Hexagonal nano boron nitride preparation method based on cholate intercalation and ball-milling stripping

A nano-boron nitride, cholate technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of low peeling efficiency, uneven quality and shape of nanomaterials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

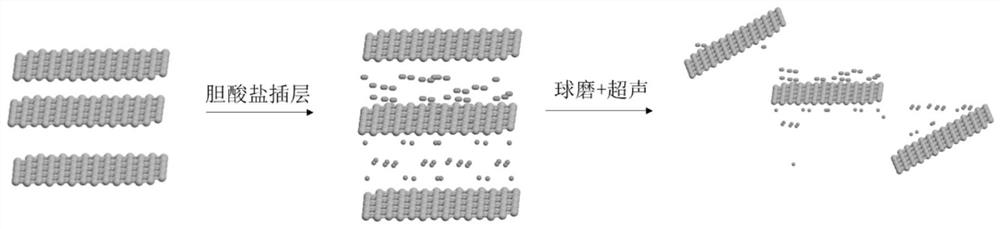

Method used

Image

Examples

Embodiment 1

[0023] (1) Ingredients, add 2g boron nitride and 2g SiC microspheres (as grinding balls) to the ball mill, then add 0.2g sodium cholate as intercalation agent, and water as solvent.

[0024] (2) Ball milling, put the prepared materials into the ball mill, adjust the speed to 150r / min, and ball mill for 15h.

[0025] (3) Ultrasonic. After the ball milling, perform ultrasonic at 500w for 10min.

[0026] (4) centrifuge, put the material finished by ultrasonic into the centrifuge, the rotating speed is 2200r / min, centrifugal 10min.

[0027] (5) Collecting, taking the supernatant from the centrifuged material and drying it as the final product.

Embodiment 2

[0029] (1) Ingredients, add 2g of boron nitride and 2g of SiC microspheres into the ball mill, then add 0.2g of sodium deoxycholate as an intercalation agent, and water as a solvent.

[0030] (2) Ball milling, put the prepared materials into the ball mill, adjust the speed to 250r / min, and ball mill for 10h.

[0031] (3) Ultrasound. After the ball milling, perform ultrasonication at 100w for 20min.

[0032] (4) centrifuge, put the material finished by ultrasonic into the centrifuge, the rotating speed is 1800r / min, centrifugal 20min.

[0033] (5) Collecting, taking the supernatant from the centrifuged material and drying it as the final product.

Embodiment 3

[0035] (1) Ingredients, add 2g of boron nitride and 3g of SiC microspheres into the ball mill, then add 0.2g of sodium taurocholate as an intercalation agent, and water as a solvent.

[0036] (2) Ball milling, put the prepared materials into the ball mill, adjust the speed to 200r / min, and ball mill for 12h.

[0037] (3) Ultrasonic. After the ball milling, perform ultrasonic at 300w for 15min.

[0038] (4) centrifuge, put the material finished by ultrasonic into the centrifuge, the rotating speed is 2000r / min, centrifugal 15min.

[0039] (5) Collecting, taking the supernatant from the centrifuged material and drying it as the final product.

