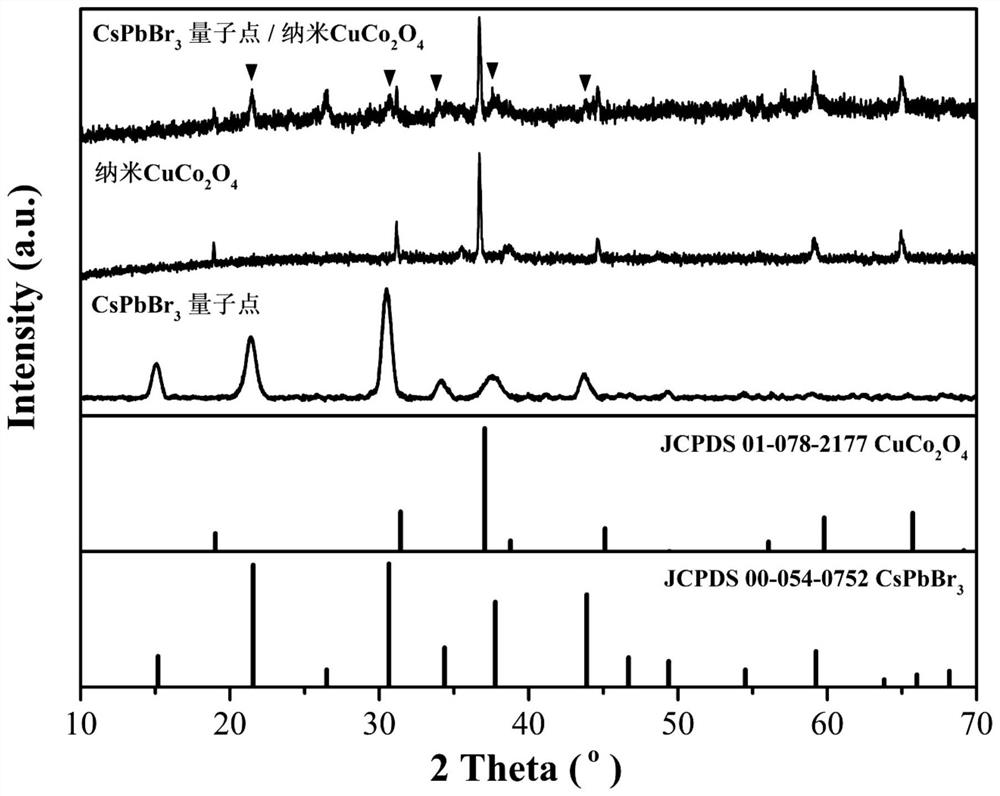

CsPbBr3 quantum dot/nano CuCo2O4 composite photocatalyst for CO2 reduction and preparation method of CsPbBr3 quantum dot/nano CuCo2O4 composite photocatalyst

A technology of quantum dots and composite light, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve the problem of high photocatalytic reaction rate and visible light band light absorption performance , cost increase, application scene limitations and other issues, to achieve the effect of excellent visible light absorption performance, low cost, and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

