Sound-absorbing and heat-insulating automotive interior material and preparation method thereof

A technology for automobile interior decoration and hexagonal boron nitride is applied in the field of sound-absorbing and heat-insulating automobile interior decoration materials and their preparation, and can solve the problems of hidden dangers in circuit safety, aggravated combustion, poor sound insulation effect and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

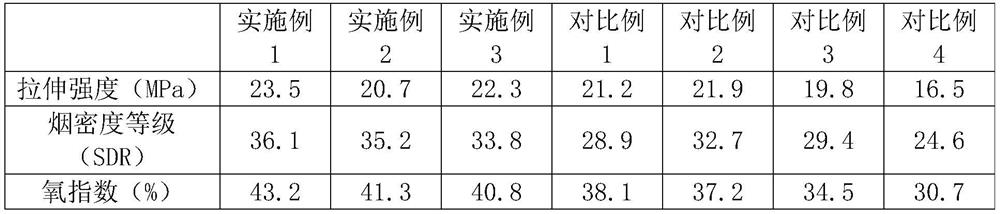

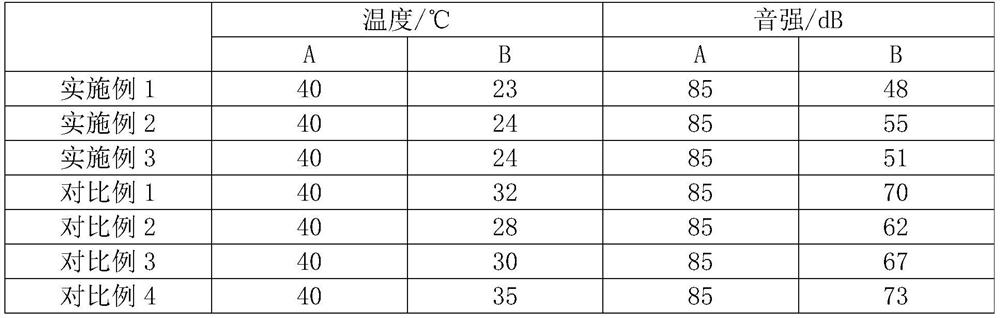

Examples

Embodiment 1

[0035] A sound-absorbing and heat-insulating automotive interior material, in parts by mass, comprising the following components:

[0036] 40 parts of polyurethane resin, 50 parts of EPDM rubber, 30 parts of epoxy modified silicone resin, 5 parts of polypropylene, 15 parts of hexagonal boron nitride, 23 parts of porous powder quartz, 24 parts of inorganic flame retardant, carbon nano Cone 7 parts, plasticizer 2 parts and deionized water 100 parts.

[0037] In this embodiment, the mass ratio of epoxy resin to silicone resin in the epoxy-modified silicone resin is 1:3.

[0038] The mass ratio of the phosphorus-based flame retardant to the nitrogen-based flame retardant in the inorganic flame retardant is 1:5.

[0039] The plasticizer is an equal mass mixture of alkyl sulfonate and epoxy compound.

[0040] The carbon nanocones are SH-PEG-COOH modified carbon nanocones.

[0041] The preparation method of the above-mentioned sound-absorbing and heat-insulating automotive interio...

Embodiment 2

[0048] A sound-absorbing and heat-insulating automotive interior material, in parts by mass, comprising the following components:

[0049] 50 parts of polyurethane resin, 40 parts of EPDM rubber, 40 parts of epoxy modified silicone resin, 4 parts of polypropylene, 20 parts of hexagonal boron nitride, 20 parts of porous powder quartz, 26 parts of inorganic flame retardant, carbon nano Cone 5 parts, plasticizer 3 parts and deionized water 80 parts.

[0050] In this embodiment, the mass ratio of epoxy resin to silicone resin in the epoxy-modified silicone resin is 1:4.

[0051] The mass ratio of the phosphorus-based flame retardant to the nitrogen-based flame retardant in the inorganic flame retardant is 1:4.

[0052] The plasticizer is phosphoric acid ester.

[0053] The carbon nanocones are SH-PEG-COOH modified carbon nanocones.

[0054] The preparation method of the above-mentioned sound-absorbing and heat-insulating automotive interior material comprises the following step...

Embodiment 3

[0061] A sound-absorbing and heat-insulating automotive interior material, in parts by mass, comprising the following components:

[0062] 30 parts of polyurethane resin, 60 parts of EPDM rubber, 20 parts of epoxy modified silicone resin, 6 parts of polypropylene, 10 parts of hexagonal boron nitride, 25 parts of porous powder quartz, 22 parts of inorganic flame retardant, carbon nano Cone 8 parts, plasticizer 1 part and deionized water 120 parts.

[0063] In this embodiment, the mass ratio of epoxy resin to silicone resin in the epoxy-modified silicone resin is 1:2.

[0064] The mass ratio of the phosphorus-based flame retardant to the nitrogen-based flame retardant in the inorganic flame retardant is 1:6.

[0065] The plasticizer is an equal mass mixture of phosphate ester and epoxy compound.

[0066] The carbon nanocones are SH-PEG-COOH modified carbon nanocones.

[0067] The preparation method of the above-mentioned sound-absorbing and heat-insulating automotive interior...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com