Sb2Te3 phase change material based on oxygen doping, phase change memory and preparation method

A phase-change material and phase-change storage technology, applied in heat exchange materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problem of harsh selection conditions, unfavorable large-scale commercial production, structural characteristics and processes Parameter sensitivity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

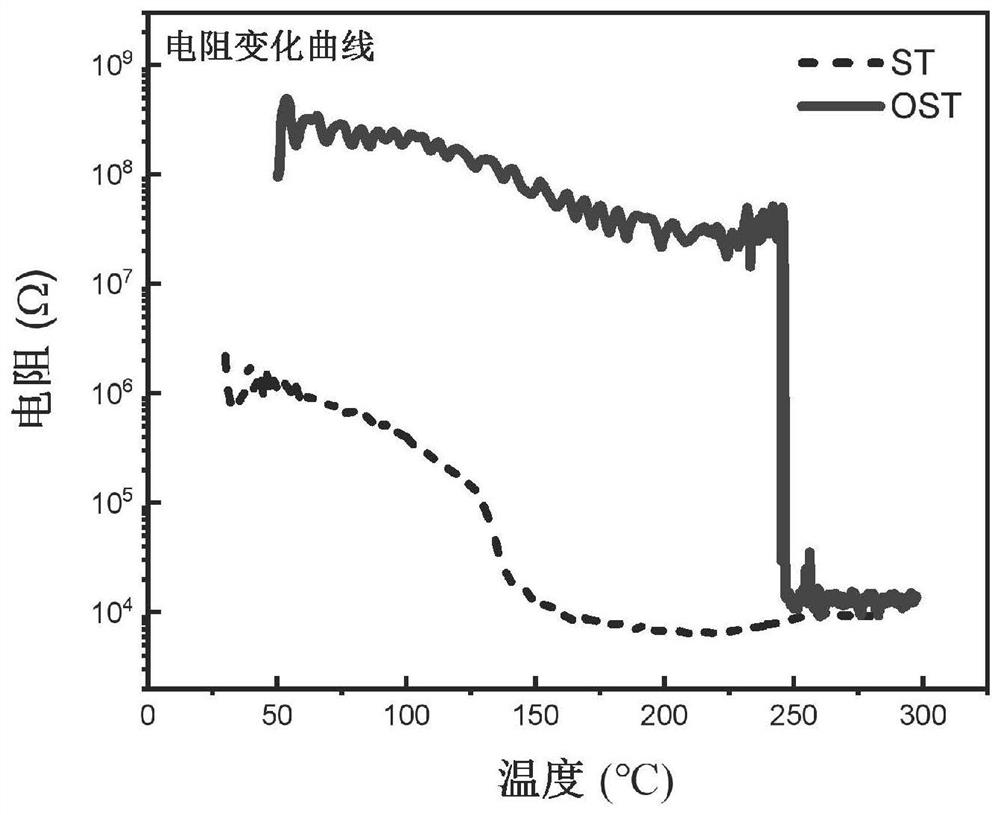

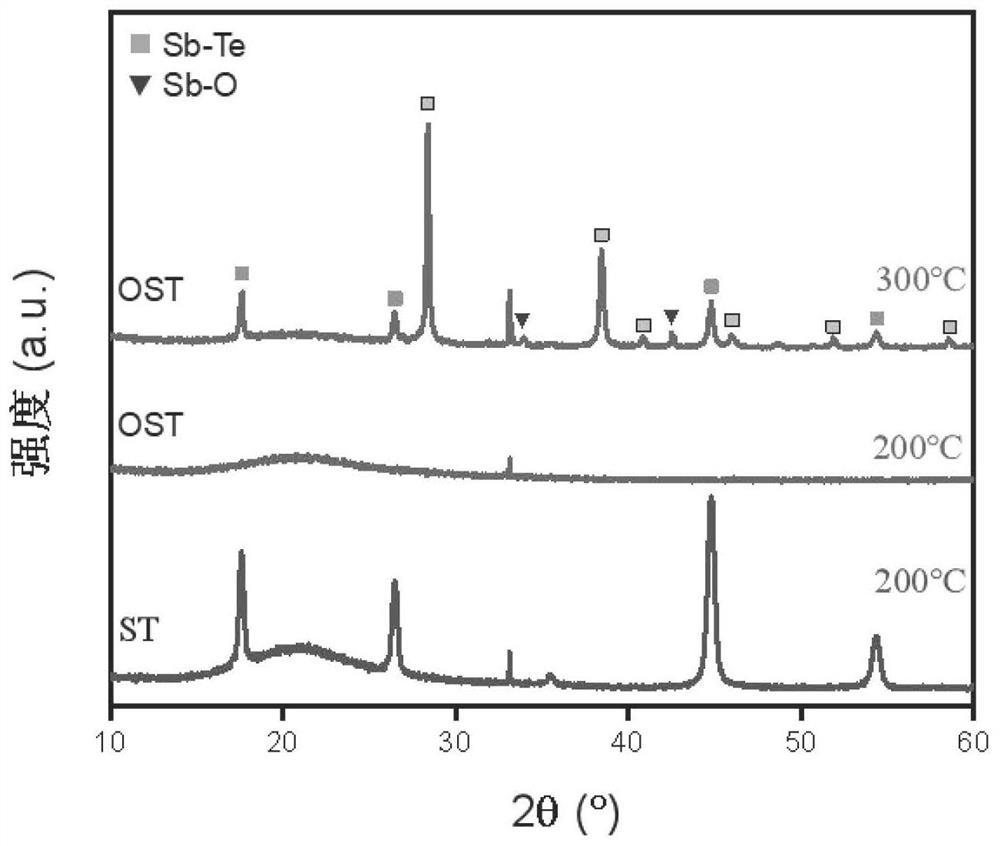

[0046] The O-Sb used for phase-change memory devices prepared in this example 2 Te 3 The general chemical formula of phase change memory thin film material is (ST) 1-x o x , where ST stands for Sb 2 Te 3 , x=0.1 in this embodiment.

[0047] O-Sb 2 Te 3 The phase-change memory thin film material is prepared by magnetron sputtering; during preparation, high-purity argon is introduced as the sputtering gas, and a small amount of oxygen is introduced to provide an aerobic atmosphere. The sputtering pressure is 0.5Pa, Sb 2 Te 3 The target adopts AC power supply, and the power supply power is 60W. Concrete preparation process comprises the following steps:

