Welding method of high-bonding-strength copper-steel bimetallic antifriction wear-resistant composite material

A technology combining strength and composite materials, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve problems such as increasing industrial costs, relative weight segregation of lead lubrication, and unfavorable enterprise production and manufacturing, to reduce economic costs, reduce Soldering temperature, the effect of avoiding shrinkage and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

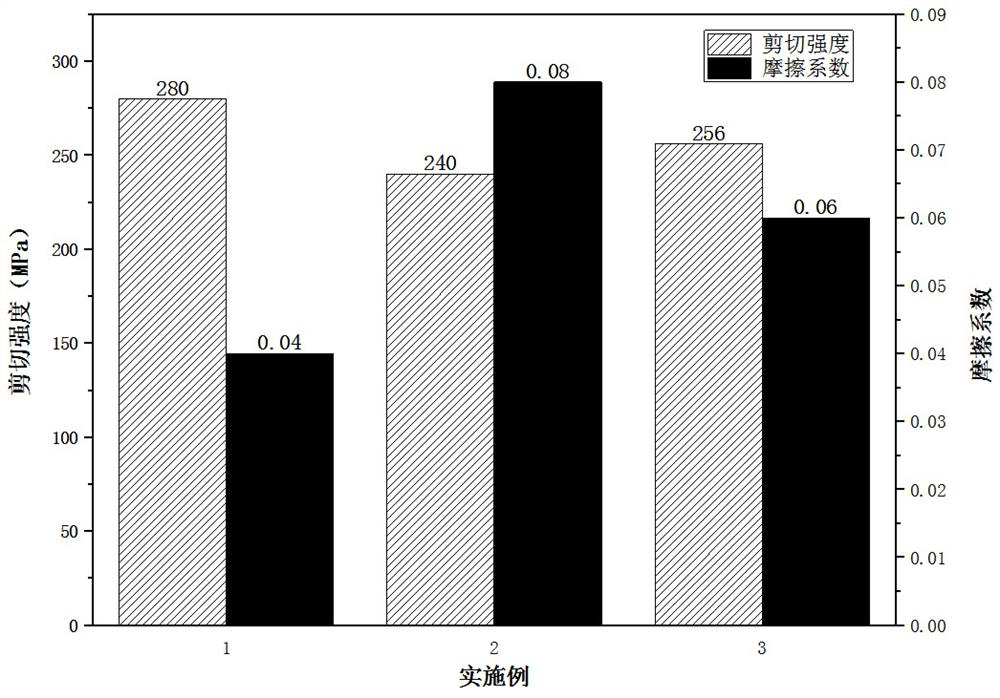

Embodiment 1

[0026] The welding operation steps of a high bonding strength copper-steel bimetallic anti-friction and wear-resistant composite material are as follows:

[0027] (1) Machine 45# steel and lead bronze alloy rod (ZCuSn10Pb10) respectively to obtain a steel substrate with a size of Ø30×7mm and a copper sheet with a size of φ30×3mm. The surface of the steel substrate is sandblasted and cleaned with ethanol, and the surface of the copper alloy is Perform rough sanding.

[0028] (2) Weigh 6g of copper-tin alloy powder (CuSn10), and press the copper-tin alloy powder into a green body in a hydraulic press, and the pressure for pressing the green body is 750MPa.

