Dy<3+>-doped phosphate glass for outputting yellow laser, optical fiber and preparation method of Dy<3+>-doped phosphate glass

A phosphate glass and laser technology, applied in glass manufacturing equipment, glass fiber products, clad optical fiber, etc., can solve the problems of poor yellow light gain performance, low output power and efficiency, complicated preparation process, etc., to reduce particle size Difficulty in number reversal, high degree of asymmetry, high power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Dy 3+ Melting of doped phosphate bulk core glass: Melting bulk Dy by melting-annealing method 3+ Doped phosphate bulk core glass. The ratio of the oxide raw materials of the glass is as follows (mol%):

[0050] P 2 o 5 :65%

[0051] K 2 O: 13%

[0052] BaO: 12%

[0053] Al 2 o 3 :5%

[0054] La 2 o 3 :4%

[0055] Dy 2 o 3 :1%

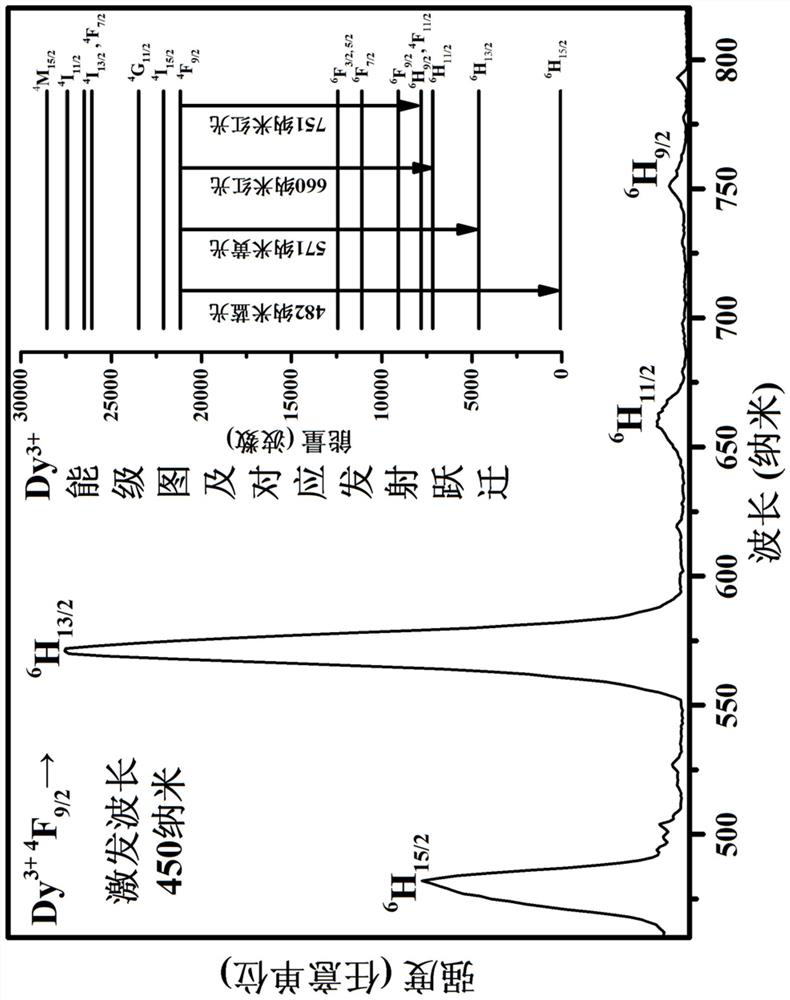

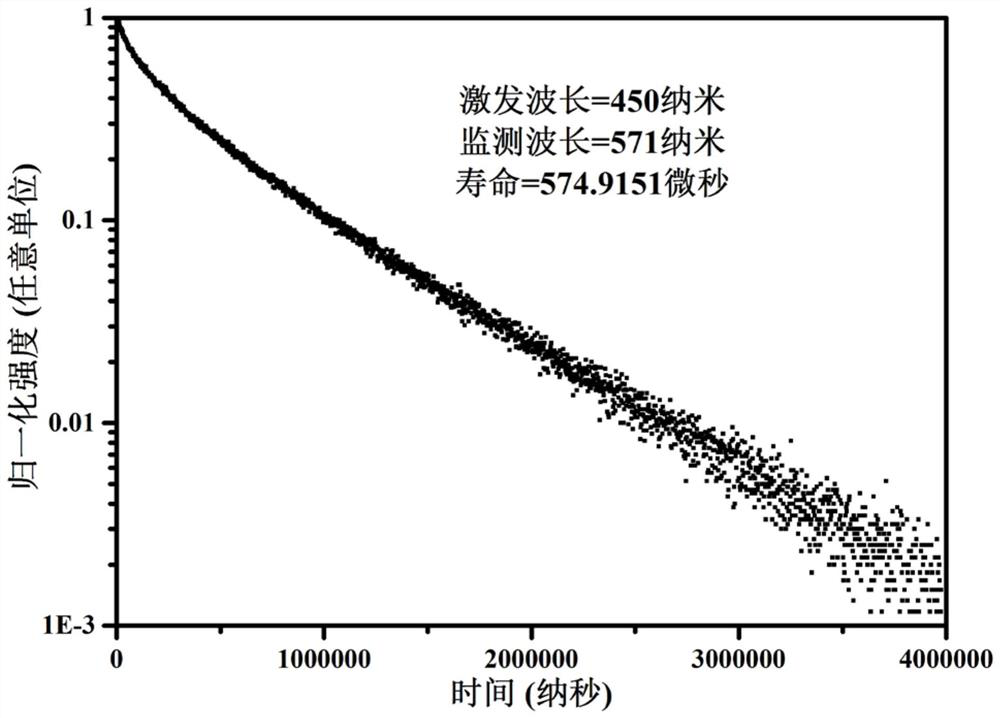

[0056] Accurately weigh P according to the above ratio 2 o 5 、K 2 CO 3 、BaCO 3 、Al 2 o 3 , La 2 o 3 and Dy 2 o 3 Wait for 500g of the corresponding raw materials of each oxide, put them in a mortar and grind them for 30 minutes to mix them evenly, and then melt them in a corundum crucible at 1250°C for 2 hours including steps of water removal, stirring and clarification. Then pour it into an iron mold preheated to 500°C for molding, and then quickly put it into a muffle furnace for precise gradient annealing at 500°C to obtain Dy 3+ Doped phosphate bulk core glass. The absorption cross section, emission spectrum a...

Embodiment 2

