Biomass functional master batch as well as preparation method and application thereof

A functional masterbatch and biomass technology, which is applied in the field of biomass functional masterbatch and its preparation, can solve the problem of unsatisfactory dispersion and plasticization effects of biomass powder fillers, which affect the popularization and promotion of fully biodegradable films, Improve the cost of products in downstream blown film factories, etc., to achieve the effect of improving the flexibility of blown film production, excellent blow molding processing performance, and reducing application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

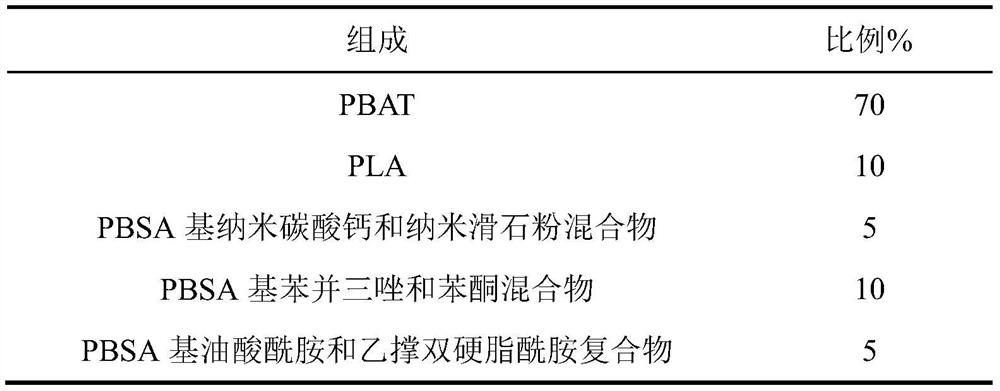

Examples

preparation example Construction

[0052] The second aspect of the present invention provides a method for preparing the biomass functional masterbatch as described above, comprising:

[0053] The biodegradable polymer and functional components are mixed and granulated at 80-180°C. When the functional component is biomass powder or inorganic filler, mix and granulate at 120-180°C; when the functional component is an auxiliary agent, mix and granulate at 80-120°C. Mixing and granulation can be carried out by means of extrusion, hot pressing or banburying, such as through a 65D or 75A extruder whose aspect ratio is 40:1, 56:1 or 60:1, preferably 56:1 or In hot-press granulation equipment, internal mixer, etc., biomass resin is prepared by extrusion or pressing at a certain processing temperature. Such as a variety of film materials, such as winding functional film, agricultural mulch film, plastic bag film, disposable glove film, etc., to meet various application requirements.

[0054] The third aspect of the p...

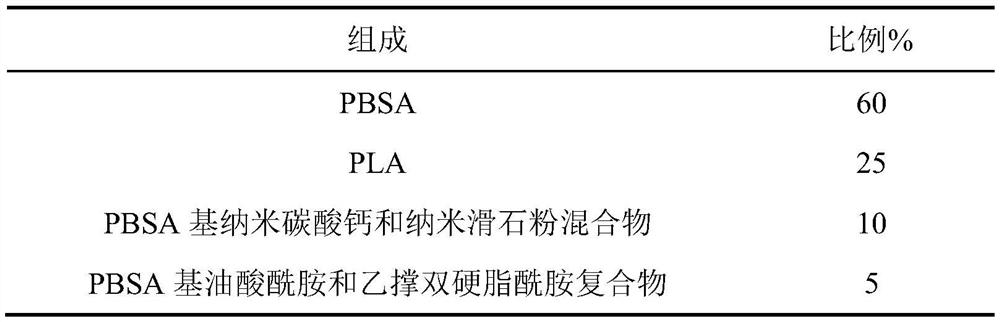

Embodiment 1

[0062] This example provides a kind of PBSA-based nano-calcium carbonate and nano-talcum powder mixture, nano-calcium carbonate and nano-talc powder account for 90wt% of the PBSA-based nano-calcium carbonate and nano-talcum powder mixture, the weight ratio of the nano-calcium carbonate and nano-talc powder 1:1.

[0063] This example also provides a method for preparing a mixture of PBSA-based nano-calcium carbonate and nano-talc powder, comprising: mixing and granulating PBSA, nano-calcium carbonate and nano-talc powder at 160°C.

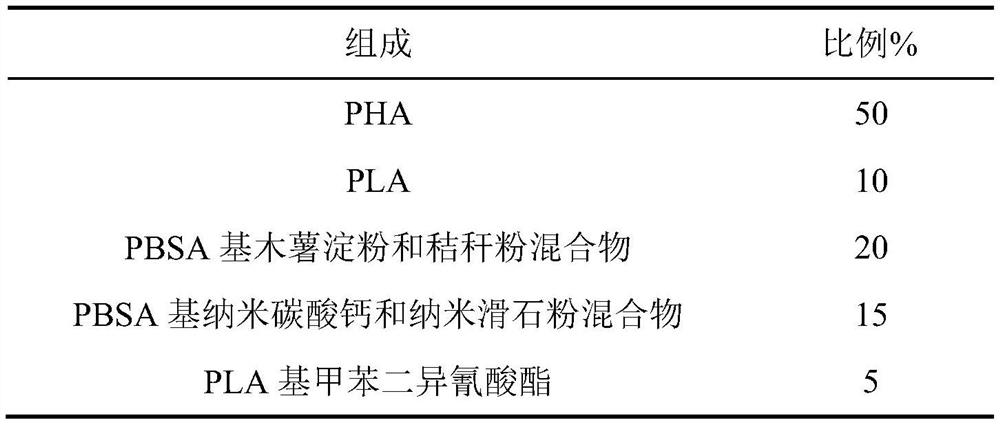

Embodiment 2

[0065] This example provides a mixture of PBSA-based tapioca starch and straw powder, where the tapioca starch and straw powder account for 85 wt% of the mixture of PBSA-based tapioca starch and straw powder, and the weight ratio of the tapioca starch and straw powder is 2:1.

[0066] This example also provides a method for preparing a mixture of PBSA-based tapioca starch and straw powder, comprising: mixing and granulating PBSA, tapioca starch and straw powder at 140°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com