Preparation method of high-strength environment-friendly wood plywood

A kind of wood plywood, high-strength technology, applied in the joint of wooden veneers, other plywood/plywood appliances, adhesives, etc., can solve the problems of unguaranteed mechanical properties and hazards of wood plywood, and achieve easy tight and firm combination, Effects of cost reduction and usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

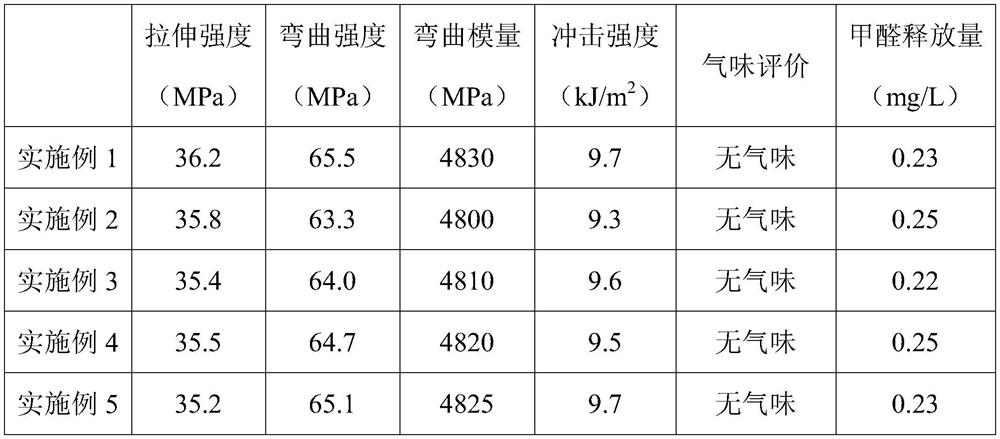

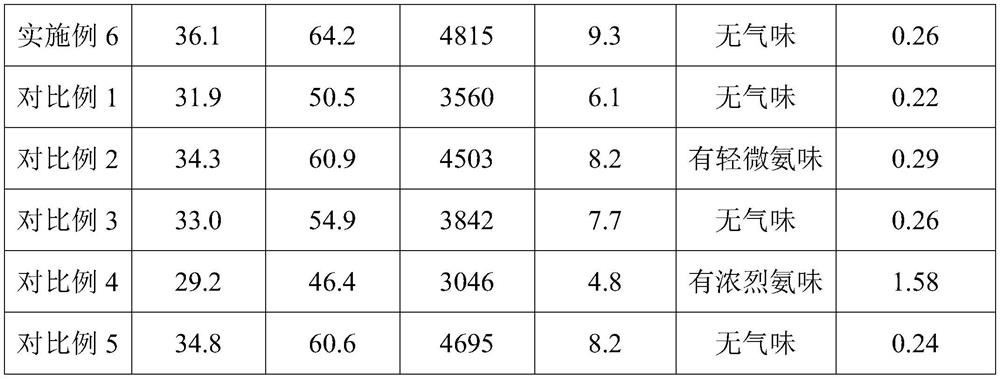

Examples

Embodiment 1

[0026] A kind of preparation method of high-strength environment-friendly plywood:

[0027] Mix isophorone diisocyanate, polycarbonate diol, epoxy resin, and dibutyltin dilaurate evenly, then heat up to 70°C, react for 2 hours, and mix 2,2-dimethylolpropionic acid and 1,4- The composite chain extender composed of butanediol in a mass ratio of 1:1 was dissolved in acetone and added to the reaction system, continued to react for 5 hours, cooled to 40°C, added hydroxyethyl acrylate and continued to react for 2 hours, and then added tetraethyl ammonium hydroxide, add water after stirring for 10 minutes, and finally disperse at a high speed for 1 hour to obtain a water-based polyurethane emulsion. Add gelatinized starch to a sodium hypochlorite solution with a mass concentration of 10%, heat up to 90°C for 3 hours, filter, wash and dry to obtain oxidized After the gelatinized starch, mix it with polyvinyl alcohol, potassium persulfate, water, heat up to 65 ° C, stir for 5 hours, co...

Embodiment 2

[0029] A kind of preparation method of high-strength environment-friendly plywood:

[0030]Mix isophorone diisocyanate, polycarbonate diol, epoxy resin, and dibutyltin dilaurate evenly, then heat up to 60°C, react for 1 hour, and mix 2,2-dimethylolpropionic acid and 1,4- The composite chain extender composed of butanediol in a mass ratio of 1:1 is dissolved in acetone and added to the reaction system, and the reaction is continued for 3 hours, the temperature is lowered to 40°C, the end-capping agent hydroxyethyl acrylate is added to continue the reaction for 1 hour, and then tetraethyl ammonium hydroxide, add water after stirring for 5 minutes, and finally disperse at high speed for 1 hour to obtain water-based polyurethane emulsion. After the gelatinized starch, mix it with polyvinyl alcohol, potassium persulfate, water, heat up to 60 ° C, stir for 5 hours, cool down to 40 ° C and add chitosan and mannitol, the oxidized gelatinized starch, poly The mass ratio of vinyl alcoh...

Embodiment 3

[0032] A kind of preparation method of high-strength environment-friendly plywood:

[0033] Mix isophorone diisocyanate, polycarbonate diol, epoxy resin, and dibutyltin dilaurate evenly, then heat up to 75°C, react for 2 hours, and mix 2,2-dimethylolpropionic acid and 1,4- The composite chain extender composed of butanediol in a mass ratio of 1:1 was dissolved in acetone and added to the reaction system, continued to react for 5 hours, cooled to 45°C, added end-capping agent hydroxyethyl acrylate and continued to react for 2 hours, and then added tetraethyl ammonium hydroxide, add water after stirring for 10 minutes, and finally disperse at high speed for 2 hours to obtain water-based polyurethane emulsion. The final gelatinized starch was mixed with polyvinyl alcohol, potassium persulfate, and water, heated to 70°C, stirred for 10 hours, cooled to 50°C, chitosan and mannitol were added, and the oxidized gelatinized starch, poly The mass ratio of vinyl alcohol and chitosan is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com