A kind of preparation method of heavy calcium carbonate for silicone rubber with high activation degree

A heavy calcium carbonate, activation degree technology, applied in chemical instruments and methods, adhesives, non-polymer adhesive additives, etc., can solve the problem of single-component modifier with single effect, poor modification effect and high preparation cost problem, to achieve the effect of simple and easy preparation method, low oil absorption value and low specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

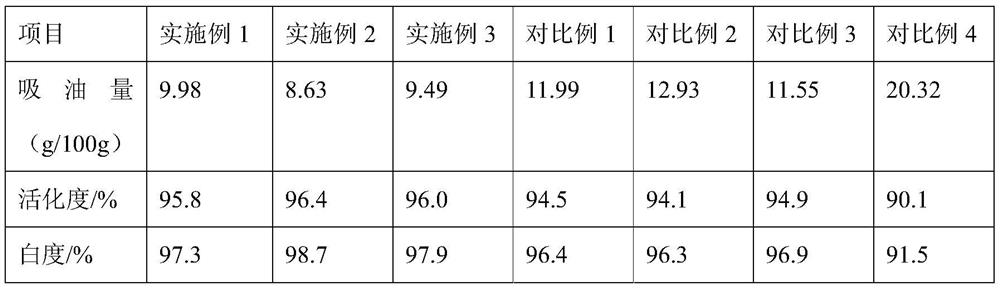

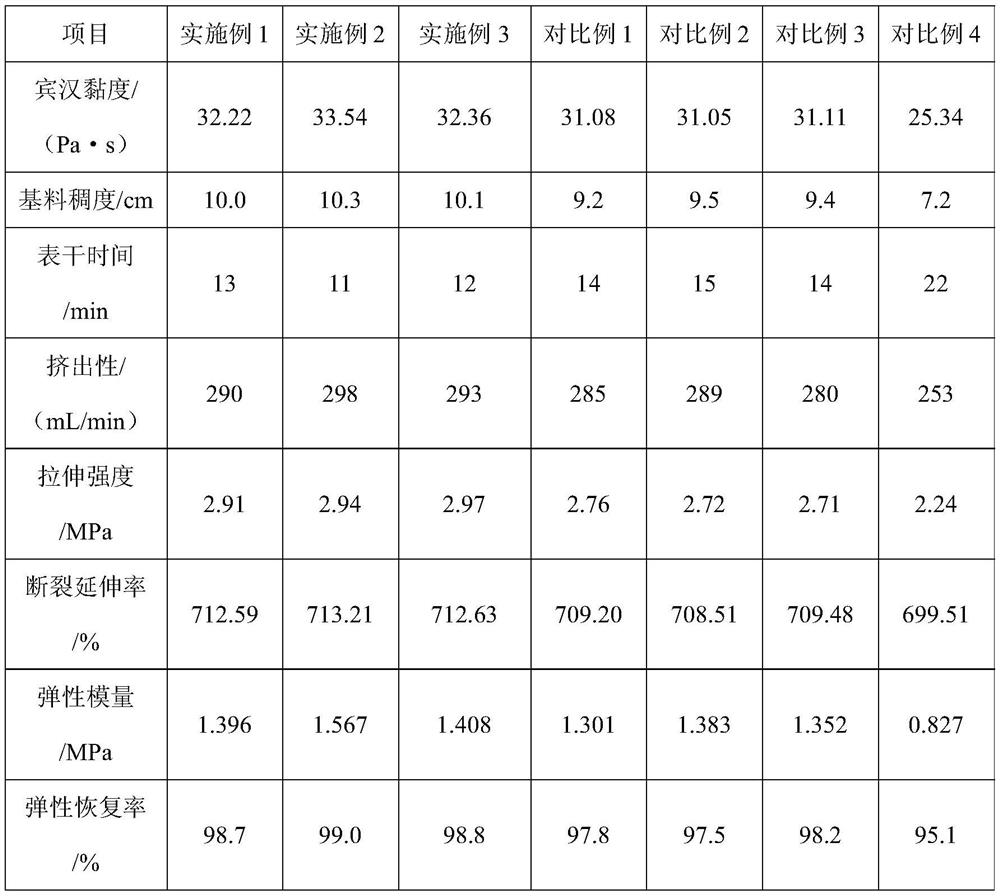

Examples

Embodiment 1

[0032] A preparation method of heavy calcium carbonate for high-activation silicone rubber, which sequentially includes ore storage, cleaning, beneficiation, crushing and homogenization, grinding, grading, powder collection, quality inspection I, activation, cooling, and quality inspection II steps ;

[0033] The described ore storage steps are: storing the ore raw materials separately according to ore types and grades;

[0034] The cleaning steps are: cleaning the mud stuck on the surface of the ore with water;

[0035]The ore dressing step is: selecting the unqualified ore entrained in the ore; the unqualified ore is the ore with low whiteness, skin and other impurities;

[0036] The crushing and homogenizing step is as follows: crush the qualified ore into 18mm ore, and then send it into a 10,000-ton level homogenizing tank for homogenizing;

[0037] The grinding step is: sending the mineral material into the grinding equipment for grinding;

[0038] The grading step is:...

Embodiment 2

[0045] A preparation method of heavy calcium carbonate for high-activation silicone rubber, which sequentially includes ore storage, cleaning, beneficiation, crushing and homogenization, grinding, grading, powder collection, quality inspection I, activation, cooling, and quality inspection II steps ;

[0046] The described ore storage steps are: storing the ore raw materials separately according to ore types and grades;

[0047] The cleaning steps are: cleaning the mud stuck on the surface of the ore with water;

[0048] The ore dressing step is: selecting the unqualified ore entrained in the ore; the unqualified ore is the ore with low whiteness, skin and other impurities;

[0049] The crushing and homogenizing step is as follows: crushing the qualified ore into 15mm ore, and then sending it into a 10,000-ton level homogenizing tank for homogenizing;

[0050] The grinding step is: sending the mineral material into the grinding equipment for grinding;

[0051] The grading s...

Embodiment 3

[0058] A preparation method of heavy calcium carbonate for high-activation silicone rubber, which sequentially includes ore storage, cleaning, beneficiation, crushing and homogenization, grinding, grading, powder collection, quality inspection I, activation, cooling, and quality inspection II steps ;

[0059] The described ore storage steps are: storing the ore raw materials separately according to ore types and grades;

[0060] The cleaning steps are: cleaning the mud stuck on the surface of the ore with water;

[0061] The ore dressing step is: selecting the unqualified ore entrained in the ore; the unqualified ore is the ore with low whiteness, skin and other impurities;

[0062] The crushing and homogenizing step is as follows: crush the qualified ore into a 10mm mineral material, and then send it into a 10,000-ton level homogenizing tank for homogenizing;

[0063] The grinding step is: sending the mineral material into the grinding equipment for grinding;

[0064] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com