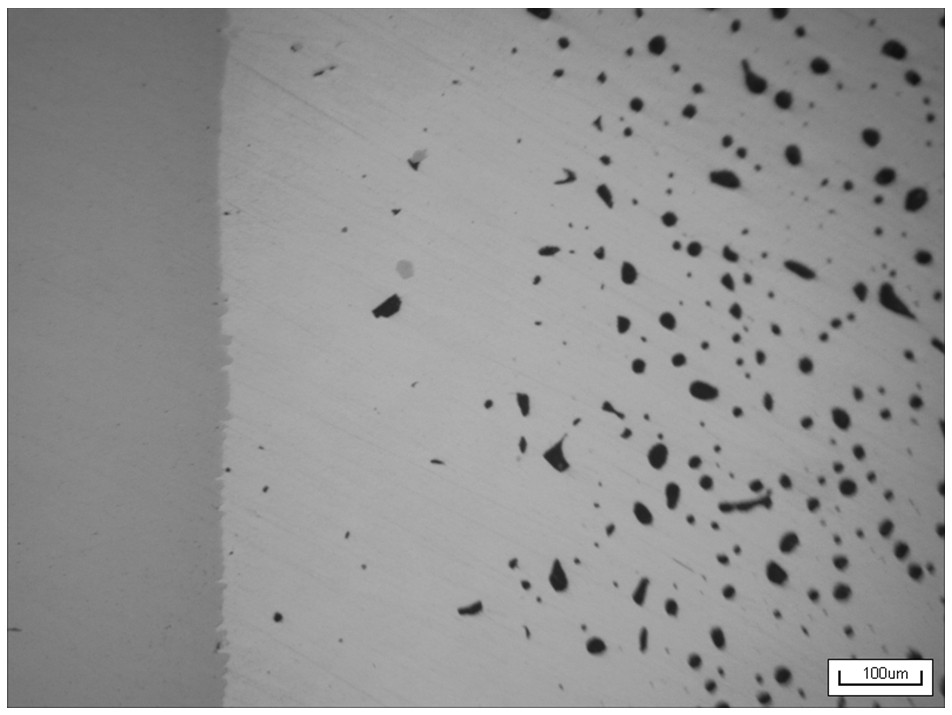

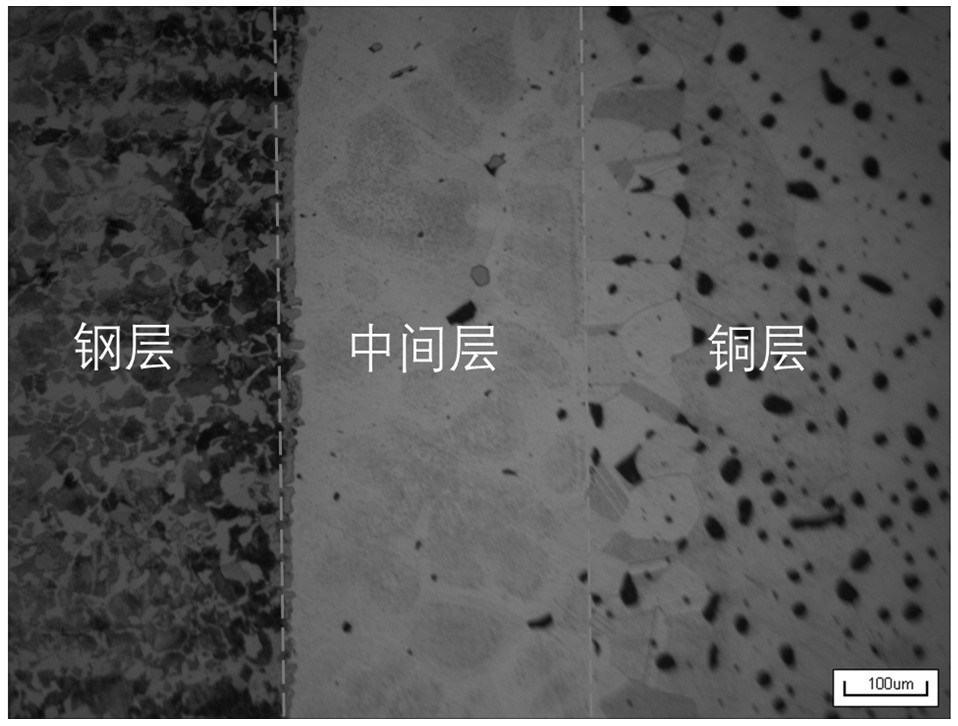

[0029] (3) Combine the green body in step 2 with the steel substrate treated in step 1 and put it into a mesh belt furnace for sintering and cladding. The temperature in the first zone is 680°C, the temperature in the second zone is 770°C, and the temperature in the third zone is 870°C, the temperature in zones 4 to 6 is 11...

Embodiment 2

[0034] Step (1) is the same as embodiment 1;

[0035] Step (2) is the same as embodiment 1;

[0036] Step (3), combine the green body in step 2 with the steel substrate treated in step 1 and put it into a mesh belt furnace for sintering and cladding. The temperature in the first zone is 680°C, the temperature in the second zone is 770°C, and the temperature in the third zone The temperature is 870°C, the temperature in zones 4 to 6 is 1100°C, the lengths of the mesh belts corresponding to each temperature zone are 2.45m, 2.45m, 2.45m, and 7.35m, and the belt speed is 70mm / min. During this period, the copper-tin alloy powder is completely A liquid phase is formed to spread and wet the surface of the steel substrate. Choose N 2 +H 2 As a protective atmosphere, it ensures production safety and prevents the generation of inclusions and oxides at the interface. After a period of time in the high temperature zone, metallurgical bonding occurs at the copper / steel interface, which ...

Embodiment 3

[0041] Step (1) is the same as embodiment 1;

[0042] Step (2) is the same as embodiment 1;

[0043] Step (3), combine the green body in step 2 with the steel substrate treated in step 1 and put it into a mesh belt furnace for sintering and cladding. The temperature in the first zone is 680°C, the temperature in the second zone is 770°C, and the temperature in the third zone The temperature is 870°C, the temperature in zones 4 to 6 is 1150°C, the lengths of mesh belts corresponding to each temperature zone are 2.45m, 2.45m, 2.45m, and 7.35m, and the belt speed is 70mm / min. During this period, the copper-tin alloy powder is completely A liquid phase is formed to spread and wet the surface of the steel substrate. Choose N 2 +H 2 As a protective atmosphere, it ensures production safety and prevents the generation of inclusions and oxides at the interface. After a period of time in the high temperature zone, metallurgical bonding occurs at the copper / steel interface, which grea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com