Surface-coated modified porous calcium phosphate ceramic microspheres and preparation method and application thereof

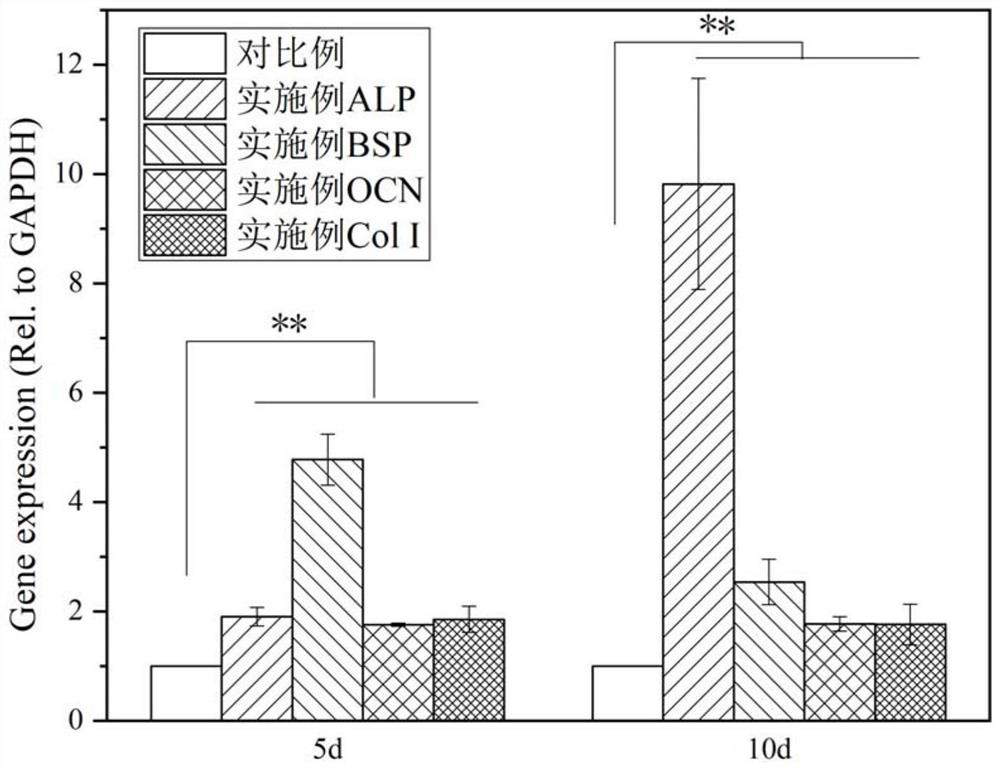

A technology of porous calcium phosphate and surface coating, applied in the field of medical materials for bone injury repair, can solve the problems of low production efficiency, inconvenience, difficult to control the diameter of the ball and its distribution, etc., to improve expression, improve osteogenic differentiation and/or Angiogenesis ability, the effect of promoting tubulogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Uniformly mix β-tricalcium phosphate powder, microcrystalline cellulose and polystyrene microsphere pore-forming agent with a median diameter of about 40 μm to obtain a solid phase mixture. The mass fraction of microcrystalline cellulose is 30%, and the volume ratio of pore-forming agent to beta-tricalcium phosphate powder is 1.5:1. A 0.5% methyl cellulose aqueous solution is prepared and slowly added to the solid phase mixture, and a plastic wet material is obtained after uniform mixing, wherein the mass fraction of the binder is 40%.

[0028] 2) Load the plastic wet material obtained in step 1) into the extrusion device of the extrusion spheronizer, and extrude it from an orifice plate with a diameter of 1.5 mm to obtain a bar-shaped cylindrical material; pour the bar-shaped cylindrical material into a spheronizing device, and rolling to obtain microspheres.

[0029] 3) adding magnesium phosphate powder to the microspheres of the spheronizing device in step 2) to ...

Embodiment 2

[0033] 1) Uniformly mix β-tricalcium phosphate powder, microcrystalline cellulose and polystyrene microsphere pore-forming agent with a median diameter of about 40 μm to obtain a solid phase mixture. The mass fraction of microcrystalline cellulose is 30%, and the volume ratio of pore-forming agent to beta-tricalcium phosphate powder is 1.5:1. A 0.5% methyl cellulose aqueous solution is prepared and slowly added to the solid phase mixture, and a plastic wet material is obtained after uniform mixing, wherein the mass fraction of the binder is 40%.

[0034] 2) Load the plastic wet material obtained in step 1) into the extrusion device of the extrusion spheronizer, and extrude it from an orifice plate with a diameter of 1.5 mm to obtain a bar-shaped cylindrical material; pour the bar-shaped cylindrical material into into a spheronizing device, and rolling to obtain microspheres.

[0035] 3) The magnesium phosphate powder is added to the microspheres of the spheronizing device in ...

Embodiment 3

[0039] 1) uniformly mixing hydroxyapatite powder, microcrystalline cellulose and paraffin microsphere pore-forming agent with a median diameter of about 100 μm to obtain a solid phase mixture. The mass fraction of microcrystalline cellulose is 20%, and the volume ratio of pore-forming agent to hydroxyapatite powder is 2:1. A 0.5% methyl cellulose aqueous solution is prepared and slowly added to the solid phase mixture, and a plastic wet material is obtained after uniform mixing, wherein the mass fraction of the binder is 30%.

[0040] 2) Load the plastic wet material obtained in step 1) into the extrusion device of the extrusion spheronizer, and extrude it from an orifice plate with a diameter of 1.5 mm to obtain a bar-shaped cylindrical material; pour the bar-shaped cylindrical material into a spheronizing device, and rolling to obtain microspheres.

[0041] 3) adding the strontium silicate powder to the microspheres of the spheronizing device in step 2) to obtain microspher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com