Reinforcing steel bar sleeve connecting structure, segmental prefabricated assembled pier and construction method

A prefabricated assembly and casing connection technology, applied in the field of bridge structure construction, can solve the problems of mismatch between structural settings and actual force, inability to set concave and convex shear keys, weak shear structure of joint surfaces, etc., to prevent premature The effect of buckling, enhanced bending resistance, and increased tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

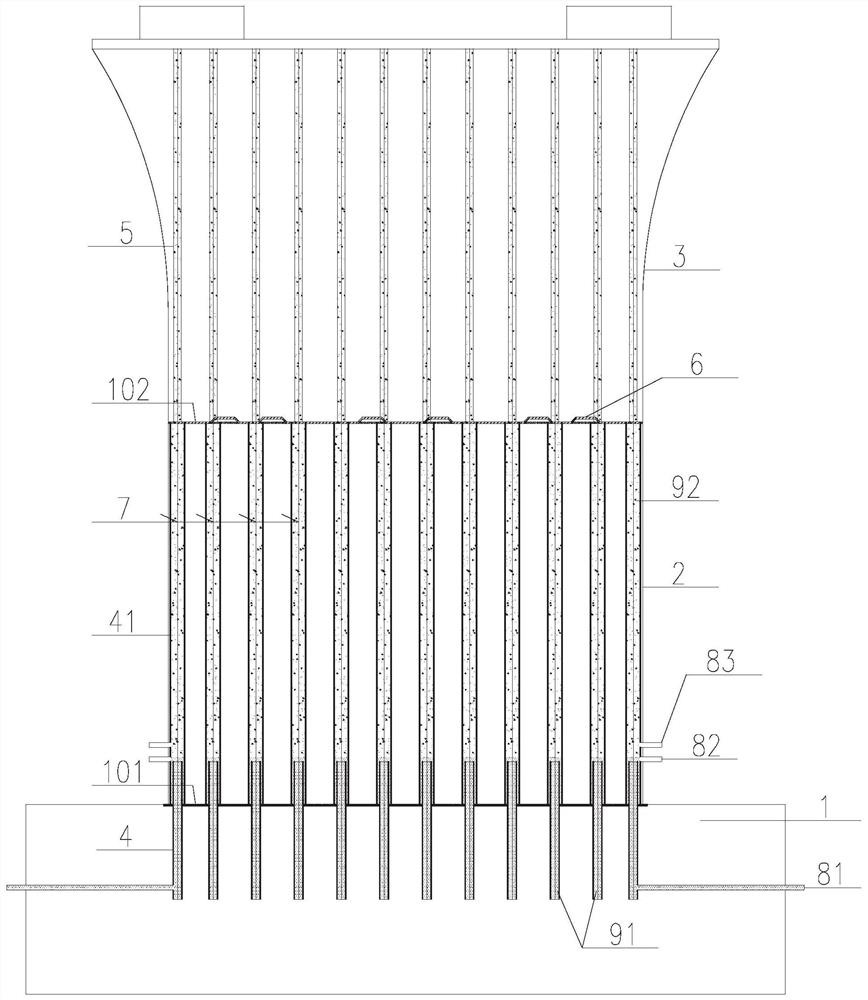

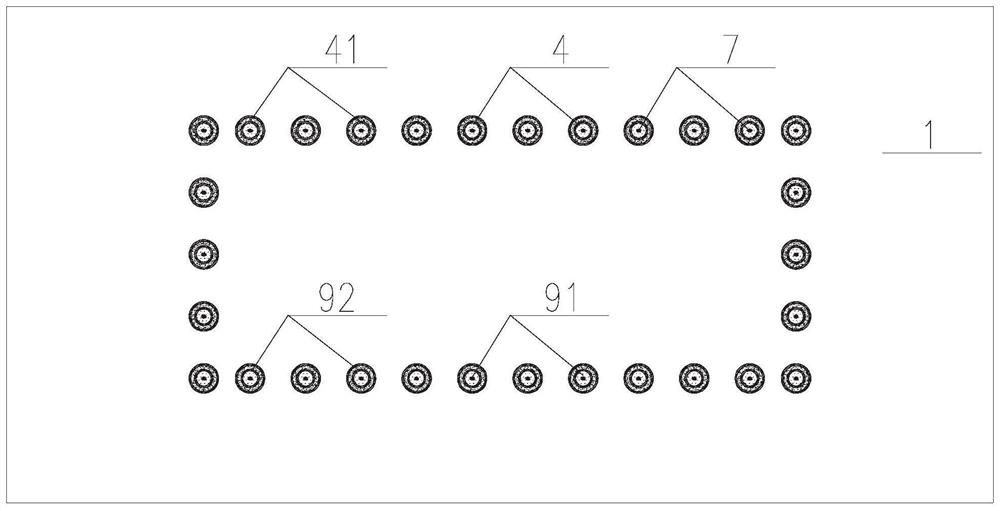

[0057] Such as Figure 1-2 As shown, a segmental prefabricated assembled pier steel casing connection structure, including:

[0058] During the foundation construction, according to the reinforcement arrangement, a plurality of bottom seam reinforcement sleeves 4 are pre-buried in the corresponding positions in the foundation 1, and the bottom seam reinforcement sleeves 4 protrude from the top surface of the foundation 1, so that the bottom seam reinforcement sleeves 4 pass through Bottom joint (the bottom joint refers to the splicing structure between the foundation cast on site and the bottom segment prefabricated in the factory, generally using high-strength mortar);

