Tin-doped two-dimensional molybdenum sulfide, preparation method and application thereof

A technology of molybdenum sulfide and molybdenum sources, applied in chemical instruments and methods, from chemically reactive gases, nanotechnology for materials and surface science, etc., can solve the application limitations of two-dimensional transition metal dichalcogenide materials, charge Problems such as the deviation of the ability to absorb photons in the mobility and the inability to realize the preparation of doped two-dimensional materials have achieved the effects of improved photodetection performance, stable and controllable growth conditions, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

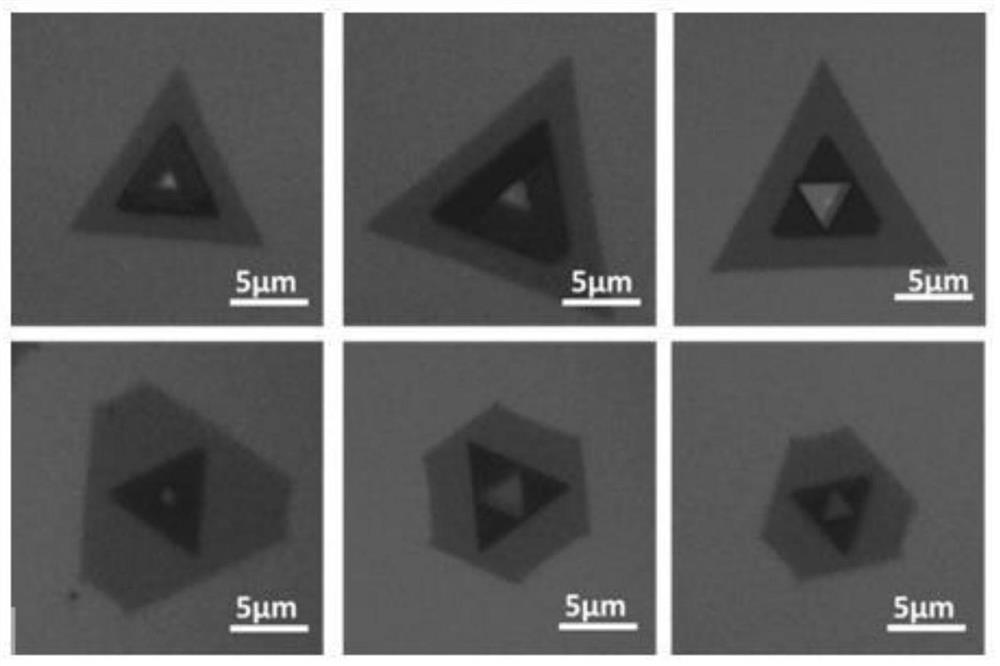

[0042] The invention provides a method for preparing tin-doped two-dimensional molybdenum sulfide, the preparation method comprising the following steps:

[0043] 1) Preparation of the insulating substrate: ultrasonically treat the insulating substrate in different organic solvents, and dry it with nitrogen after cleaning;

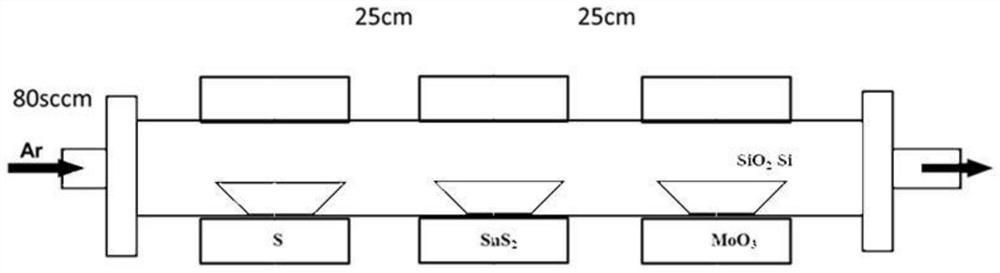

[0044] 2) Preparation of reactants: Weigh the precursor molybdenum source, tin source and sulfur source, place the precursor molybdenum source, tin source and sulfur source in three independent reaction vessel quartz boats respectively, and place the The insulating substrate is buckled upside down on the quartz boat of the reaction vessel carrying the molybdenum source;

