Preparation method of defect foam graphene loaded transition metal monatomic catalyst

A technology of foamed graphene and transition metals, applied in electrolysis process, electrodes, electrolysis components, etc., can solve the problems of large fossil fuel consumption, greenhouse gas emission, etc., achieve the effect of increasing quantity, improving catalytic activity, and broadening the field of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

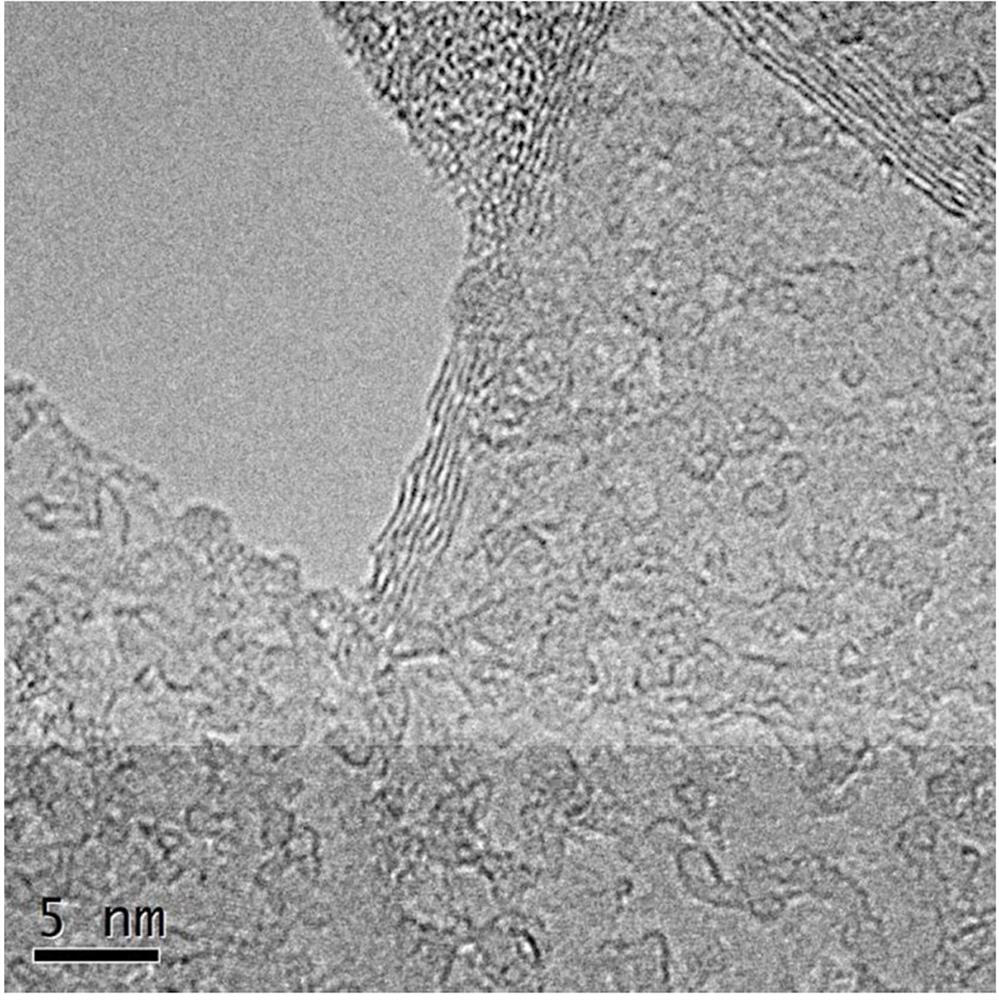

[0032] Take 1 gram of the dried graphene oxide sample, soak it in nitric acid solution for 4 hours, and centrifuge and wash it to neutral with deionized water. It can be seen from the figure that the defective graphene oxide is relatively thin, and there are obvious defects in the morphology.

[0033] Take 100 mg of dried defective graphene oxide and dissolve it in 100 mL of thiourea aqueous solution for ultrasonic dispersion, stir for 6 h, re-disperse in aqueous solution after centrifugation, add 1 ml of 19 mmol / L ferrous sulfate solution for ultrasonic dispersion. The filtered sample was redispersed in the solution and treated with 700W microwave for 1min, the sample turned from yellow to grayish black. The microwaved sample was acid-washed in 3 mol / L HCL solution for 8 hours to remove the particles and impurities inside, and then washed to neutrality. The neutralized sample was prepared into a 40 mL solution, placed in a reaction kettle at 180°C for 6 hours, and freeze-dri...

Embodiment 2

[0039] Take 1 gram of the dried graphene oxide sample, soak it in nitric acid solution for 2 hours, and wash it by centrifugation with deionized water until it becomes neutral.

[0040] Take 100 mg of dried defective graphene oxide and dissolve it in 100 mL of urea aqueous solution for ultrasonic dispersion, stir for 6 h, re-disperse in aqueous solution after centrifugation, and add 3 ml of 15 mmol / L molybdenum chloride solution for ultrasonic dispersion. The filtered sample was redispersed in the solution and treated with 500W microwave for 3min, the sample turned from yellow to grayish black. The sample after microwave was acid-washed in 3 mol / L HCL solution for one day to remove the particles and impurities inside, and then washed to neutrality. The neutralized sample was prepared into a 40 mL solution, placed in a reaction kettle at 180°C for 12 hours, and freeze-dried for 24 hours.

[0041] The freeze-dried samples were placed in a tube furnace with argon at 800°C for tw...

Embodiment 3

[0044] The preparation method is the same as in Example 2, only the transition metal salt is molybdenum chloride, and the performance diagram is shown in the attached Figure 7 , it can be seen from the figure that the synthesis efficiency is the highest at -0.3V (VS.RHE), and its synthetic ammonia yield is 30μgh -1 mgcat -1 , with a Faraday efficiency of 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com