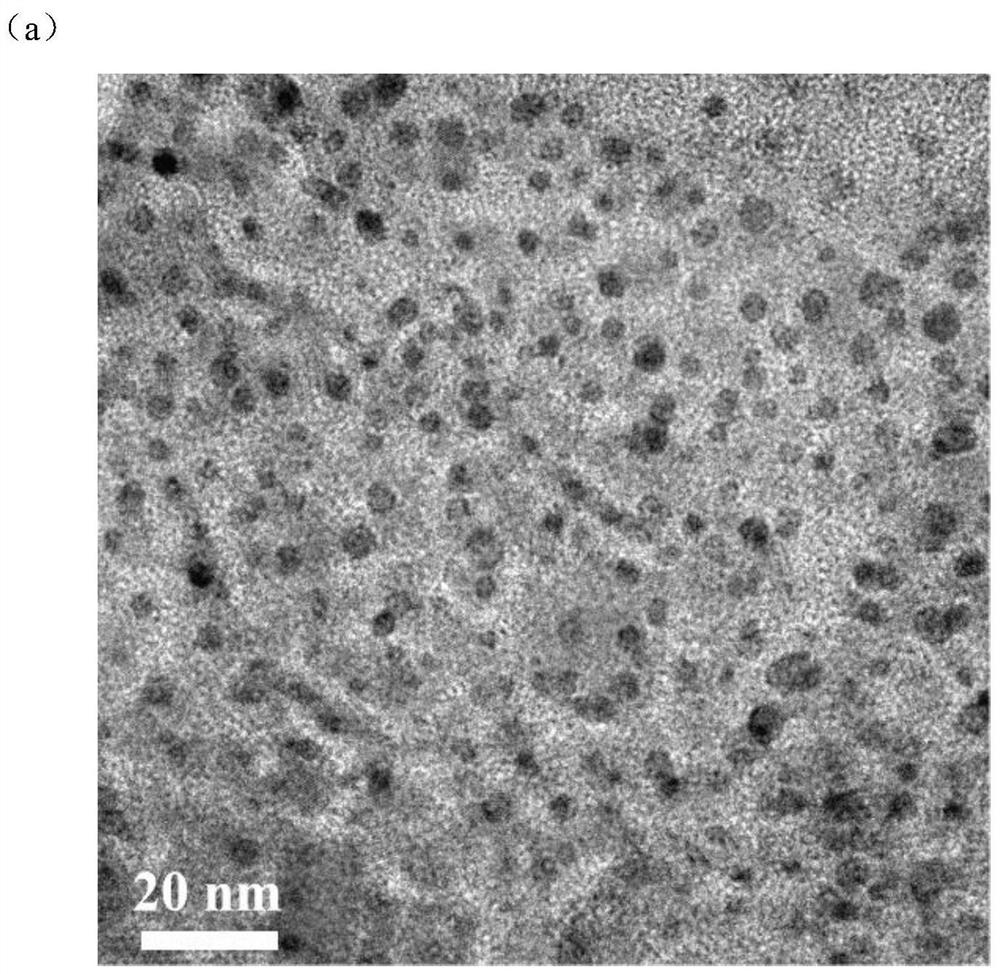

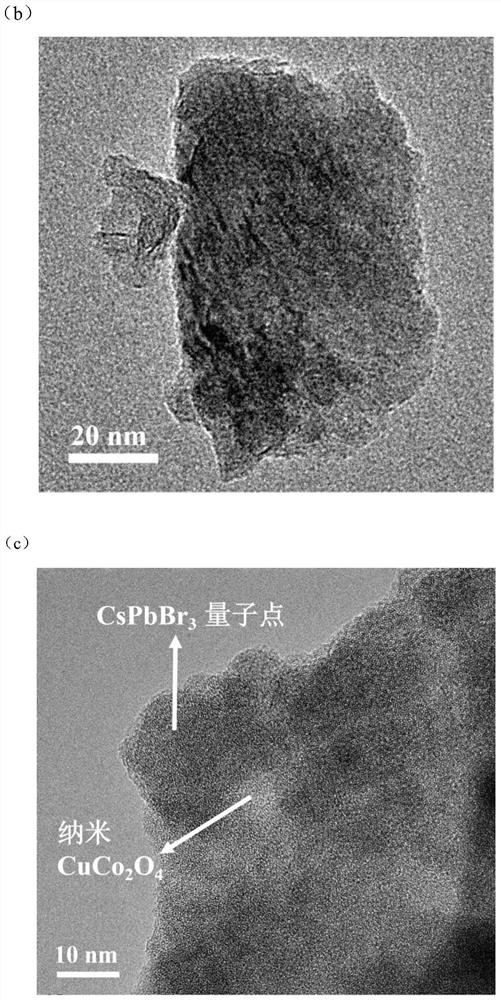

Method used

Image

Examples

Embodiment 1

[0034] Nano CuCo 2 o 4 The preparation method comprises the following steps:

[0035] (A1) 1mmol of Cu(NO 3 ) 2 .6H 2 O, 2mmol of Co(NO 3 ) 2 .6H 2 O, 5mmol of CH 4 N 2 O and 2 mmol of NH 4 F was dissolved in 30-60mL of ethanol, stirred at room temperature for 60min, stirred evenly and fully mixed, then transferred to a 100mL tetrafluoroethylene-lined stainless steel autoclave, placed in a vacuum drying oven, the drying temperature was 200°C, and the drying time was for 12h;

[0036] (A2) After washing the product obtained in step (A1) alternately with distilled water and ethanol for multiple times, place it in an oven for drying, the drying temperature is 80° C., and the drying time is 8 hours;

[0037] (A3) Calcining the product obtained in step (A2), the calcination temperature is 400°C, the calcination time is 2h, the heating rate of calcination is 5°C / min, and after cooling to room temperature, grind it in a mortar for 30min , and then add 2mL n-hexane to ultr...

Embodiment 2

[0046] Nano CuCo 2 o 4 The preparation method comprises the following steps:

[0047] (A1) 0.5mmol of Cu(NO 3 ) 2 .6H 2 O, 1mmol of Co(NO 3 ) 2 .6H 2 O, 2.5 mmol of CH 4 N 2 O and 1 mmol of NH 4 F was dissolved in 50mL of ethanol, stirred at room temperature for 30min, stirred evenly and fully mixed, then transferred to a 100mL tetrafluoroethylene-lined stainless steel autoclave, placed in a vacuum drying oven, the drying temperature was 180°C, and the drying time was 16h;

[0048] (A2) After washing the product obtained in step (A1) alternately with distilled water and ethanol several times, place it in an oven and dry it at a temperature of 100° C. for 10 hours;

[0049] (A3) Calcining the product obtained in step (A2), the calcination temperature is 450°C, the calcination time is 3h, the heating rate of the calcination is 4°C / min, after cooling to room temperature, grind it in a mortar, and the grinding time is 60min , and then add 10mL of n-hexane for ultrasonic...

Embodiment 3

[0058] Nano CuCo 2 o 4 The preparation method comprises the following steps:

[0059] (A1) 0.2mmol of Cu(NO 3 ) 2 .6H 2 O, 0.4mmol of Co(NO 3 ) 2 .6H 2 O, 1 mmol of CH 4 N 2 O and 0.4 mmol of NH 4 F was dissolved in 40mL of ethanol, stirred at room temperature for 20min, stirred evenly and fully mixed, then transferred to a 100mL tetrafluoroethylene-lined stainless steel autoclave, placed in a vacuum drying oven, the drying temperature was 160°C, and the drying time was 10h;

[0060] (A2) After washing the product obtained in step (A1) alternately with distilled water and ethanol several times, place it in an oven for drying at a drying temperature of 80° C. for 12 hours;

[0061] (A3) Calcining the product obtained in step (A2), the calcination temperature is 300°C, the calcination time is 4h, the heating rate of calcination is 3°C / min, and after cooling to room temperature, grind it in a mortar, and the grinding time is 20min , and then add 5mL n-hexane for ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com