Heat-conducting composite material as well as preparation method and application thereof

A technology of heat-conducting composite materials and composites, which is applied in the direction of heat exchange materials, chemical instruments and methods, semiconductor devices, etc., and can solve the problems of inability to meet high heat accumulation, inability to meet heat conduction requirements, and low thermal conductivity between surfaces , to achieve the effect of overcoming thermal anisotropy, good thermal conductivity, and improving thermal conductivity between surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

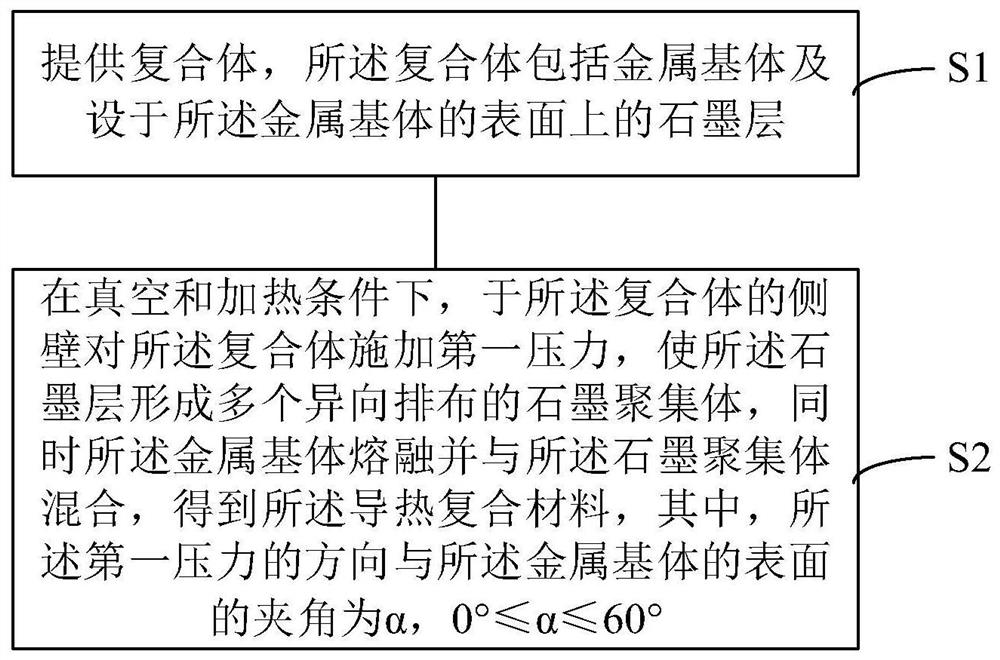

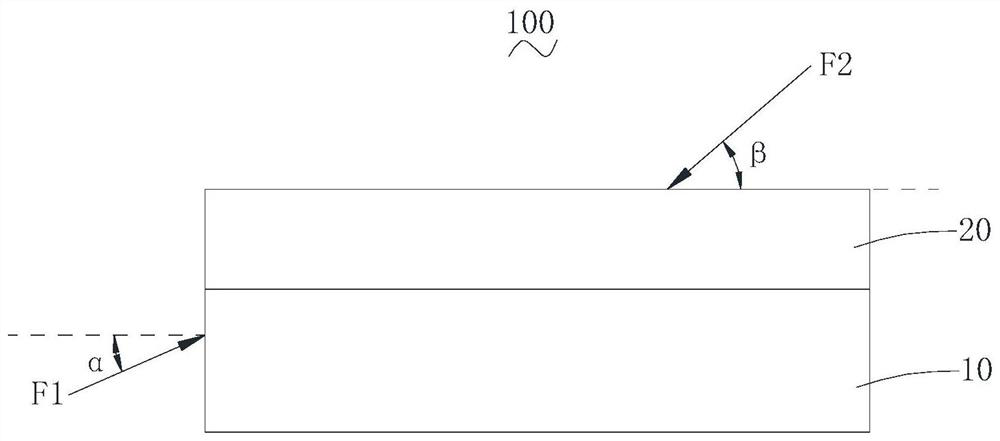

[0033] see Figure 1 to Figure 3 , the preparation method of the thermally conductive composite material, comprising the following steps:

[0034] S1: providing a composite body 100, the composite body 100 comprising a metal substrate 10 and a graphite layer 20 disposed on the surface of the metal substrate 10;

