Preparation method of porous SiOC ceramic with composite pore structure

A technology of porous ceramics and composite pores, applied in the field of porous materials, can solve the problems of single pore-making method and difficulty in preparing porous ceramic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

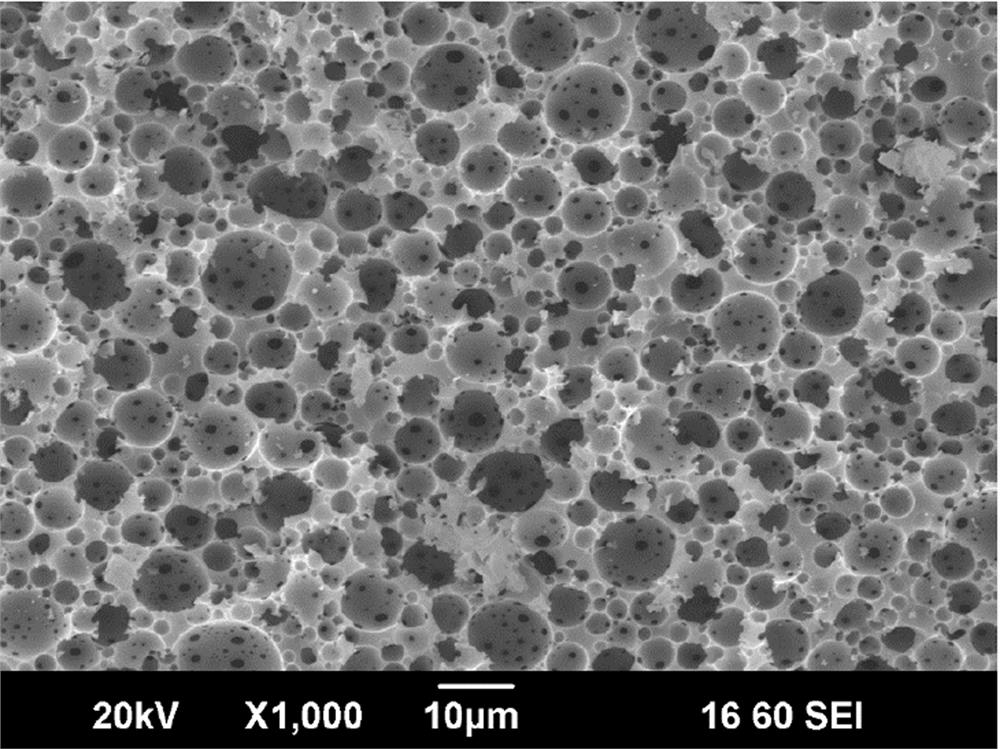

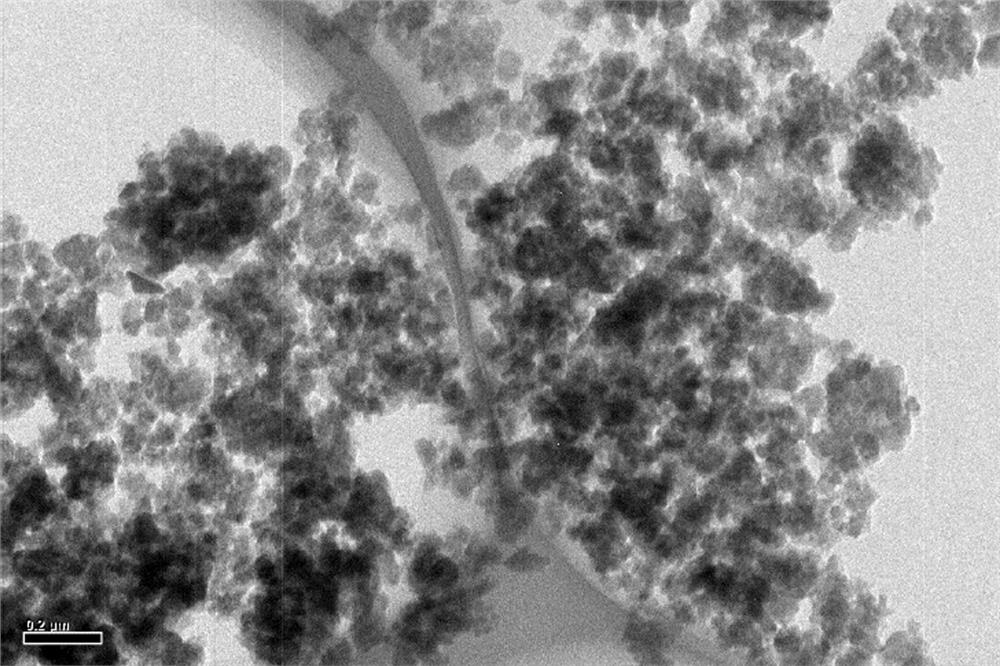

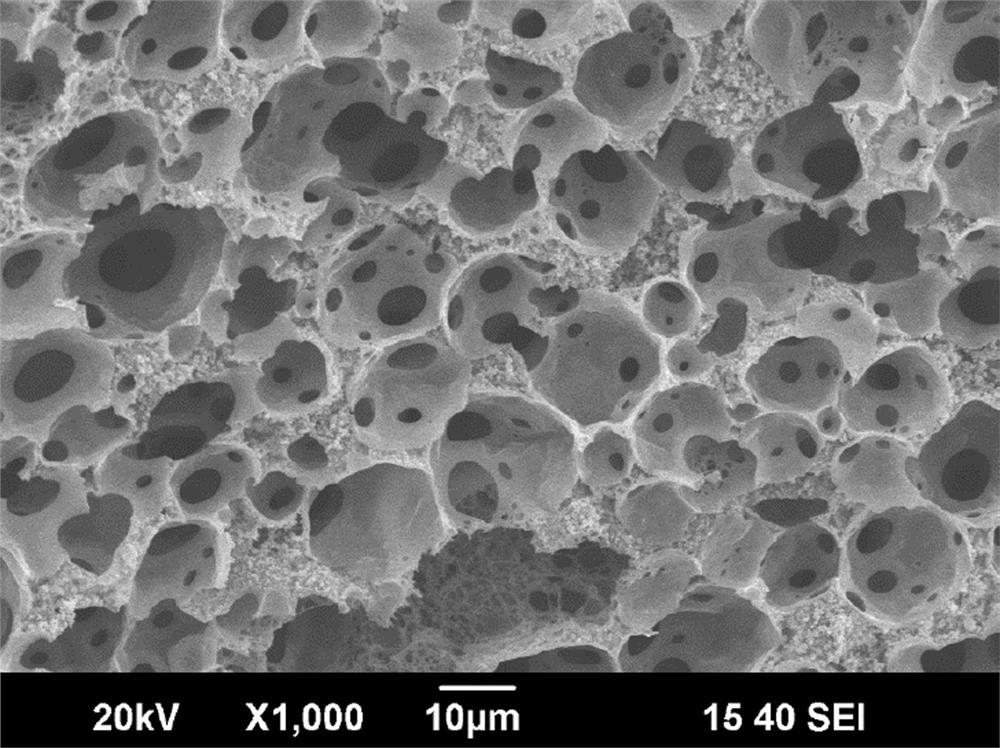

Image

Examples

Embodiment 1

[0032] Prepare the composite hole structure porous Sioc ceramics as follows:

[0033] (1) Oil phase formulation: Prevent the precursor liquid-containing polysiloxane and liquid porous polydimethylsiloxane and mix well for 10 min, then add catalyst dichloride palladium methane complex, stirred for 10 min, Finally, the emulsifier SPAN-80 was added, and the mixture was prepared for 10 min; wherein the mass ratio of the hydrogen-containing polysiloxane, polydimethylsiloxane and palladium palladium chloride complex is 1: 0.005; SPAN-80 quality is 20% of water quality.

[0034] (2) Oil-water mixing: The oil phase of step (1) is added to the oil phase during the stirring, and the mixture is stirred after 30 min after the dropwise addition is completed to obtain a stable and uniform oil-in-water type emulsion; wherein the oil phase and water The mass ratio is 1: 2, and the stirring speed is 500r / min.

[0035] (3) Curing: Pouring the oil-in-water emulsion of step (2) into the mold, placi...

Embodiment 2

[0039] Prepare the composite hole structure porous Sioc ceramics as follows:

