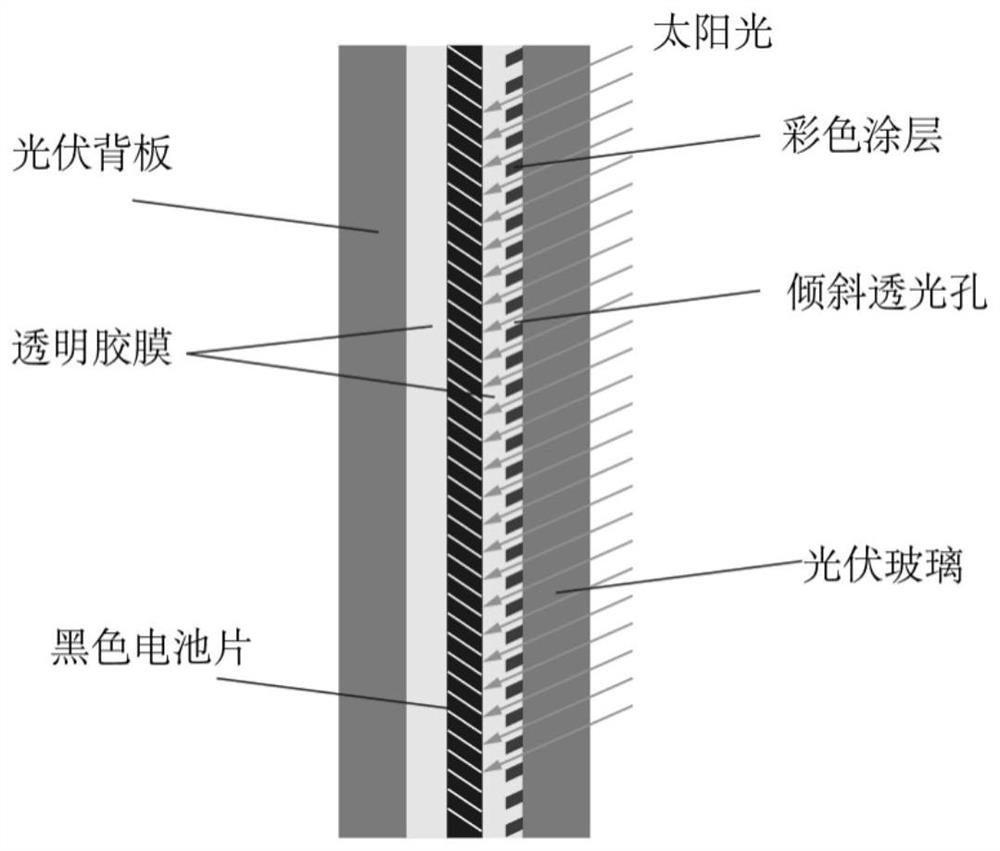

Solar glass panel with honeycomb-shaped colored tempered coating, production method of solar glass panel and colored solar photovoltaic module

A technology of solar glass and a production method, which is applied in the field of solar photovoltaics, can solve problems such as being unable to be used on the outer surface of photovoltaic module glass, low light transmittance of inorganic coatings, and no practical application value, so as to reduce the probability of burning photovoltaic modules, Excellent outdoor weather resistance and the effect of widening the range of color choices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

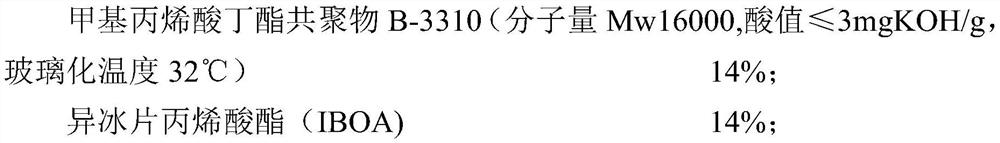

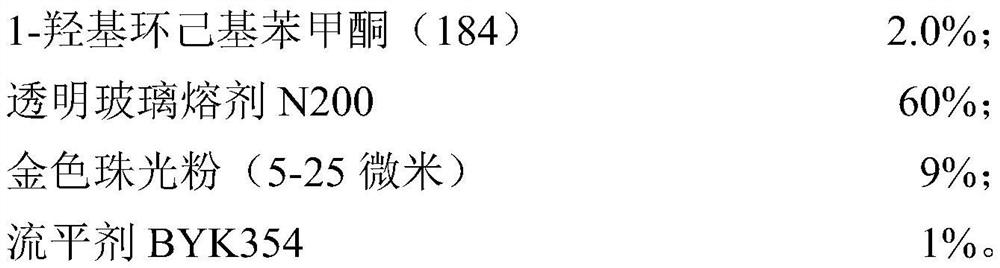

[0061] Golden honeycomb tempered UV coating formula (mass percentage of raw materials):

[0062]

[0063]

[0064] Stir and dissolve the B-3310 and IBOA in the above formula at 60-80°C to form a homogeneous liquid, mix with the other components evenly to obtain a colored UV coating, and print the above UV coating with a 200-mesh screen to obtain a thickness of 20 Micron color coating; UV light curing, irradiation energy 600 mJ / cm2; use a green laser with a wavelength of 532 nm and a power of 10 watts to drill holes at an angle of 45 degrees to the glass, with a diameter of 15 microns, and the area of the hole and the coating The ratio is 10%; the punched glass is directly sent into a tempering furnace for tempering (780-820°C / 220 seconds), and a golden honeycomb tempered glass coating is obtained. Viewed from a distance, it is golden glass with uniform color, but viewed from a close distance, there are many oblique light-transmitting small holes on the surface. The phy...

Embodiment 2

[0066] Blue honeycomb tempered UV coating formula (mass percentage of raw materials):

[0067]

[0068] Stir and dissolve the B-3131 polymer and HDDA in the above formula at 60-80°C to form a homogeneous liquid, mix with the other components evenly to obtain a colored UV coating, and print the above UV coating with a 200-mesh screen to obtain Thickness 18 micron blue coating. The UV light curing energy is 1100 mJ / cm2, and the green laser with a wavelength of 532 nm and a power of 10 watts is used to drill holes at an angle of 45 degrees to the glass. The hole diameter is 15 microns, and the ratio of the hole to the coating area is 20%. The glass is directly sent into the tempering furnace for tempering (780-820°C / 220 seconds), and the blue honeycomb tempered glass coating is obtained. It is uniform blue glass when viewed from a distance, and there are many oblique light transmissions on the surface when viewed closely. For small holes, measure physical and chemical indicat...

Embodiment 3

[0070] White honeycomb tempered UV coating formula (mass percentage of raw materials):

[0071]

[0072] Stir and dissolve the B-3131 polymer and IBOMA in the above formula at 60-80°C to form a homogeneous liquid, and mix with the rest of the components evenly to obtain a colored UV coating; screen the above UV coating with a 200-mesh screen to obtain a thickness of 20 microns Color coating. UV light curing, irradiation energy 1500 mJ / cm2. A green laser with a wavelength of 532 nanometers and a power of 10 watts is used to drill holes at an angle of 45 degrees to the glass. The hole diameter is 15 microns, and the ratio of the hole to the coating area is 25%. The perforated glass is sent directly to the tempering furnace for tempering (780-820°C / 220 seconds), and a white honeycomb color tempered glass panel is obtained. It is white glass with uniform color when viewed from a distance, and there are many inclinations on the surface when viewed from a close distance. Light-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com