Heat-insulating composite wear-resistant brick

A wear-resistant brick and unit technology, which is applied in the field of refractory brick production, can solve problems such as powdering and falling off of silicon-calcium board, increase of tertiary wind heat loss, and rise of cylinder surface temperature, and achieve good thermal shock stability and low thermal conductivity coefficient, the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

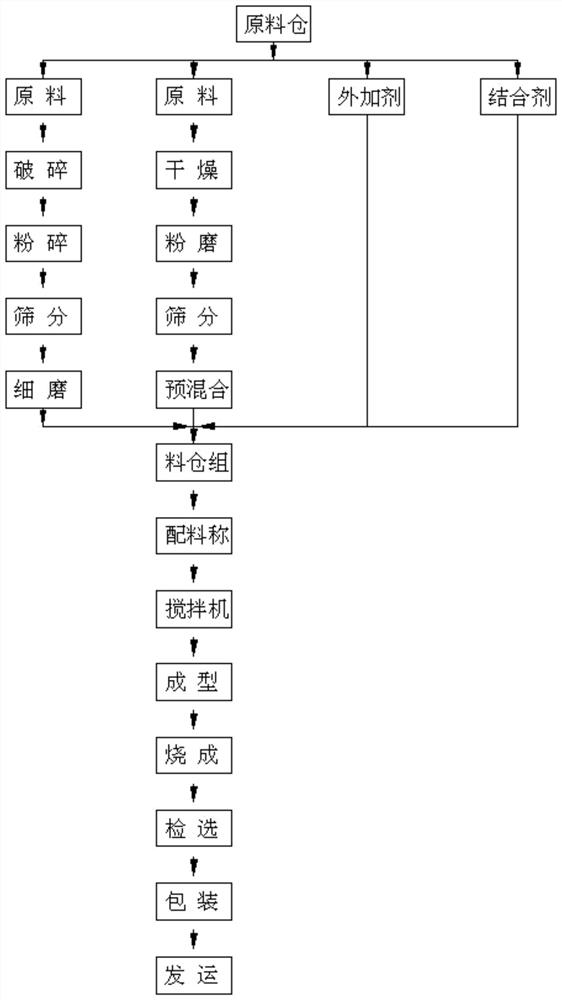

[0052] Provided in the present invention is a preparation method of a heat-insulating composite wear-resistant brick, and the preparation method is as follows:

[0053] 1), put the dried ceramsite and expanded vitrified microbeads into the ball mill in proportion to grind into 180 mesh fine powder, and put them into the warehouse for storage;

[0054] 2), put the magnesium-aluminum spinel, alumina hollow sphere, silicon carbide, the material made in step 1 into the mixer in proportion to stir, and the time is 10-15min;

[0055] 3), in the process of stirring in step 2, add admixture, binder and water reducing agent successively, and continue stirring, and the time is 30min, to prepare material;

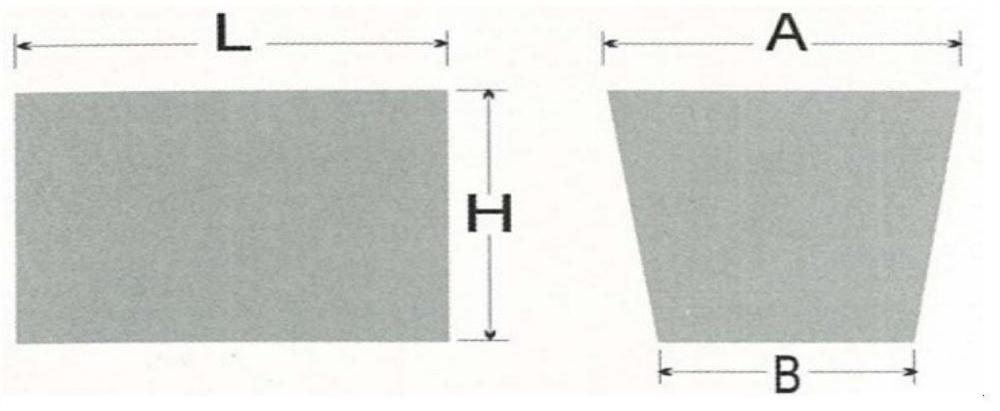

[0056] 4), the material in step 3 is shaped through a mold, and then put into a drying kiln for drying for 24-72h;

[0057] 5), put the model made in step 4 into a high-temperature kiln, sinter at a high temperature of ≧1500 ℃, calcinate for 72 hours, cool down after 72 hours, and ta...

Embodiment 2

[0059] For the production method of traditional high alumina refractory bricks:

[0060] 1. First put the raw high alumina bauxite into a high temperature kiln for calcination for 48 hours.

[0061] 2. The calcined high alumina bauxite is crushed and sieved into 5-3, 3-1, 1-0 graded aggregates. The sieved material enters the ball mill and is ground into 180 mesh fine powder, which is put into the silo for use. After drying, the clay raw material is ground into a 180-mesh fine powder in a ball mill for use.

[0062] 3. Take 70-80% high-alumina bauxite clinker and 20-30% high-alumina bauxite raw meal fine powder according to the weight percentage, put them in a mixer and stir evenly, then use a professional mold for pressing and molding, and then put them into drying It is dried in the kiln for 24-72 hours, and finally calcined in the high-temperature kiln for 72 hours.

[0063] Before 2010, my country's cement kiln production line was mainly based on 2500 tons of clinker / day...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com