Preparation method of diamond-ceramic composite material based on photocuring molding

A ceramic composite material and light-curing molding technology, which is applied in the direction of diamond and additive processing, can solve the problems of reducing the mechanical properties of materials, affecting the curing and forming effect, and prone to graphitization, so as to reduce graphitization and improve curing molding effect, the effect of lowering the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A kind of preparation method based on the diamond-ceramic composite material of photocuring molding, it is characterized in that, comprises the following steps:

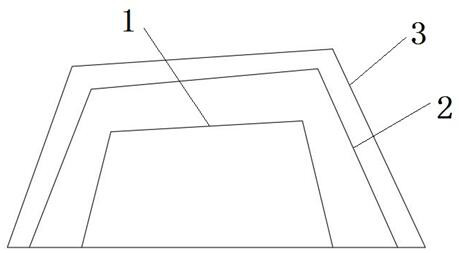

[0039] Weighing diamond powder and titanium powder, through the molten salt method, realizes titanium coating on the surface of diamond 1, and obtains diamond titanium coating layer 2;

[0040] Coating paraffin on the surface of the diamond after titanium plating by ball milling to obtain a paraffin layer 3;

[0041] Weighing the secondary coated diamond particles and glass phase ceramic powder and mixing them uniformly in a ball mill, then drying in an oven, taking them out and sieving to obtain a diamond-glass phase ceramic mixed powder;

[0042] Put the obtained mixed powder, photocurable resin and dispersant into a homogenizer, and mix evenly to obtain a photocurable diamond-ceramic composite material slurry;

[0043] Then through the DLP printing in the additive manufacturing technology; and then through...

Embodiment 1

[0045] This embodiment provides a method for preparing a diamond-ceramic composite material based on photocuring, comprising the following steps:

[0046]Weigh diamond powder and titanium powder, and through the molten salt method, the diamond surface is coated with titanium; the surface of diamond after titanium coating is coated with paraffin wax by ball milling method; the diamond particles and glass phase ceramic powder after secondary coating are weighed in a ball mill Mix evenly in an oven, then dry in an oven, take it out and sieve to obtain a diamond-glass phase ceramic mixed powder; put the obtained mixed powder, photocurable resin and dispersant into a homogenizer, and mix evenly , to obtain light-cured diamond-ceramic composite slurry; then through DLP printing in additive manufacturing technology; and then through vacuum hot-pressing sintering, to obtain light-cured DLP printing diamond-glass phase ceramic composite parts. Among them, the diamond after the secondar...

Embodiment 2

[0063] This embodiment provides a method for preparing a diamond-ceramic composite material based on photocuring, comprising the following steps:

[0064] Weigh diamond powder and titanium powder, and through the molten salt method, the diamond surface is coated with titanium; the surface of diamond after titanium coating is coated with paraffin wax by ball milling method; the diamond particles and glass phase ceramic powder after secondary coating are weighed in a ball mill Mix evenly in an oven, then dry in an oven, take it out and sieve to obtain a diamond-glass phase ceramic mixed powder; put the obtained mixed powder, photocurable resin and dispersant into a homogenizer, and mix evenly , to obtain light-cured diamond-ceramic composite slurry; then through DLP printing in additive manufacturing technology; and then through vacuum hot-pressing sintering, to obtain light-cured DLP printing diamond-glass phase ceramic composite parts. Among them, the diamond after the seconda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com