Aluminum alloy powder for additive manufacturing and preparation method and application thereof

A technology of additive manufacturing and aluminum alloy powder, which is applied in the direction of additive manufacturing and additive processing, can solve the problems that the strength and toughness cannot meet the use requirements, difficult processing, and affect the mechanical properties of formed parts, so as to improve the powder fluidity, Effect of improving wettability and improving spatial distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

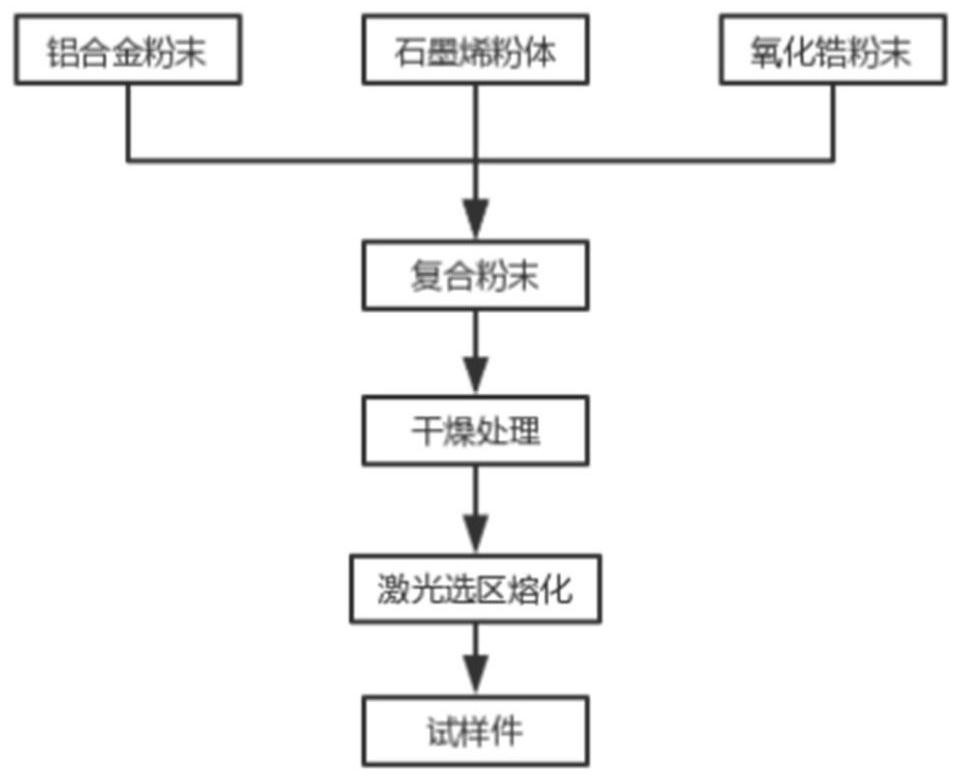

[0031] Such as figure 1 Shown, a kind of preparation method of aluminum alloy powder for additive manufacturing comprises the following steps:

[0032] S1, compounding aluminum alloy powder, graphene powder and zirconia powder to obtain a composite material;

[0033] Specifically, the aluminum alloy powder, the graphene powder and the zirconia powder are compounded by stirring with a homogenizer.