[0040] (1) Oil phase formulation: Prevent the precursor liquid polymethylphenylsiloxane and liquid porcelane phenol resin is mixed 60 min, then add catalyst for dibutyltin, stirred for 20 min, and finally add emulsifier. Dimic acid dimethyl, stirred for 20 min to formulate oil phases; wherein the mass ratio of polymethylphenylsiloxane, phenolic resin and dibutyltin is 1: 3: 0.01; malonic acid dimethyl 5% of the water quality.

[0041] (2) Oil-water mixing: The oil phase of step (1) is added to the oil phase during the stirring, and the mixture is stirred after 30 min after the dropwise addition is completed to obtain a stable and uniform oil-in-water type emulsion; wherein the oil phase and water The mass ratio is 1: 1, and the stirring speed is 500r / min.

[0042] (3) Curing formation: Pouring the oil-in-water emulsion of step (2) into the mold, placing the mold in a constant temperature and humidity ...

Embodiment 3

[0045] Prepare the composite hole structure porous Sioc ceramics as follows:

[0046](1) Oil phase formulation: Prevent the precursor liquid-containing polysiloxane, tetramethyl-tetravinyl-ring silica oxide and liquid pore agent epoxy resin is mixed 50 min, then add catalyst platinum two Vinyl tetramethyl-di siloxane complex, stirred for 10 min, finally added modified silicone oil of the emulsifier containing polyoxyethylene group, stirred for 10 min to formulate oil; wherein hydrogen-containing polysiloxane, four Methyl-tetravathor-cyclosiloxane, epoxy resin, platinum diethylene tetramethyl - silicone complex mass ratio is 1: 1: 8: 0.03; containing polyoxyethylene group Modified organic silicone oil quality is 2% of water quality.

[0047] (2) Oil-water mixing: The oil phase of step (1) is added to the oil phase during the stirring, and the mixture is stirred after 30 min after the dropwise addition is completed to obtain a stable and uniform oil-in-water type emulsion; wherein t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com