[0048] 1. Select SiO with a size of 1cm×1cm 2 / Si(100) substrate, clean the surface and back, remove dust particles, organic and inorganic impurities.

[0049] a) SiO 2 The / Si(100) substrate was placed in an acetone solution for 10 minutes with ultrasonic vibration of 40W power, and rinsed with deionized water.

[...

Embodiment 2

[0073] The O-Sb used for phase-change memory devices prepared in this example 2 Te 3 The general chemical formula of phase change memory thin film material is (ST) 1-x o x , where ST stands for Sb 2 Te 3 , x=0.1 in this embodiment.

[0074] O-Sb 2 Te 3 The phase change memory thin film material is prepared by magnetron sputtering. During the preparation, high-purity argon gas was introduced as the sputtering gas, and a small amount of oxygen was introduced to provide an aerobic atmosphere. The sputtering pressure was 0.5Pa, and Sb 2 Te 3 The target adopts AC power supply, and the power supply power is 60W. Concrete preparation process comprises the following steps:

[0075] 1. Select SiO with a size of 1cm×1cm 2 / Si(100) substrate, clean the surface and back, remove dust particles, organic and inorganic impurities.

[0076] a) SiO 2 The / Si(100) substrate was placed in an acetone solution for 10 minutes with ultrasonic vibration of 40W power, and rinsed with deion...