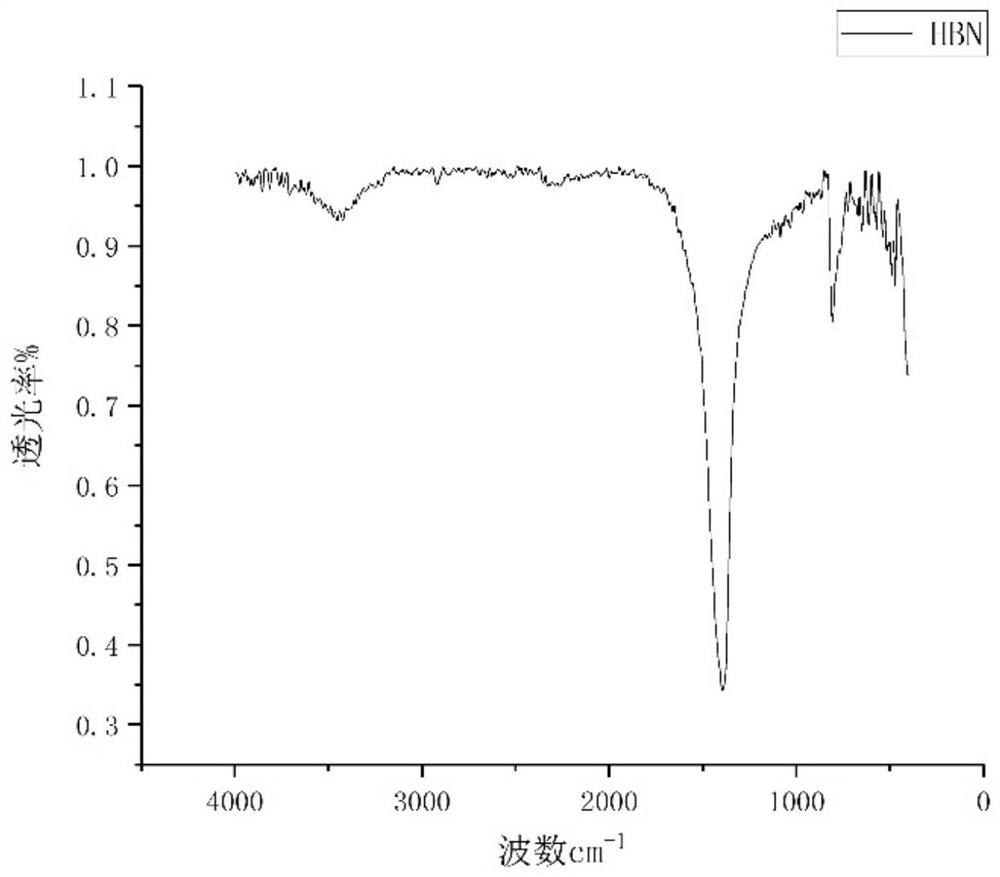

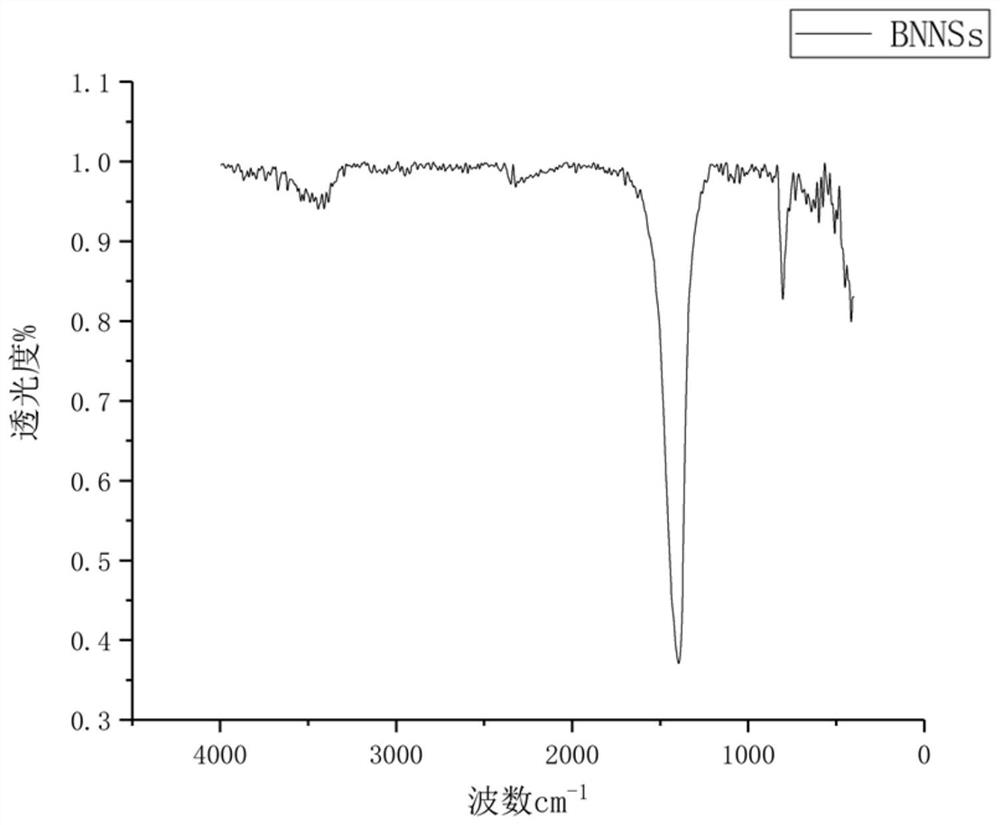

[0040] Taking Examples 1-3 as the object of characterization, a small amount of centrifuged boron nitride supernatant was taken in a petri dish, and dried in an oven for 24 hours to obtain white boron nitride powder. The samples for infrared spectroscopy were prepared by the halide tablet method. Potassium bromide and boron nitride were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com