Chromium-containing hard alloy material and preparation process thereof

A cemented carbide and preparation technology, which is applied in the field of cemented carbide, can solve the problems of reducing the surface properties of products, and achieve the effects of improving electrical corrosion resistance, good comprehensive performance, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

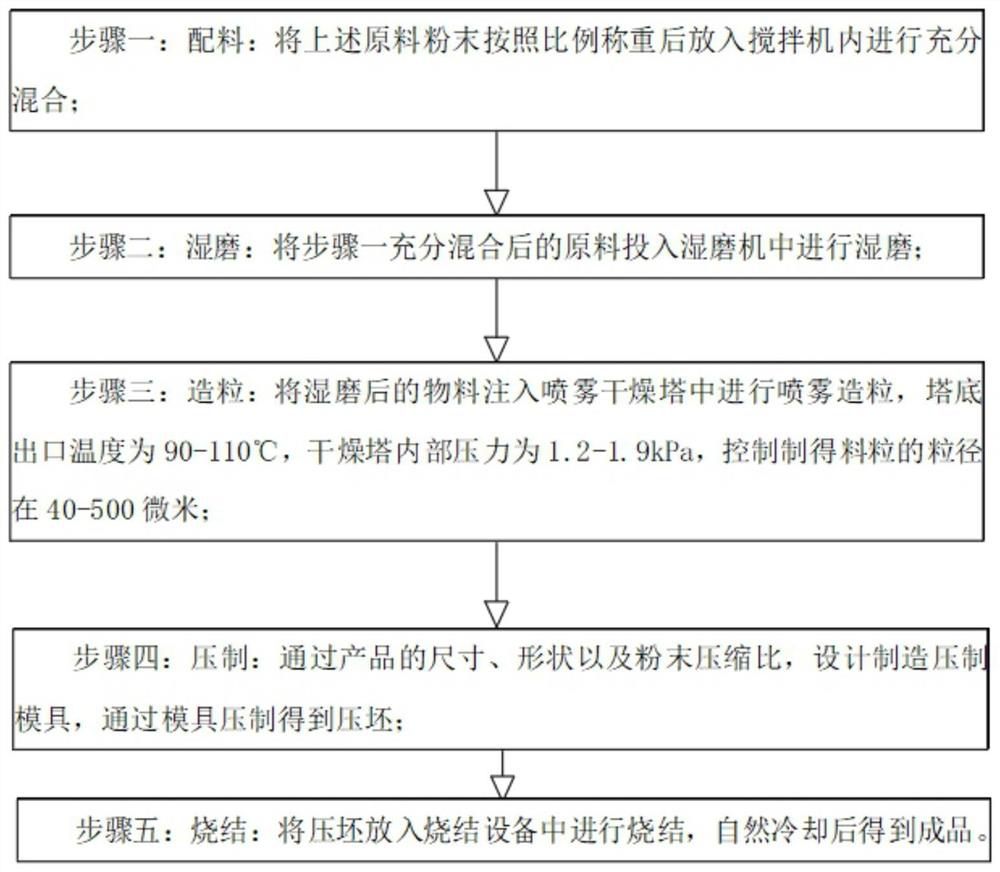

Method used

Image

Examples

Embodiment 1

[0025] A chromium-containing hard alloy material and a preparation process thereof, comprising:

[0026] Tungsten carbide powder, cobalt powder, nickel powder, chromium powder and molybdenum powder;

[0027] The nickel powder content is 3.0wt%, the chromium powder content is 2.0wt%, the molybdenum powder content is 0.5wt%, the cobalt powder content is 10.5wt%, and the tungsten carbide powder content is 84wt%.

[0028] In this embodiment, preferably, the tungsten carbide powder, cobalt powder, nickel powder, chromium powder and molybdenum powder are mixed and ground according to the above proportions in a mixer, the speed of the mixer is 450r / min, and the grinding time is 35min.

[0029] In this embodiment, preferably, nickel powder, chromium powder, cobalt powder and molybdenum powder form a solid-solution bonding phase during sintering, and tungsten carbide powder is used to increase the hardness of the alloy material.

[0030] In this embodiment, preferably, the FSSS partic...

Embodiment 2

[0042] A chromium-containing hard alloy material and a preparation process thereof, comprising:

[0043] Tungsten carbide powder, cobalt powder, nickel powder, chromium powder and molybdenum powder;

[0044] The nickel powder content is 1.5wt%, the chromium powder content is 1.5wt%, the molybdenum powder content is 0.3wt%, the cobalt powder content is 10wt%, and the tungsten carbide powder content is 86.7wt%.

[0045] In this embodiment, preferably, the tungsten carbide powder, cobalt powder, nickel powder, chromium powder and molybdenum powder are put into the mixer according to the above proportions for mixing and grinding, the speed of the mixer is 450r / min, and the grinding time is 55min.

[0046] In this embodiment, preferably, the nickel powder, the chromium powder, the cobalt powder and the molybdenum powder form a solid solution bonding phase during sintering, and the tungsten carbide powder is used to increase the hardness of the alloy material.

[0047] In this embo...

Embodiment 3

[0056] A chromium-containing hard alloy material and a preparation process thereof, comprising:

[0057] Tungsten carbide powder, cobalt powder, nickel powder, chromium powder and molybdenum powder;

[0058] The nickel powder content is 2.0 wt%, the chromium powder content is 1.5 wt%, the molybdenum powder content is 0.2 wt%, the cobalt powder content is 11 wt%, and the tungsten carbide powder content is 85.3 wt%.

[0059] In this embodiment, preferably, the tungsten carbide powder, cobalt powder, nickel powder, chromium powder and molybdenum powder are mixed and ground according to the above proportions in a mixer, the speed of the mixer is 450r / min, and the grinding time is 45min.

[0060] In this embodiment, preferably, the nickel powder, the chromium powder, the cobalt powder and the molybdenum powder form a solid solution bonding phase during sintering, and the tungsten carbide powder is used to increase the hardness of the alloy material.

[0061] In this embodiment, pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com