Concrete quality detection device

A detection device, concrete technology, applied in the direction of measurement device, application of stable tension/pressure to test material strength, comprehensive factory control, etc., can solve problems such as pressure sensor damage, pressure sensor surface scratches, etc., to achieve the effect of easy fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

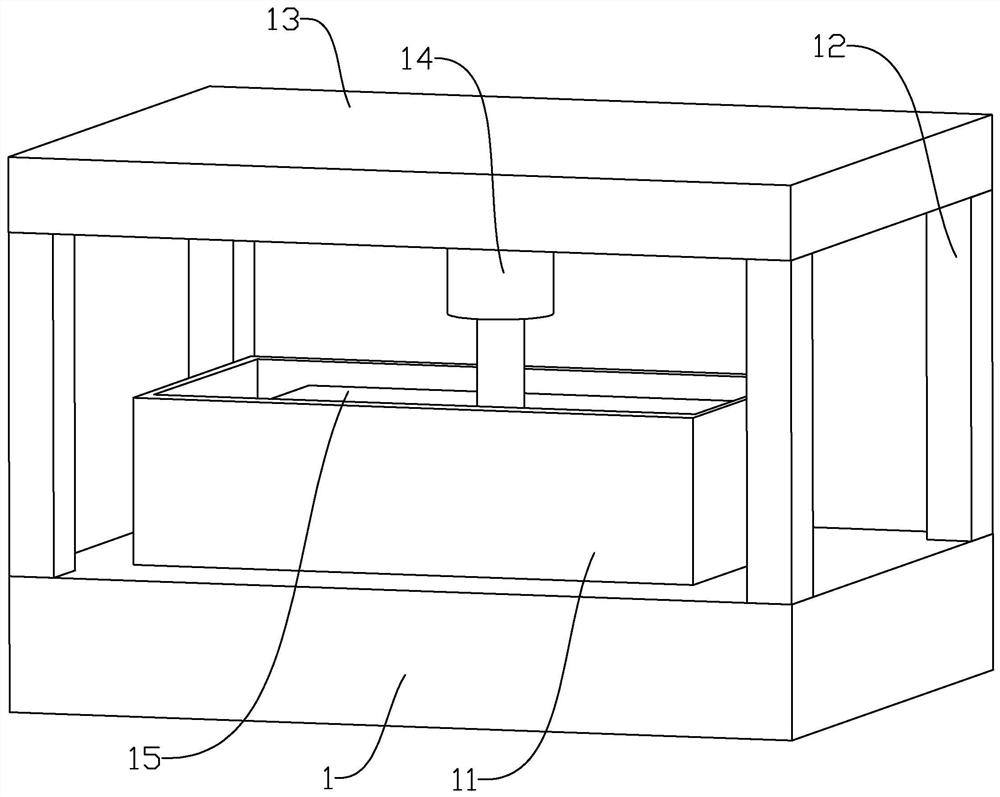

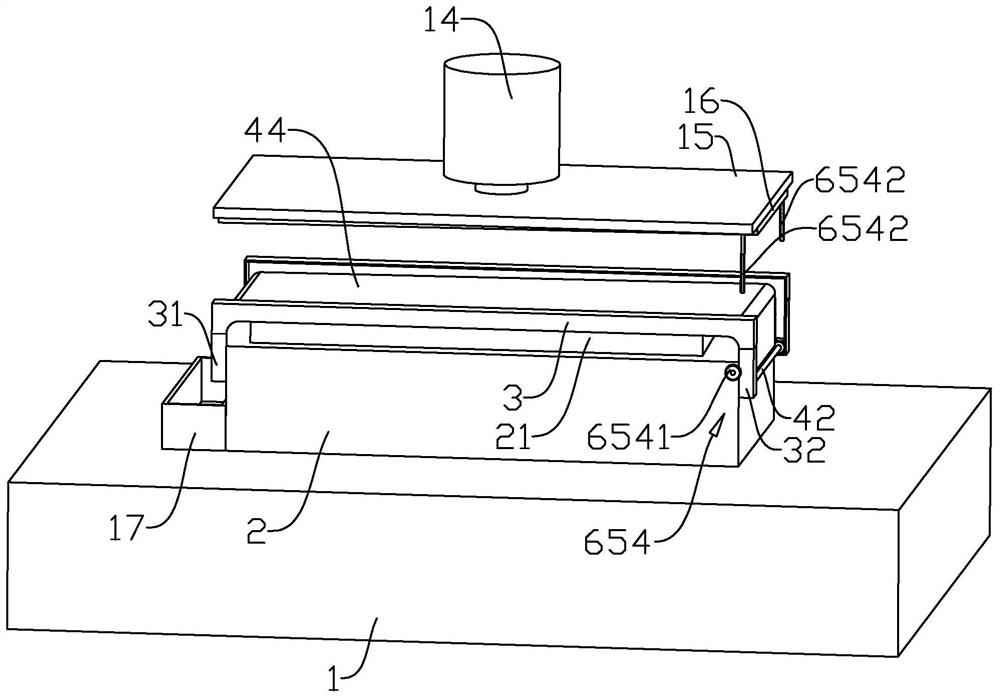

[0039] Contraction below Figure 1-7 Further detailed description of the present application.

[0040] The present application example discloses a quality detection device for concrete, such as figure 1 with figure 2 As shown, including the apparatus body 1, the table 2, the support rod 12, the support plate 13, the cylinder 14, the mounting plate 15, the pressure plate 16, the splash frame 11, and the pressure sensor 21, the support rod 12 is four, four support rods. 12 is vertically disposed, and the four support rods 12 are fixedly coupled to the upper surface of the apparatus body 1, and the four support rods 12 are uniformly distributed at four corners of the apparatus body 1. The support plate 13 is located above the support rod 12, and the bottom side of the support plate 13 is simultaneously coupled to the top end of the four support rods 12. The cylinder 14 is mounted on the bottom side of the support plate 13, and the mounting plate 15 is fixedly coupled to the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com