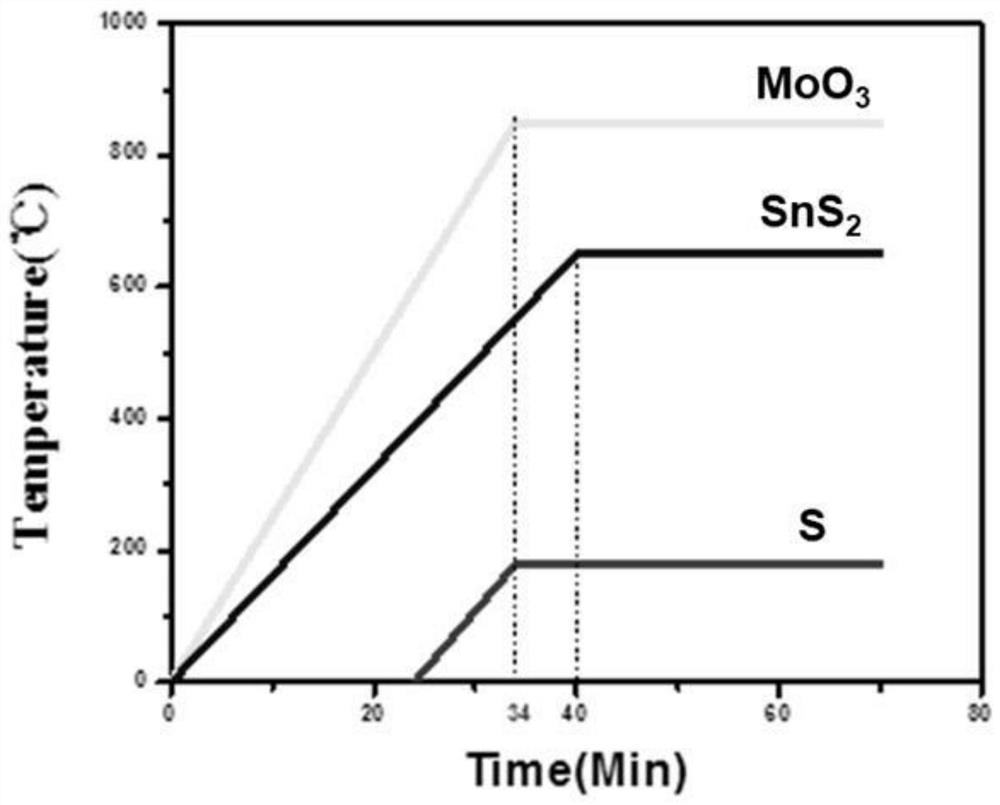

[0045] 3) Reaction temperature setting: Different temperature zones of the reaction furnace are set according to different heating rates, heating phases, constant temperature phases and cooling phase time;

[0046] 4) Generation of the product: First, put the three reaction vessels obtai...

Embodiment 1

[0051] This embodiment discloses a method for preparing tin-doped two-dimensional molybdenum sulfide under normal pressure, which includes the following steps:

[0052] 1) Preparation of insulating silicon wafer substrate: put the cut insulating silicon wafer into acetone and isopropanol for ultrasonic treatment, and finally wash with deionized water and blow dry with nitrogen;

[0053] 2) Weighing of reactants: Use an electronic balance to weigh the precursor molybdenum trioxide (MoO 3 ) 10mg, tin disulfide (SnS 2 ) 200mg and sulfur powder (S) 100mg, then the reactants were placed in three independent quartz boats, and finally the clean insulating silicon wafer after step 1) was processed upside down on the quartz boat carrying molybdenum oxide;

[0054] 3) Setting of the reaction temperature: Each temperature zone of the three-temperature zone tube furnace is set according to different heating rates and the time of the heating stage, constant temperature stage and cooling s...

Embodiment 2

[0057] This embodiment discloses a method for preparing tin-doped two-dimensional molybdenum sulfide under normal pressure, which includes the following steps:

[0058] 1) Preparation of insulating silicon wafer substrate: put the cut insulating silicon wafer into acetone and isopropanol for ultrasonic treatment, and finally wash with deionized water and blow dry with nitrogen;

[0059] 2) Weighing of reactants: Use an electronic balance to weigh the precursor molybdenum trioxide (MoO 3 ) 10mg, tin tetrachloride (SnCl 4 ) 220mg and sulfur powder (S) 80mg, then the reactants were placed in three independent quartz boats, and finally the clean insulating silicon wafer after step 1) was processed upside down on the quartz boat carrying molybdenum oxide;

[0060] 3) Setting of the reaction temperature: each temperature zone of the three-temperature zone tube furnace is set according to different heating rates and the time of the heating stage, constant temperature stage and cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com