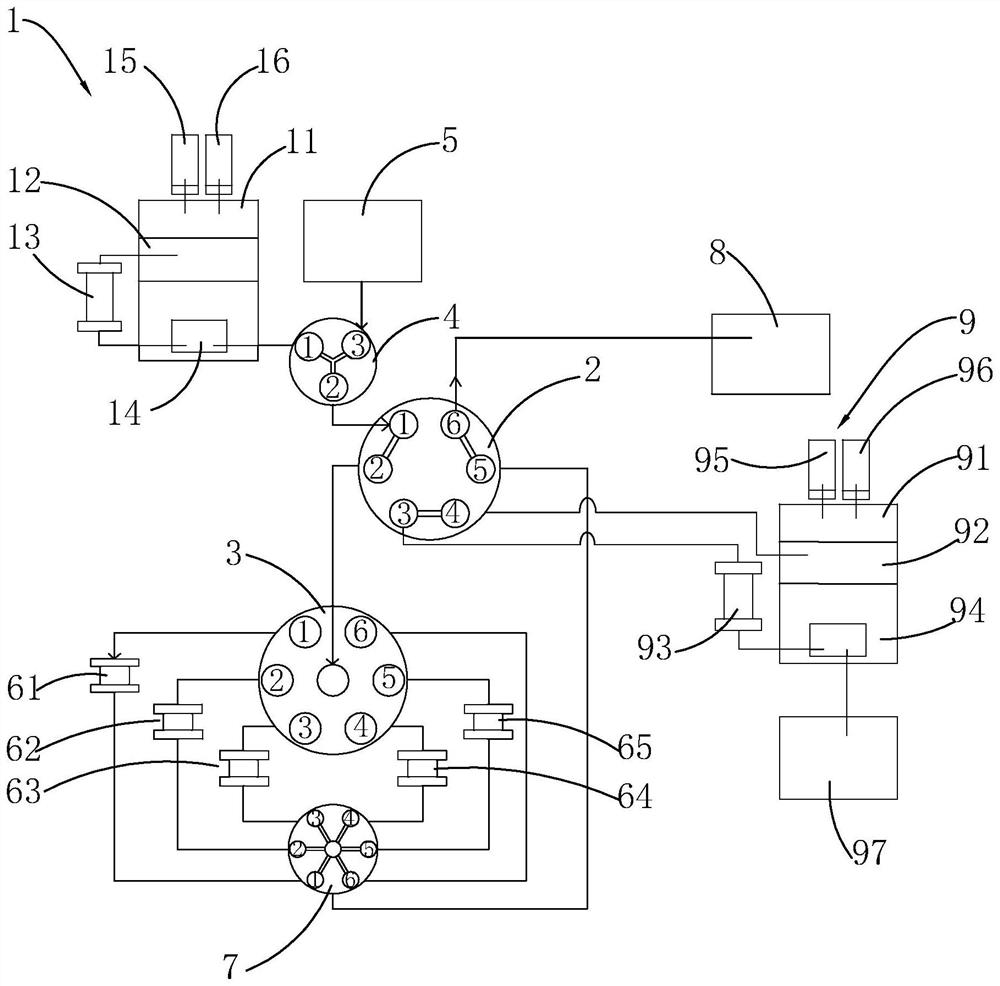

Two-dimensional high-pressure preparative liquid chromatography system and separation and purification method for low-content target components in medicine

A technology for preparing liquid phase and chromatographic systems, applied in the field of separation and purification of target components, can solve problems such as failure to achieve separation effect and separation and purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

