High-carbon steel wire rod and production method thereof

A production method and high-carbon steel technology, applied in the direction of furnace type, heat treatment bath, heat treatment furnace, etc., can solve the problems of extremely poor tensile strength, affecting the service life safety factor of steel wire, etc., to avoid cracks, shorten phase transition time, The effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

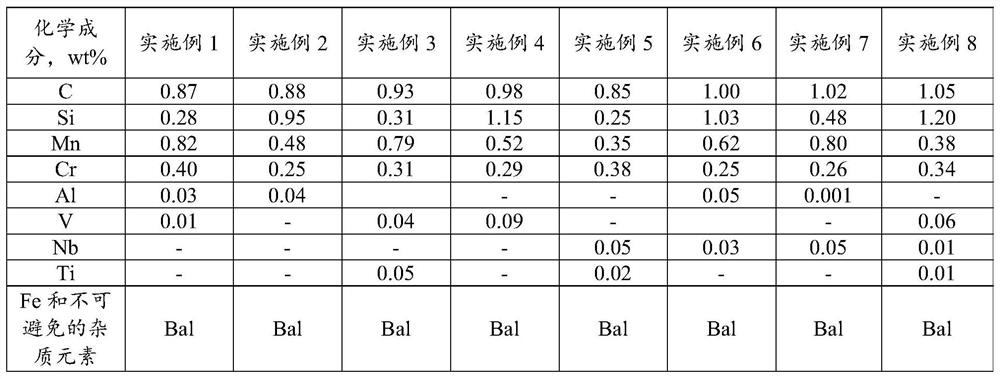

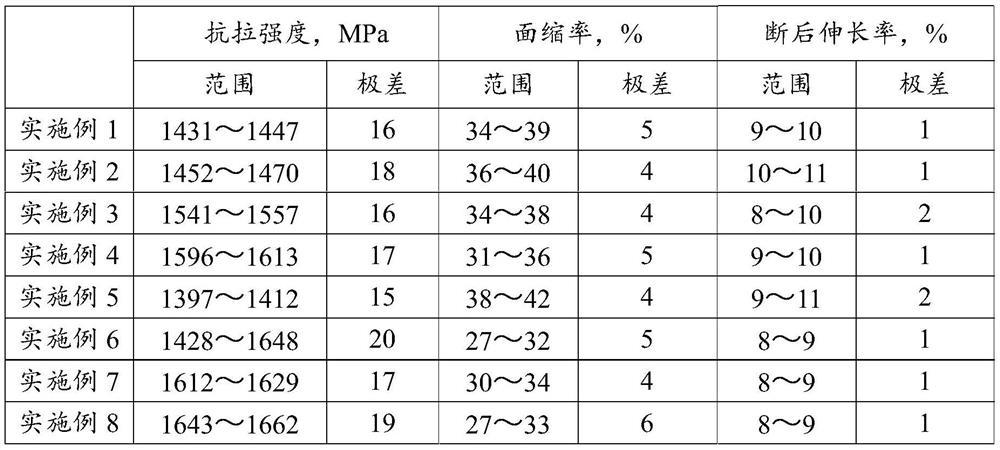

Examples

Embodiment 1

[0059] (1) Desulfurization of molten iron: KR desulfurization technology is adopted, and desulfurization agent is added to remove sulfur from molten iron, so as to control the S content in molten iron after desulfurization to 0.0035% by mass percentage.

[0060] (2) Converter smelting: the desulfurized molten iron obtained in the molten iron desulfurization process is moved into the converter, and mixed with high-quality scrap steel for oxygen blowing smelting, the tapping temperature is controlled at 1620 ° C, and the P in the molten steel at the end of the smelting is controlled as mass percentage. 0.009%.

[0061] (3) LF refining: the molten steel smelted in the converter is moved into the LF furnace for refining, the chemical composition of the molten steel is adjusted and controlled, and molten steel conforming to the design scheme of the chemical composition of the wire rod is obtained.

[0062] (4) Continuous casting process: control the superheat of the tundish to 21°C...

Embodiment 2

[0070] (1) Desulfurization of molten iron: KR desulfurization technology is adopted, and desulfurization agent is added to remove sulfur in molten iron, so as to control the S content in molten iron after desulfurization to 0.004% by mass percentage.

[0071] (2) Converter smelting: the desulfurized molten iron obtained in the molten iron desulfurization process is moved into the converter, and mixed with high-quality scrap steel for oxygen blowing smelting, the tapping temperature is controlled at 1641 ° C, and the P in the molten steel at the end of the smelting is controlled as mass percentage. 0.01%.

[0072] (3) LF refining: the molten steel smelted in the converter is moved into the LF furnace for refining, the chemical composition of the molten steel is adjusted and controlled, and molten steel conforming to the design scheme of the chemical composition of the wire rod is obtained.

[0073] (4) Continuous casting process: control the superheat of the tundish to 25°C, an...

Embodiment 3

[0081] (1) Desulfurization of molten iron: KR desulfurization technology is adopted, and desulfurization agent is added to remove sulfur from molten iron, so as to control the S content in molten iron after desulfurization to 0.005% by mass percentage.

[0082] (2) Converter smelting: the desulfurized molten iron obtained in the molten iron desulfurization process is moved into the converter, and mixed with high-quality scrap steel for oxygen blowing smelting, the tapping temperature is controlled at 1656 ° C, and the P in the molten steel at the end of the smelting is controlled as mass percentage. 0.009%.

[0083] (3) LF refining: the molten steel smelted in the converter is moved into the LF furnace for refining, the chemical composition of the molten steel is adjusted and controlled, and molten steel conforming to the design scheme of the chemical composition of the wire rod is obtained.

[0084] (4) Continuous casting process: control the superheat of the tundish to 20°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com