Biomass oxidative cracking catalyst based on modified H-Beta molecular sieve and preparation method and application thereof

A technology of oxidative cracking and catalysts, which is applied in molecular sieve catalysts, physical/chemical process catalysts, oxidation reaction preparation, etc., and can solve the problems of low product selectivity and non-reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

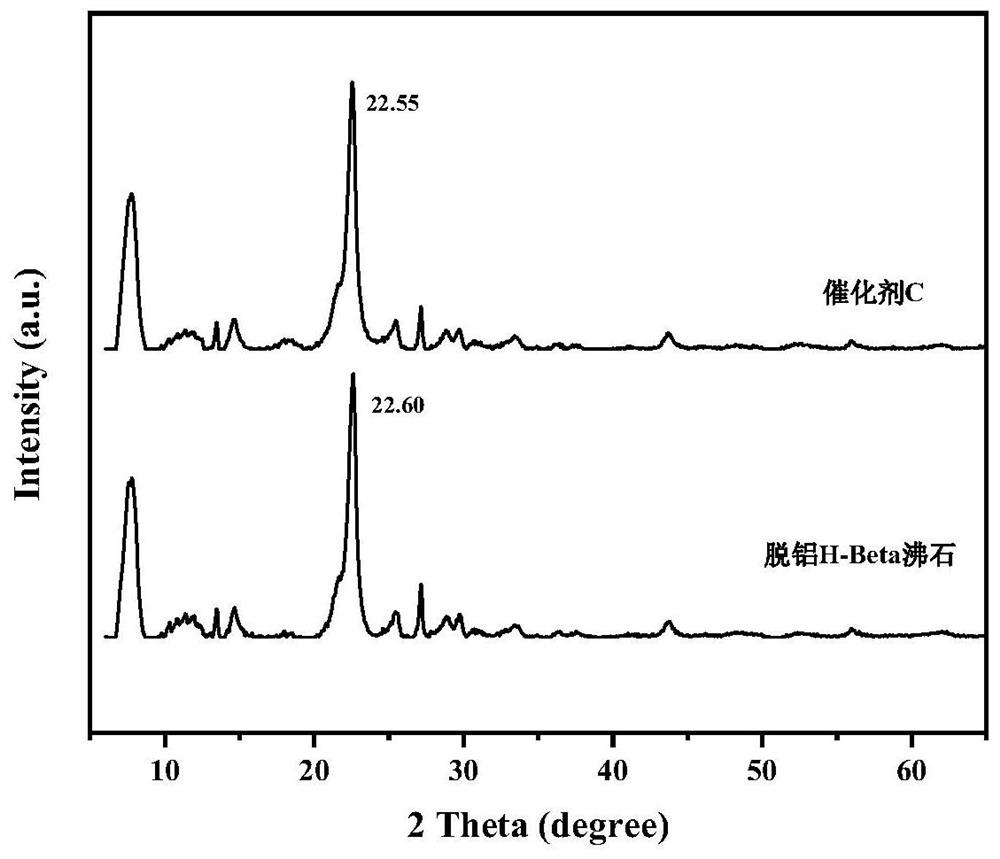

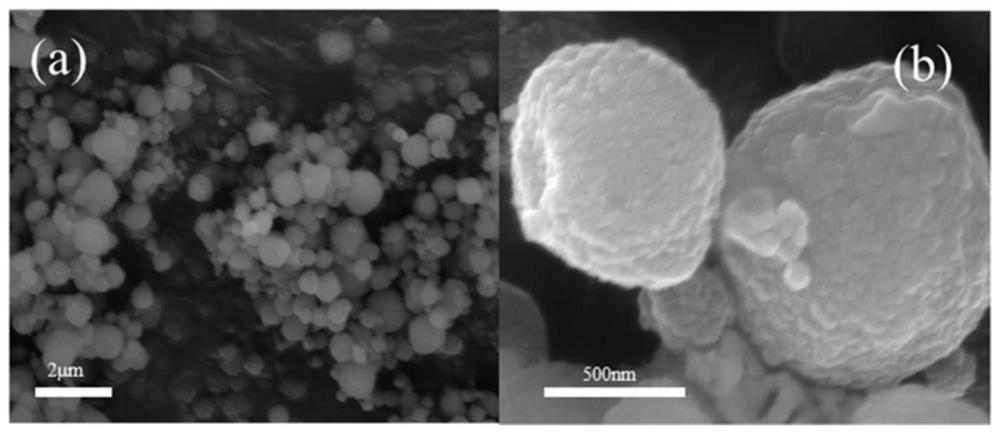

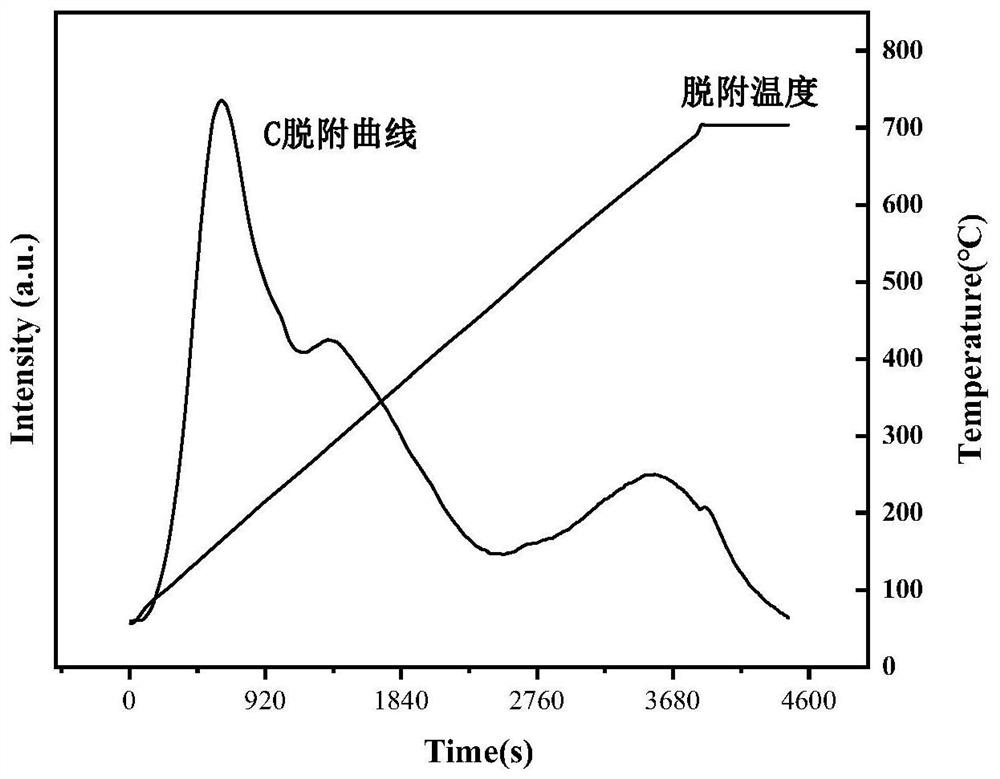

[0038] A kind of preparation method of the biomass oxidative cracking catalyst based on modified H-Beta molecular sieve of the present invention comprises the following steps:

[0039] Dissolve the soluble active component precursor in deionized water to obtain the active component solution, then disperse the dealuminated H-Beta carrier in the active component solution for stirring and impregnation, and obtain a heterogeneous phase after rotary evaporation, drying and roasting supported catalyst.

[0040] Among them, the soluble active component precursor is copper nitrate, copper sulfate, copper chloride, zinc nitrate, zinc sulfate, zinc chloride, ferric nitrate, ferrous nitrate, ferric sulfate, ferrous sulfate, ferric chloride, ferrous chloride One or more of iron, silver nitrate, cobalt chloride, cobalt sulfate, cobalt nitrate and tetrachloroauric acid.

[0041] The further improvement of the present invention is that the mass ratio of the active component precursor to the...

Embodiment 1

[0054] The active component precursor was dissolved in 30mL deionized water to obtain the active component solution, and then 4g of dealuminated H-Beta carrier was dispersed in the active component solution, and immersed for 12h under magnetic stirring at 400r / min, and then The obtained suspension was evaporated to dryness on a rotary evaporator at a temperature of 60°C and a pressure of -0.09MPa at a speed of 40r / min, and then the obtained solid was dried in an oven at 110°C for 12h. After drying, it was placed in a muffle furnace from room temperature to 450°C at a rate of 2°C / min, and calcined for 6 hours to obtain a supported catalyst, denoted as A. Among them, the active component precursor is Cu(NO 3 ) 2 ·3H 2 O, the mass ratio of the active component precursor and the dealuminated H-Beta carrier is 5:100;

Embodiment 2

[0056] The difference from Example 1 is that the mass ratio of the active component precursor to the dealuminated H-Beta carrier is 10:100; the catalyst prepared in this example is designated as B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com