Wine box stamping and punching production line and production process

A production line and wine box technology, applied in box production operations, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of increased production efficiency, production costs, inability to complete assembly line production, and excessive labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

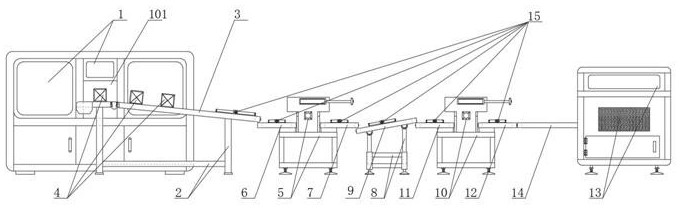

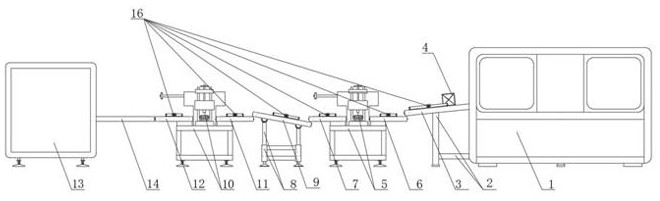

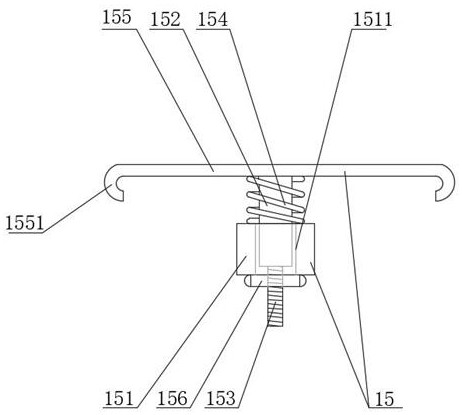

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] refer to Figure 1-4 , a wine box punching and punching production line described in this specific embodiment, including a wine box forming machine 1, a discharge port 101, a support frame A2, a conveyor A3, a wine box 4, a wine box punching and punching machine A5, a conveying Machine B6, conveyor C7, support frame A8, conveyor D9, wine box stamping and punching machine B10, conveyor E11, conveyor F12, wine box five-sided bubble pressing machine 13, conveyor G14, limit assembly A15 and limit Bit assembly B16, the middle part of the front side wall of the wine box forming machine 1 is provided with a discharge port 101, the front side of the wine box forming machine 1 is provided with a supporting frame A2, and the upper end of the supporting frame A2 is fixedly equipped with a conveyor A3, and the conveying The rear side wall of the machine A3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com