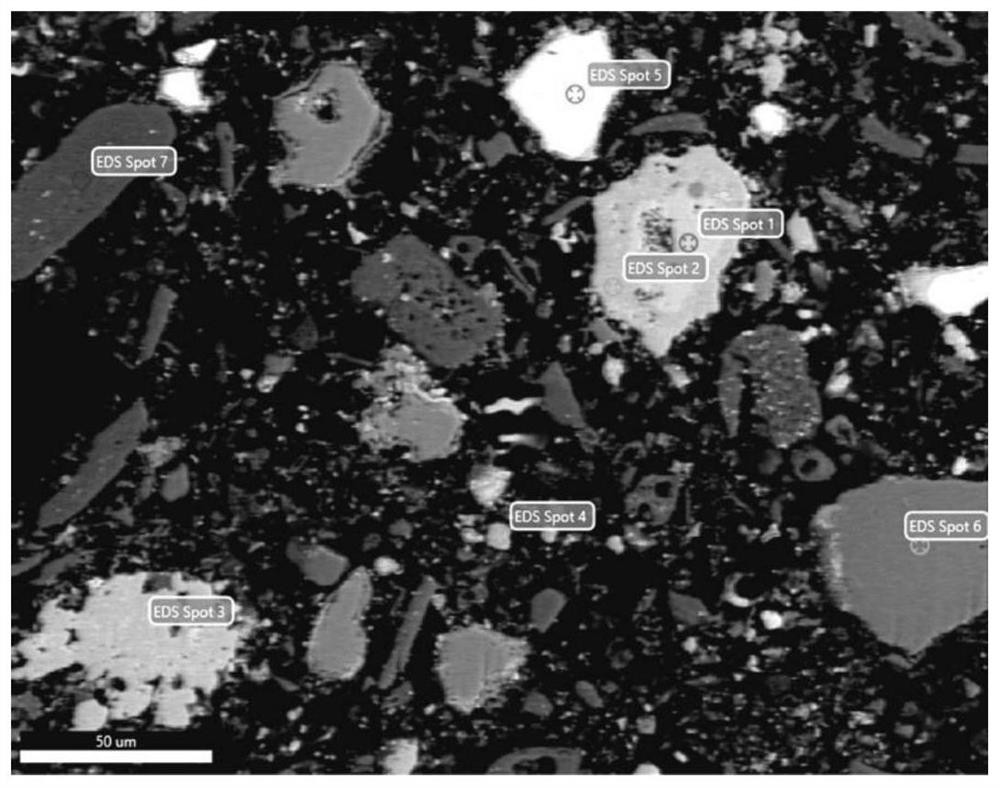

[0076] Take 20g of niobium coarse concentrate and add 1.2g of petroleum coke as a reducing agent. After fully mixing by a pulverizer, add 2mL of 5% PVA solution, and use a press and a mold to shape the mixture to obtain a cylinder with a diameter of Φ30mm. After drying in the oven for 8h, it was placed in a tube furnace, and the N 2 It was calcined at 1000℃ for 60min under the condition of protective gas. After cooling in the furnace, it was found by electron microscope that 5...

Embodiment 2

[0078] The niobium coarse concentrate with a niobium grade of 2.24% obtained by pre-selection of niobium-containing raw ore is used as the main raw material. The chemical composition is shown in Table 1. The types of niobium-containing minerals include niobium iron ore, ferroniobium rutile, and niobium calcium ore. In this example, the alkalinity is regulated to be 1.5, Na 2 CO 3 The content was adjusted to 2%.

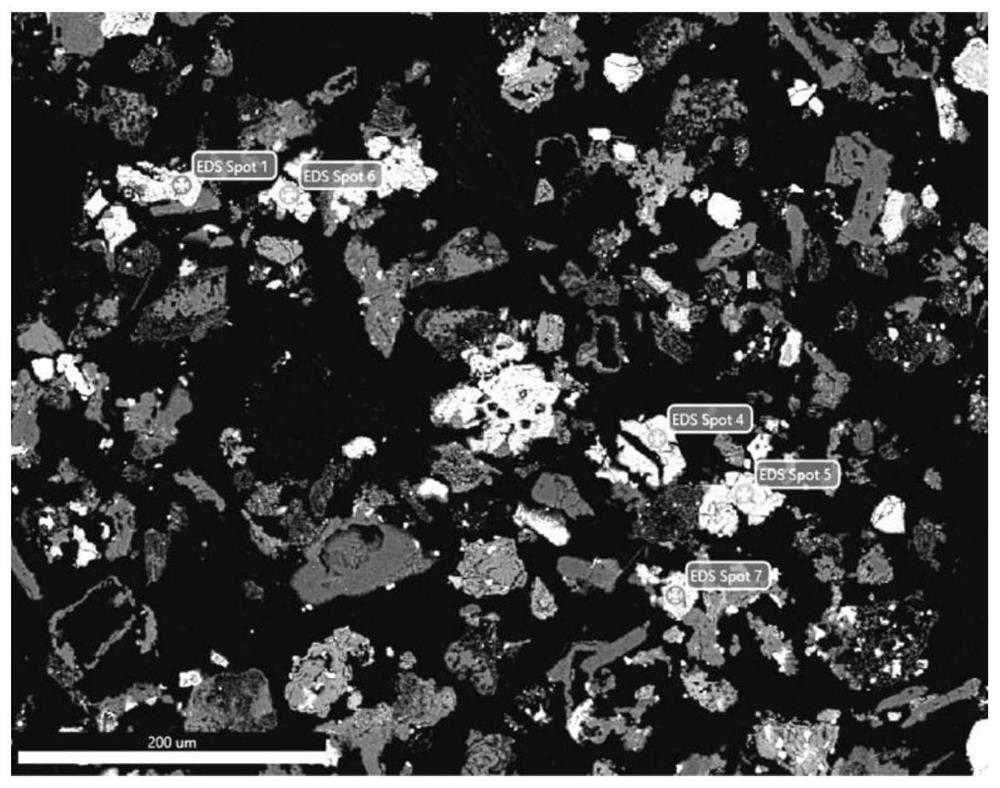

[0079] Take 20g of niobium coarse concentrate, mix with 1.2g of petroleum coke, mix thoroughly with a pulverizer, mix with 2mL of 5% PVA solution, use a press and a mold to shape the mixture to obtain a cylinder with a diameter of Φ30mm, and dry it in an oven After 8h, it was placed in a tube furnace, and N 2 It was roasted at 1000°C for 90min under the condition of protective gas. After cooling in the furnace, it was found by electron microscope that 90% of the niobium minerals were transformed into granular niobium ore with a small amount of Ca, and the grain siz...

Embodiment 3

[0081] The niobium coarse concentrate with a niobium grade of 2.24% obtained by pre-selection of niobium-containing raw ore is used as the main raw material. The chemical composition is shown in Table 1. The types of niobium-containing minerals include niobium iron ore, ferroniobium rutile, and niobium calcium ore. In this example, the alkalinity is regulated to be 1.5, Na 2 CO 3 The content was adjusted to 5%.

[0082] Take 20g of niobium coarse concentrate, mix with 1.2g of petroleum coke, mix thoroughly with a pulverizer, mix with 2mL of 5% PVA solution, use a press and a mold to shape the mixture to obtain a cylinder with a diameter of Φ30mm, and dry it in an oven After 8h, it was placed in a tube furnace, and N 2 It was roasted at 1000 ℃ for 90 min under the condition of protective gas. After cooling in the furnace, it was found by electron microscope that 90% of the niobium minerals were converted into granular Naniobium ore with Ca inclusions, and the grain size was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com