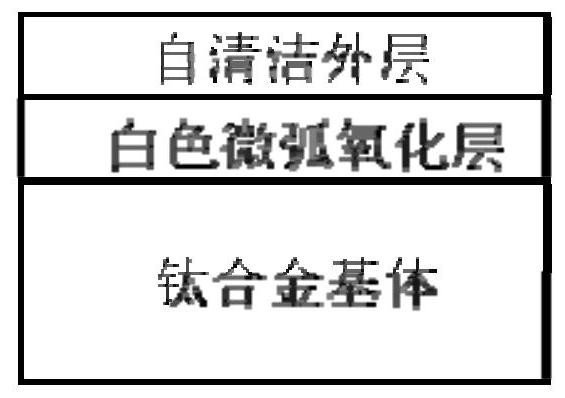

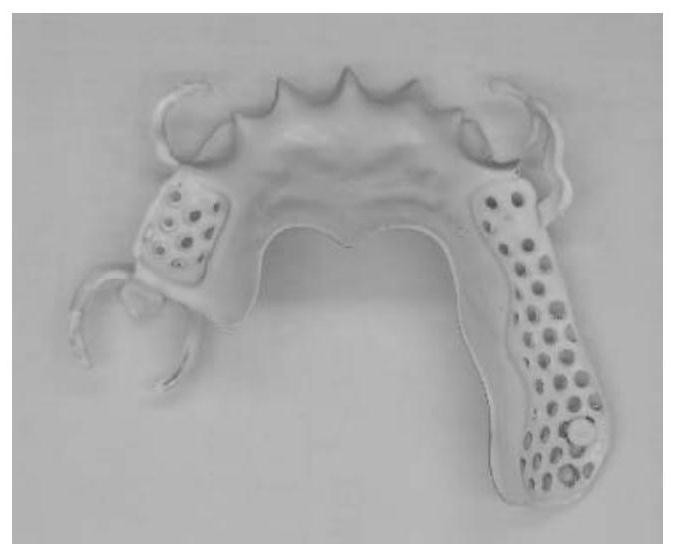

Whitening and self-cleaning coating of surface of titanium alloy dental prosthesis and preparation method of coating

A technology of self-cleaning coating and dental prosthesis, applied in the field of dental prosthetics, can solve problems such as poor wear resistance, low hardness, low density corrosion resistance, etc., and achieve simple and easy preparation process, good wear resistance and strong bonding force strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a whitening self-cleaning coating on the surface of a titanium alloy dental restoration and a preparation method thereof, the method comprising the following steps:

[0025] 1. Preparation of white micro-arc oxidation layer on the surface of titanium alloy dental restoration

[0026] (1) The components of the configured micro-arc oxidation electrolyte are: 50g / L sodium hydroxide, 15g / L sodium tripolyphosphate, dissolved in deionized water and stirred evenly to obtain the required micro-arc oxidation electrolyte;

[0027] (2) With pure titanium as the anode and the stainless steel container as the cathode, the micro-arc oxidation voltage is 75V, the frequency is 500 Hz, and the duty ratio is 30%. The micro-arc oxidation process is carried out, and the reaction time is 2 minutes to obtain a white micro-arc oxidation layer.

[0028] 2. Preparation of self-cleaning coating on the surface of micro-arc oxidation layer

[0029] (1) Perfluorooctyltrich...

Embodiment 2

[0033] This embodiment provides a whitening self-cleaning coating on the surface of a titanium alloy dental restoration and a preparation method thereof, the method comprising the following steps:

[0034] 1. Preparation of white micro-arc oxidation layer on the surface of titanium alloy dental restoration

[0035] (1) The components of the configured micro-arc oxidation electrolyte are: 60g / L sodium hydroxide, 10g / L sodium tripolyphosphate, dissolved in deionized water and stirred evenly to obtain the required micro-arc oxidation electrolyte;

[0036] (2) With pure titanium as the anode and the stainless steel container as the cathode, the micro-arc oxidation voltage is 70V, the frequency is 700Hz, and the duty ratio is 30%. The micro-arc oxidation process is carried out, and the reaction time is 5min to obtain a white micro-arc oxidation layer.

[0037] 2. Preparation of self-cleaning coating on the surface of micro-arc oxidation layer

[0038] (1) Configure a polytetrafluo...

Embodiment 3

[0042] This embodiment provides a whitening self-cleaning coating on the surface of a titanium alloy dental restoration and a preparation method thereof, the method comprising the following steps:

[0043] 1. Preparation of white micro-arc oxidation layer on the surface of titanium alloy dental restoration

[0044] (1) The components of the configured micro-arc oxidation electrolyte are: 40g / L sodium hydroxide, 15g / L sodium hexametaphosphate, dissolved in deionized water and stirred evenly to obtain the required micro-arc oxidation electrolyte;

[0045] (2) With pure titanium as the anode and the stainless steel container as the cathode, the micro-arc oxidation voltage is 80V, the frequency is 500Hz, and the duty cycle is 50%, the micro-arc oxidation process is carried out, and the reaction time is 2min to obtain a white micro-arc oxidation layer.

[0046] 2. Preparation of self-cleaning coating on the surface of micro-arc oxidation layer

[0047] (1) Perfluorooctyltrichloros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com