Densification treatment method of spray deposition ultrahigh-strength aluminum alloy, application and densified preformed blank prepared through densification treatment method

A treatment method and spray deposition technology, applied in the field of densification of preforms and spray deposition of ultra-high-strength aluminum alloys, can solve problems such as low performance, improve plasticity, good surface quality, prevent cracking or cannot be formed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The total alloy content of the spray-deposited 7034 ultra-high-strength aluminum alloy exceeds 12%, and the density of the spray-deposited blank is 96.5%. The material in this state is very brittle, and direct pierce or die forging often leads to cracking.

[0033] A method for densification of ultra-high-strength aluminum alloys by spray deposition, comprising the following steps:

[0034] Step 1, prepare preform

[0035] The spray-deposited 7034 ultra-high-strength aluminum alloy billet is processed into a cylindrical preform, wherein the diameter of the bottom surface of the cylindrical preform is D=50mm, and the height h=120mm.

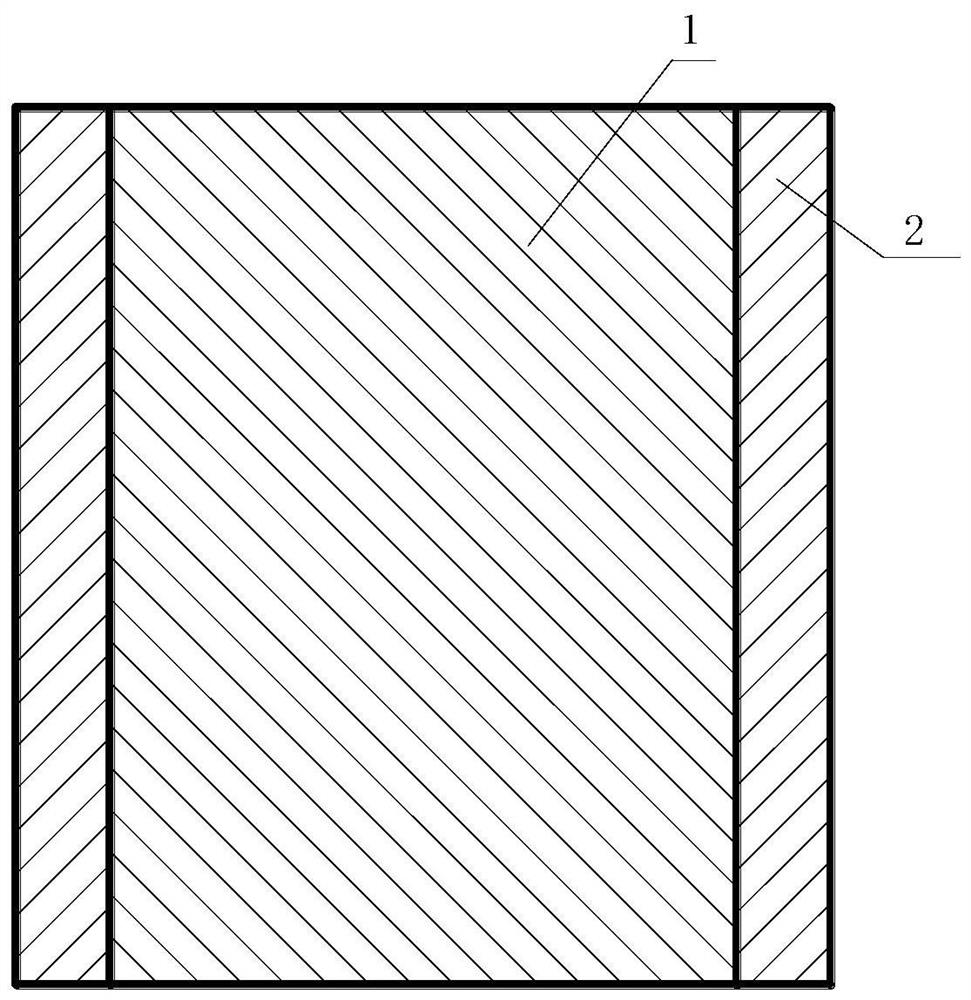

[0036] Step 2. Prepare surrounding materials

[0037] The 7A60 aluminum alloy with better plasticity is used as the surrounding material to process a cylindrical surrounding ring. The inner circle diameter of the cylindrical surrounding ring is d=50mm, the height h=120mm, and the wall thickness is 8mm. The inner circle of the cylindrical s...

Embodiment 2

[0049] The total alloy content of the spray-deposited 7136 ultra-high-strength aluminum alloy exceeds 12%, and the density of the spray-deposited blank is 96.8%. The material in this state is very brittle, and direct pierce or die forging often leads to cracking.

[0050] A method for densification of ultra-high-strength aluminum alloys by spray deposition, comprising the following steps:

[0051] Step 1, prepare preform

[0052] The spray-deposited 7136 ultra-high-strength aluminum alloy billet is processed into a cylindrical preform, wherein the diameter of the bottom surface of the cylindrical preform is D=100mm, and the height h=60mm.

[0053] Step 2. Prepare surrounding materials

[0054] The 7075 aluminum alloy with better plasticity is used as the surrounding material to process a cylindrical surrounding ring. The inner circle diameter of the cylindrical surrounding ring is d=100mm, the height h=60mm, and the wall thickness is 20mm. The inner circle of the cylindrical su...

Embodiment 3

[0065] The total alloy content of the spray-deposited 7093 ultra-high-strength aluminum alloy exceeds 12%, and the density of the spray-deposited blank is 95.6%. The material in this state is very brittle, and direct pierce or die forging often leads to cracking.

[0066] A method for densification of ultra-high-strength aluminum alloys by spray deposition, comprising the following steps:

[0067] Step 1, prepare preform

[0068] The spray-deposited 7093 ultra-high-strength aluminum alloy billet is processed into a cylindrical preform, wherein the diameter of the bottom surface of the cylindrical preform is D=80mm, and the height h=100mm.

[0069] Step 2. Prepare surrounding materials

[0070] The 7D68 aluminum alloy with better plasticity is used as the surrounding material to process a cylindrical surrounding ring. The inner circle diameter of the cylindrical surrounding ring is d=80mm, the height h=100mm, and the wall thickness is 15mm. The inner circle of the cylindrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com