Diquat dichloride synthesis method and device

A synthesis method and technology of diquat, applied in the direction of organic chemistry, etc., can solve the problems of complex process, low production efficiency, cumbersome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

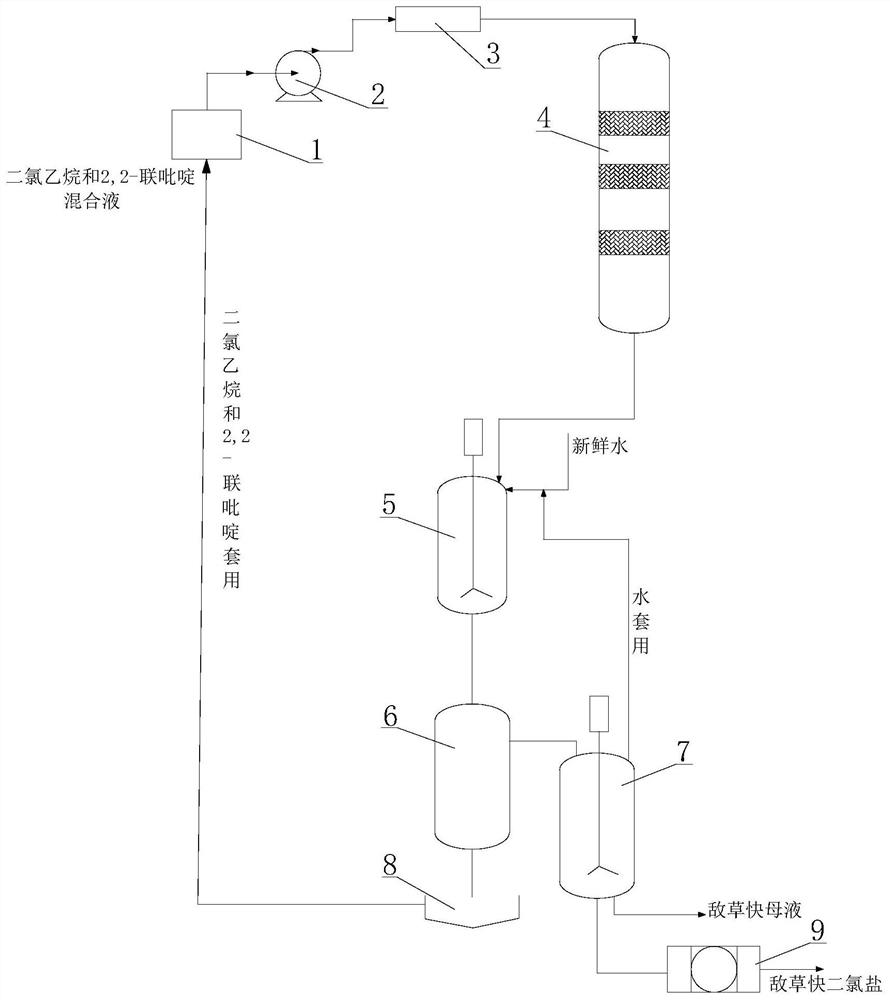

[0033] refer to figure 1 , a synthetic method of diquat dichloride, comprising the steps of:

[0034] Step 1: Catalyst Activation

[0035] Put the catalyst into the fixed-bed reactor 4, activate it for 4-6h at a temperature of 300-550°C and a nitrogen flow rate of 50-150ml / min, then lower the temperature to the reaction temperature, and adjust the pressure to the reaction pressure;

[0036] Step 2: Mix the ingredients

[0037] Add dichloroethane and 2,2-bipyridine into mixer 1 and mix, and the temperature of mixer 1 is between 50-100°C;

[0038] Step 3: Cyclization Reaction

[0039] The mixed liquid in the mixer 1 is pumped into the gasification chamber 3 at a certain speed by the centrifugal pump 2 for gasification. After gasification, the gas enters the fixed bed reactor 4 from the top of the fixed bed to react, and the fixed bed reactor 4 then enters the condensation pipe 5 Condensate, water is continuously entered into the condenser pipe 5 to extract diquat dichloride,...

Embodiment 1

[0043] CuO / γ-Al 2 o 3 (the content of CuO is 1%) catalyzer is packed in the fixed-bed reactor, at temperature 300 ℃, activation 4h under the condition of nitrogen flow rate 100ml / min, cool down to 140 ℃, reaction pressure is 1MPa, raw material is 0.5ml / min at speed min into the reactor to react, and then cooled, extracted, separated, distilled and filtered to obtain diquat dichloride product with a yield of 93.5%.

Embodiment 2

[0045] CuO / γ-Al 2 o 3(the content of CuO is 1%) catalyzer is packed in the fixed-bed reactor, at temperature 550 ℃, activation 6h under the condition of nitrogen flow velocity 150ml / min, cool down to 300 ℃, reaction pressure is 3MPa, raw material is 2.5ml / min at speed min into the reactor for reaction, and then cooled, extracted, separated, distilled and filtered to obtain diquat dichloride product with a yield of 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com