A high-stability colloidal foam that inhibits the oxidation and self-heating of loose coal bodies and its preparation method

A high-stability, coal-body technology, used in ceramic products, mining equipment, earth-moving drilling, etc., can solve the problems of rapid water loss, short three-phase foam stabilization time, and limited oxygen isolation and cooling effect of loose coal bodies. Enhanced effect of air entrainment and expansion foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

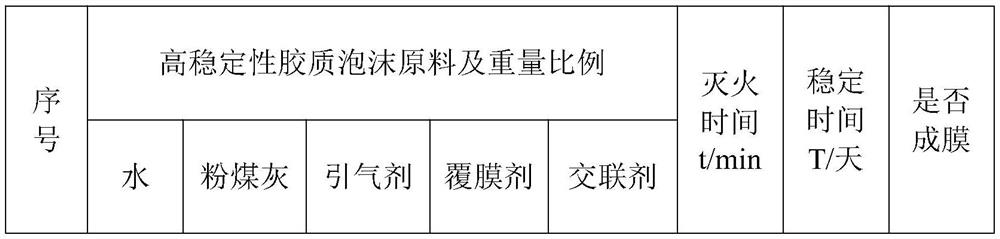

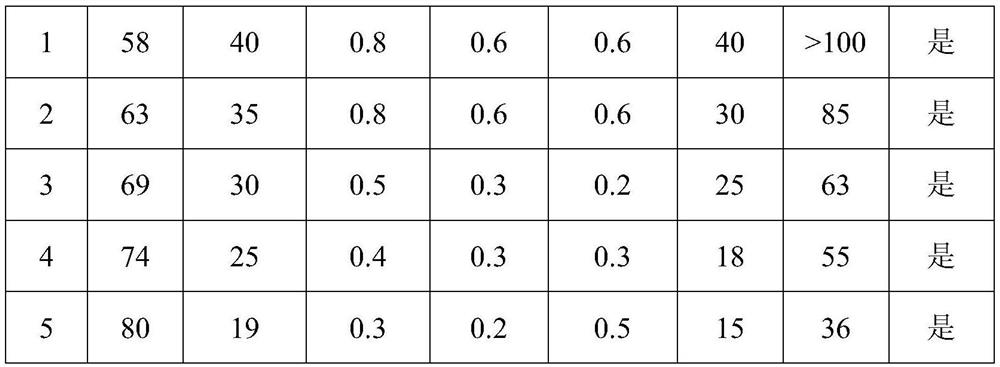

Embodiment 1

[0033] A high-stability colloidal foam that inhibits the self-heating of loose coal oxidation, made of the following raw materials in weight percentage: 58% water, 40% fly ash, 0.8% air-entraining agent, 0.6% film coating agent, cross-linked Agent 0.6%.

[0034] In this embodiment, the preparation method of the high-stability colloidal foam that inhibits the self-heating of loose coal oxidation, the specific steps are: firstly weigh the fly ash and the coating agent in proportion, fully disperse and dissolve them in water, and stir to obtain uniform fly ash suspension; secondly, add the air-entraining agent to the above-mentioned fly ash suspension in proportion, stir rapidly for 5-10 minutes, and make fly ash foam through the process of air-entraining foaming expansion; finally, add the cross-linking agent Add the fly ash foam in proportion and stir for 3 to 5 minutes to obtain a high-stability colloidal foam.

Embodiment 2

[0036] A high-stability colloidal foam that inhibits the oxidation and self-heating of loose coal bodies is made of the following raw materials in weight percent: 63% water, 35% fly ash, 0.8% air-entraining agent, 0.6% film coating agent, cross-linked Agent 0.6%.

[0037] In this embodiment, the preparation method of the high-stability colloidal foam that inhibits the oxidative self-heating of loose coal bodies is the same as that in Embodiment 1.

Embodiment 3

[0039] A high-stability colloidal foam that inhibits the self-heating of loose coal oxidation, made of the following raw materials in weight percentage: 69% water, 30% fly ash, 0.5% air-entraining agent, 0.3% film coating agent, cross-linked Agent 0.2%.

[0040] In this embodiment, the preparation method of the high-stability colloidal foam that inhibits the oxidative self-heating of loose coal bodies is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com