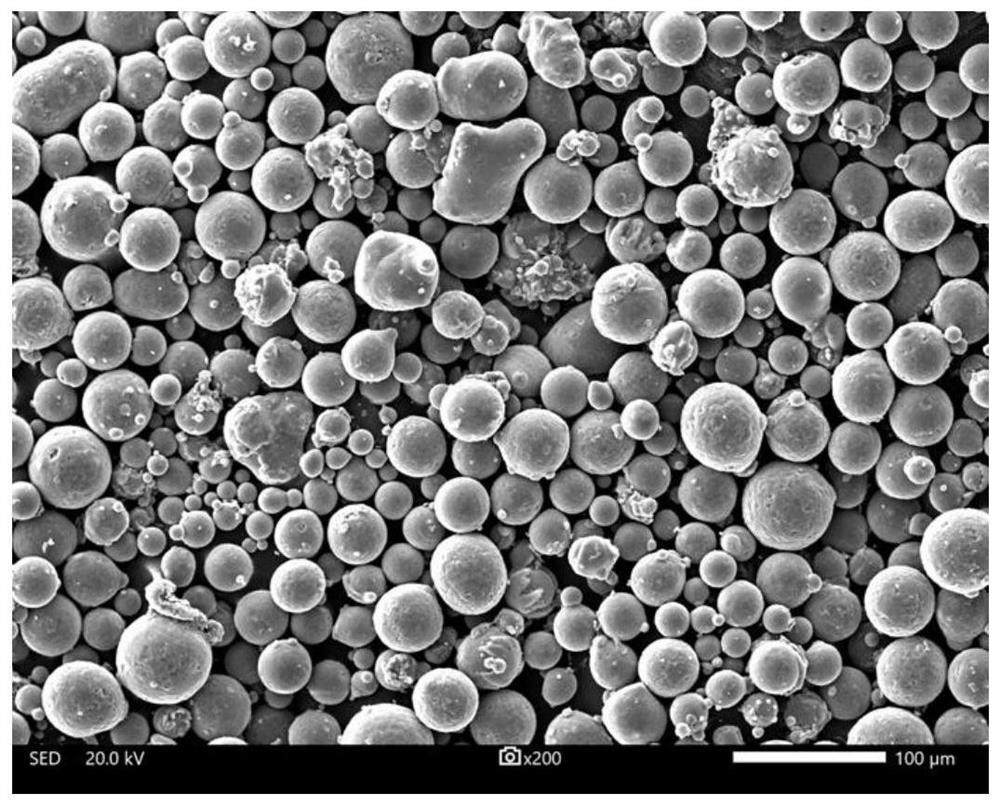

[0034] The mass ratio of aluminum alloy powder, graphene powder and zirconia powder is 98.2%-99.4%: 0.3%-0.9%: 0.3%-0.9%; during the composite process, the aluminum alloy powder, graphene powder Alcohol is added to the mixture of body and zirconia powder and stirred evenly; the speed of the homogenizer is adjusted to 1300-1800r / min, and the stirring time is 1-3min. Specifically, alcohol can infiltrate the composite material during the mixing process, and the use of alcohol can make the graphene powder, zirconia powder and aluminum alloy powder more uniformly dispersed, and can red...

Embodiment 1

[0043] (1) Weigh 994g of AlSi10Mg aluminum alloy powder, 3g of graphene powder and 3g of zirconia powder;

[0044] (2) Put the AlSi10Mg aluminum alloy powder, graphene powder and zirconia powder into the homogenizer, add an appropriate amount of alcohol, and then set the homogenizer speed to 1500r / s and the stirring time to 1min. Stir to obtain a mixed slurry;

[0045] (3) Dry the mixed slurry in a dryer for 3H, and set the drying temperature to 75°C; then dry the powder after drying in the dryer for 12H in a vacuum, and set the drying temperature to 110°C;

[0046] (4) The obtained composite powder is printed into shape by using laser selective melting (SLM) technology.

[0047] The microstructure of the formed part is as Figure 4 As shown, the two-phase nano-reinforced phase space of the formed material is evenly distributed. The strength test of the above-mentioned material shows that the tensile strength reaches 483Mpa, the yield strength reaches 330Mpa, and the elongat...

Embodiment 2

[0049] (1) Weigh 988g AlSi10Mg aluminum alloy powder, 6g graphene powder and 6g zirconia powder;

[0050] (2) Put the AlSi10Mg aluminum alloy powder, graphene powder and zirconia powder into the homogenizer, add an appropriate amount of alcohol, and then set the homogenizer speed to 1500r / s and the stirring time to 1min. Stir to obtain a mixed slurry;

[0051] (3) Dry the mixed slurry in a dryer for 3H, and set the drying temperature to 75°C; then dry the powder after drying in the dryer for 12H in a vacuum, and set the drying temperature to 110°C;

[0052] (4) The obtained composite powder is printed into shape by using laser selective melting (SLM) technology.

[0053] A strength test was carried out on the material obtained above, wherein the tensile strength reached 532Mpa, the yield strength reached 356Mpa, and the elongation was 7.6%. The tensile strength of the material in Example 2 was also improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com