Embodiment 3

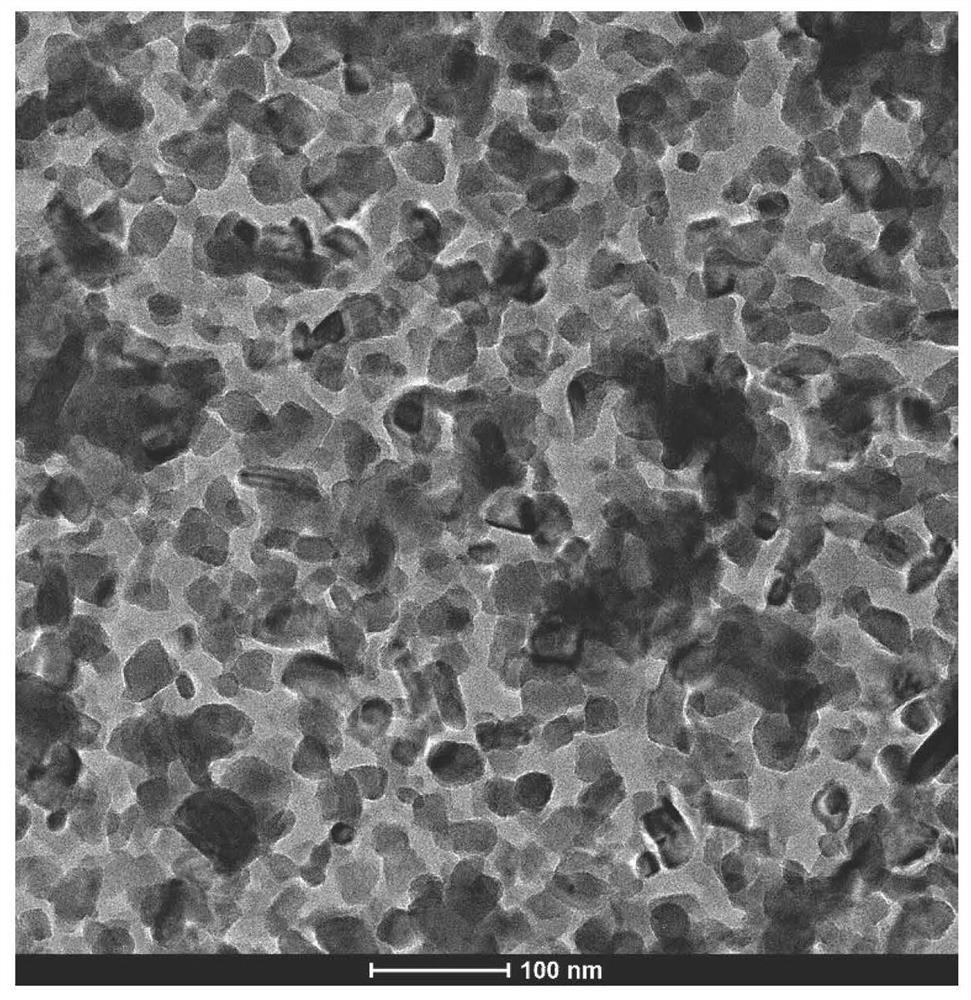

[0090] This example uses the Materials Studio software to add Sb with a concentration of 5%, 10% and 20% to the O element respectively. 2 Te 3 Modeling of phase change memory thin film materials, randomization of three models by first principles, simulation of melting and quenching process to obtain OST phase change memory with O element doping concentrations of 5%, 10% and 20% respectively Amorphous model for thin film materials, the results are as Figure 7 shown. Simplified "shell-core" structure O-Sb using Materials Studio software 2 Te 3 and pure Sb 2 Te 3 Modeling, using first-principles to simulate the "shell-core" structure O-Sb at different temperatures 2 Te 3 model and pure Sb 2 Te 3 Atomic motion and the "shell-core" structure O-Sb at the same temperature 2 Te 3 In the model, the movement of atoms in the middle area and the atoms in the area close to the shell is formed into an intuitive image through data processing. Figure 8 is the influence of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com