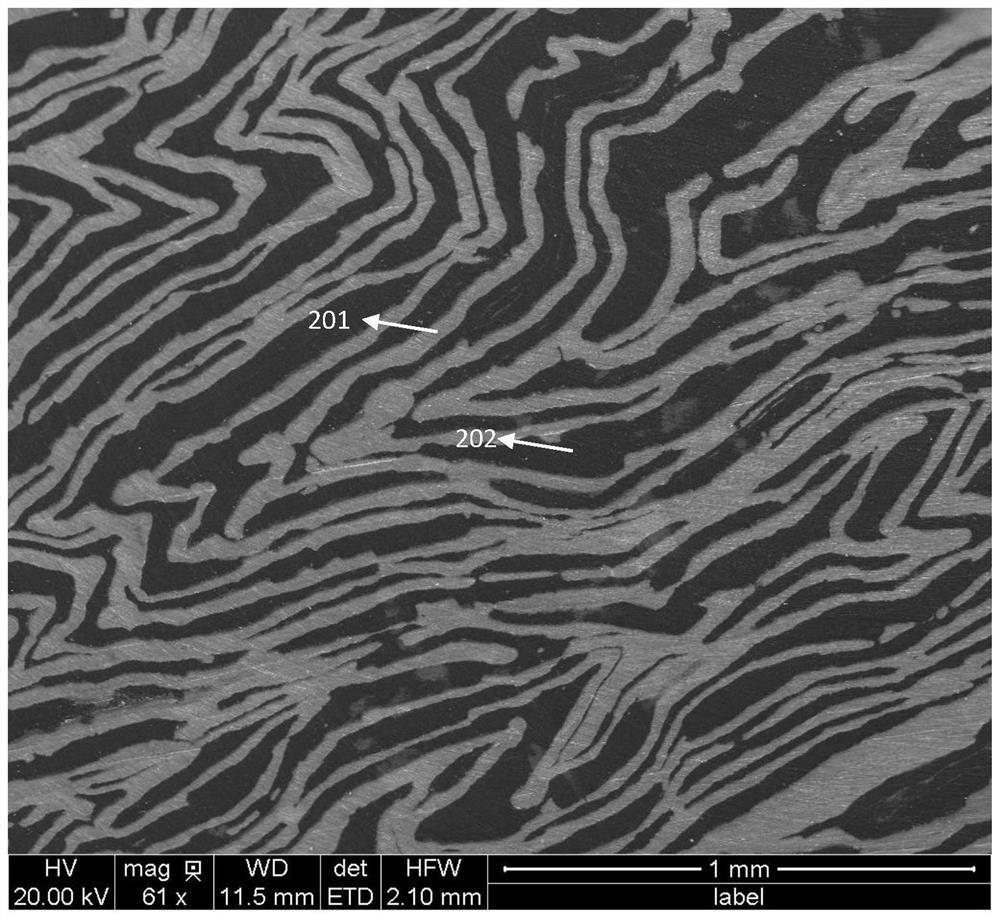

[0035] S2: Under vacuum and heating conditions, apply a first pressure F1 to the composite body 100 on the side wall of the composite body 100, so that the graphite layer 20 forms a plurality of graphite aggregates 202 arranged anisotropically, and at the same time The metal matrix 10 is melted and mixed with the graphite aggregate 202 to obtain the thermally conductive composite material, wherein the angle between the direction of the first pressure F1 and the direction of the surface of the metal matrix 10 is α, 0 °≤α≤60°.

[0036] In step S1, the material of the metal base 10 includes at least one of copper, aluminum, and silver, and the material of the graphite ...

Embodiment 1

[0071] Take a 60 μm thick aluminum foil, and spray atomized glue on the surface of the aluminum foil. Then pour the spherical graphite powder onto the atomized rubber layer, and blow off the excess graphite powder with a blower to form a graphite layer with a thickness of 40 μm, and the mass ratio of the graphite layer to the aluminum foil is 50:50 to obtain a graphite-aluminum composite . Put the graphite-aluminum composite body vertically into a hot-pressing mold and sinter in a vacuum one-way hot-pressing sintering furnace, and heat the temperature in the sintering furnace to 650°C at a heating rate of 10°C / min for sintering. for 60 minutes, the first pressure is 40 MPa, and the angle α between the direction of the first pressure and the direction of the surface of the metal substrate is 0°, and then cooled to room temperature with the furnace to prepare a thermally conductive composite material.

Embodiment 2

[0073] Take a copper foil with a thickness of 100 μm, and spray atomized glue on the surface of the copper foil. Then pour the flake graphite powder onto the atomized glue layer, and blow off the excess graphite powder with a blower to form a graphite layer with a thickness of 20 μm, and the mass ratio of flake graphite to copper foil is 40:60. Then, the flake graphite is subjected to rolling treatment, the rolling pressure is 0.5 MPa, and the rolling time is 1 minute, to form a graphite-copper composite.

[0074] Put the graphite-copper composite vertically into a hot-pressing mold and sinter in a vacuum one-way hot-pressing sintering furnace. Heat the temperature in the sintering furnace to 1000°C at a heating rate of 20°C / min for sintering. The holding time is for 60 minutes, the first pressure is 10 MPa, and the angle α between the direction of the first pressure and the direction of the surface of the metal substrate is 5°, and then cooled to room temperature with the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com