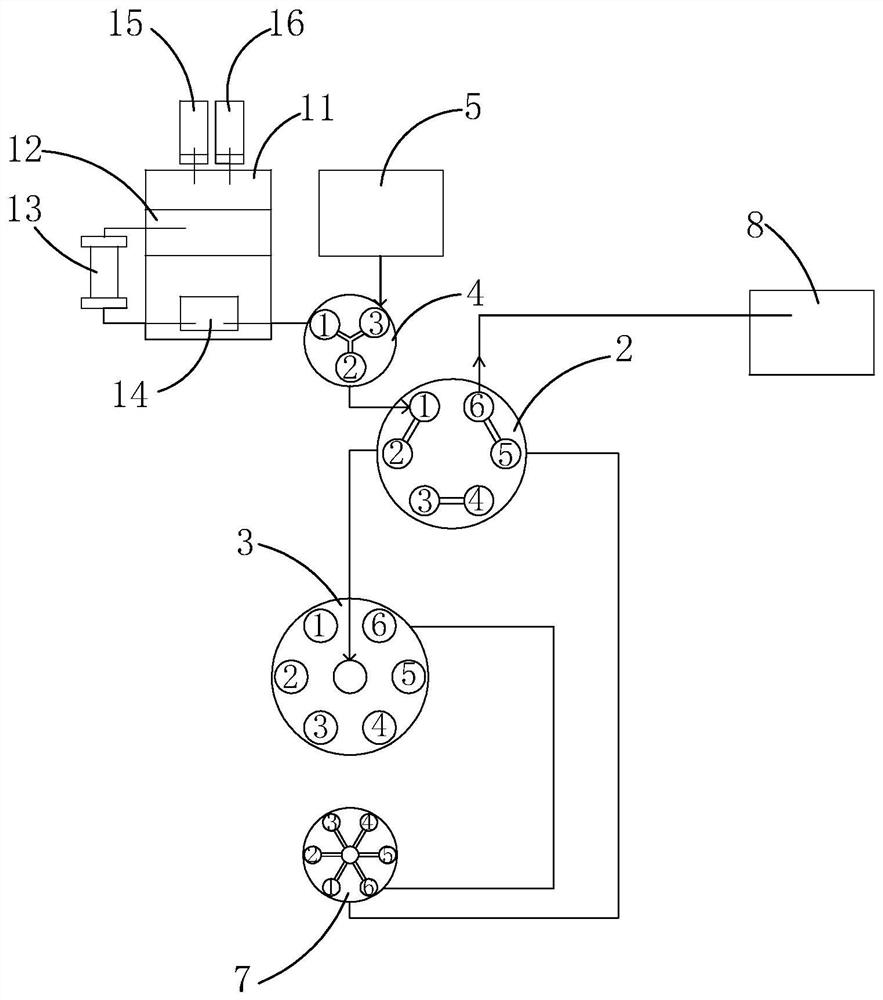

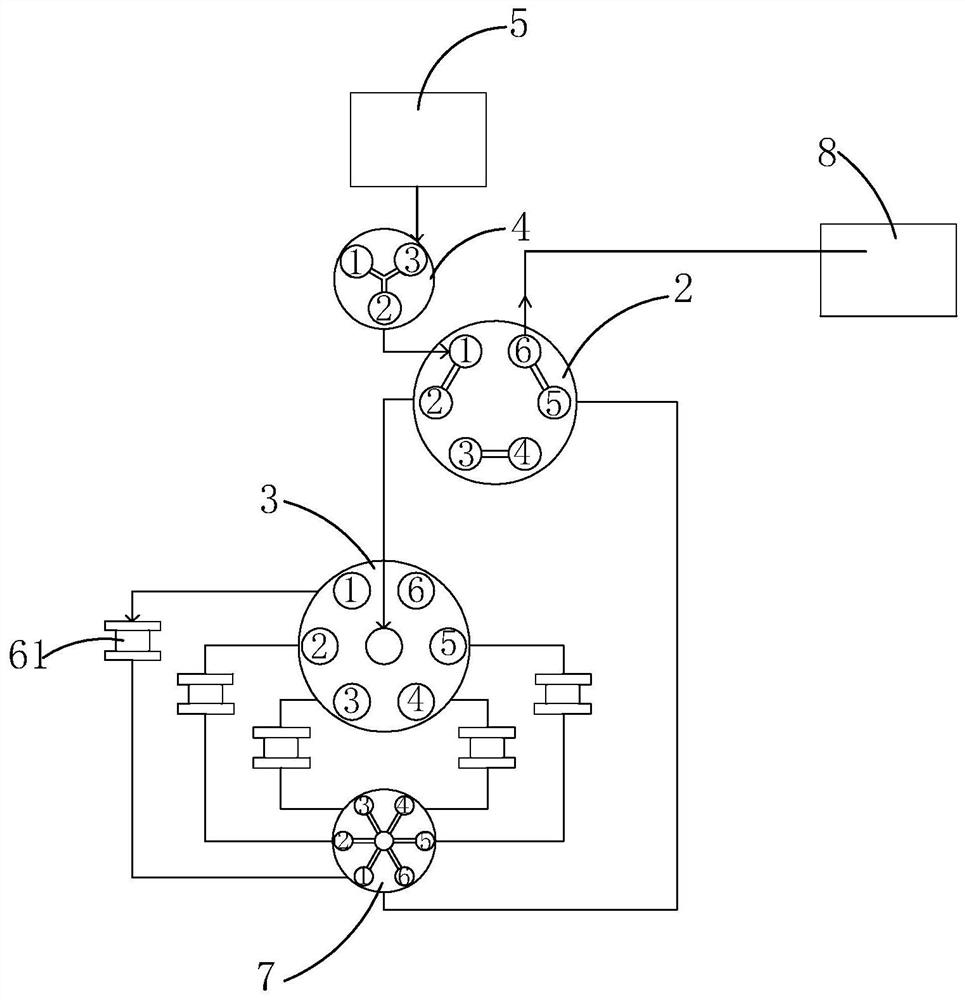

[0109] A method for separating and purifying pharmaceutical impurities by using a two-dimensional high-pressure preparative liquid chromatography system, comprising the following steps:

[0110] S1. The one-dimensional separation column 13 is pre-balanced according to the pipeline connection in (I-I): wherein, the aqueous phase is ultrapure water (adding 0.05% trifluoroacetic acid, v / v), and the organic phase is acetonitrile; then through the software Set the ratio of the water phase to the organic phase, turn on the one-dimensional high-pressure chromatographic pump 11, so that the equilibrium liquid enters the first mixer 12, the one-dimensional separation column 13, and then enters the first detector 14 to carry out pre-balance (system pressure is stable, detection The baseline displayed by the instrument is stable), and the balance liquid finally enters the waste liquid receiving device 8.

[0111] According to the pipeline connection of (I-II), the first trapping column 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com