[0071] Tb 3+ and Eu 3+ Due to having with Dy 3+ lower level of yellow emission 6 h 13 / 2 A relatively matched energy level can effectively quench Dy by means of energy transfer 3+ lower level of yellow emission 6 h 13 / 2 , which reduces the Dy 3+ The difficulty of realizing the inversion of the number of particles is conducive to improving the emission power and slope efficiency of the yellow laser while reducing the emission threshold. The embodiment is basically the same as Example 1, except that 0.5 mole percent Tb is added to the core glass component 2 o 3 or Eu 2 o 3 , while deducting the same amount of P 2 o 5 . This method can be used to prepare Dy for outputting yellow laser light 3+ / Tb 3+ Co-blended or Dy 3+ / Eu 3+ Co-doped phosphate glass fiber.

[0072] Figure 4 Dy in this example 3+ / Tb 3+ Co-doped phosphate glass fiber and Dy in embodiment 1 3+ Comparison of the emission spectra of doped phosphate glass fiber, the emission peaks are marked wi...

Embodiment 3

[0074] (1) Dy 3+ Melting of doped phosphate bulk core glass: Melting bulk Dy by melting-annealing method 3+ Doped phosphate bulk core glass. The ratio of the oxide raw materials of the glass is as follows (mol%):

[0075] P 2 o 5 :70%

[0076] K 2 O: 10%

[0077] BaO: 10%

[0078] Al 2 o 3 :4%

[0079] La 2 o 3 :5.5%

[0080] Dy 2 o 3 :0.5%

[0081] Accurately weigh P according to the above ratio 2 o 5 、K 2 CO 3 、BaCO 3 、Al 2 o 3 , La 2 o 3 and Dy 2 o 3 Wait for 500g of the corresponding raw materials of each oxide, put them in a mortar and grind them for 30 minutes to mix them evenly, and then melt them in a corundum crucible at 1250°C for 2 hours including steps of water removal, stirring and clarification. Then pour it into an iron mold preheated to 500°C for molding, and then quickly put it into a muffle furnace for precise gradient annealing at 500°C to obtain Dy 3+ Doped phosphate bulk core glass.

[0082] (2) Melting of phosphate bulk claddi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com