[0059] When the bottom segment 2 is prefabricated in the factory, a plurality of bottom segment reinforcement sleeves 41 are pre-embedded in corresponding positions in the bottom segment 2, and the length of the bottom segment reinforcement sleeves 41 is equal to or extended from the bottom surface of the bot...

Embodiment 2

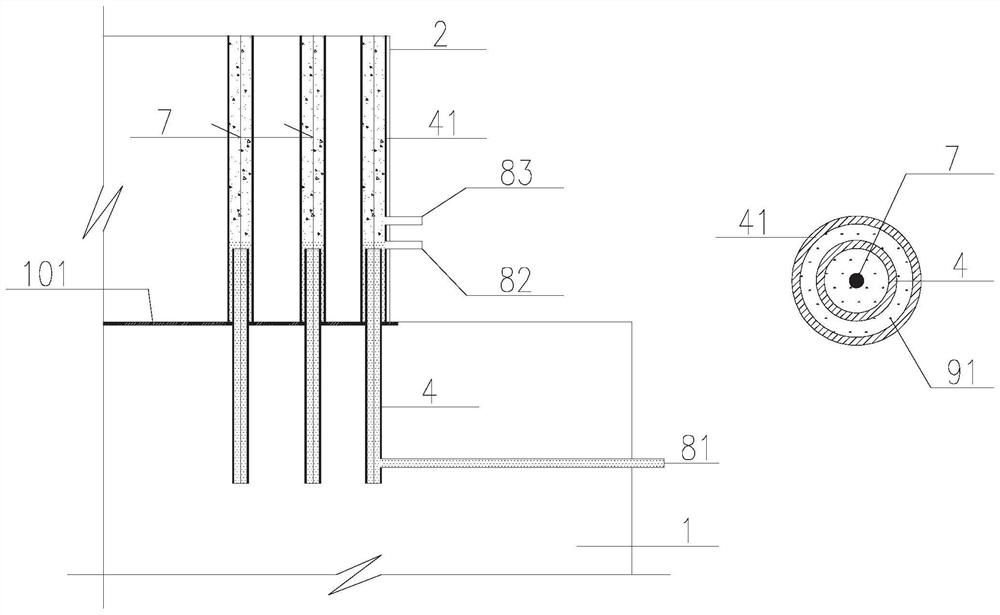

[0074] Such as Figure 4 As shown, a segmental prefabricated assembled pier steel casing connection structure, including:

[0075] According to the arrangement of steel bars during foundation construction, a plurality of steel bar casing channels 42 are reserved in corresponding positions in the foundation 1;

[0076] When the bottom segment 2 is prefabricated in the factory, a plurality of bottom seam reinforcement sleeves 4 are embedded in corresponding positions in the bottom segment 2, and the bottom seam reinforcement sleeves 4 extend out of the bottom segment 2 by a certain length, so that the bottom joint Sew reinforcement casing 4 through the bottom seam.

[0077] The steel bar casing tunnel 42 and the bottom joint steel reinforcement casing 4 are provided in one-to-one correspondence, and the bottom seam steel casing 4 is penetrated into the steel reinforcement casing tunnel 42 one by one, and each corresponding bottom seam steel casing 4 A long steel bar 7 runs thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com