Monatomic catalyst doped with rare earth element and used for hydrogenation of organic hydrogen storage medium and preparation method of monatomic catalyst

A technology of rare earth elements and catalysts, applied in the field of catalytic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

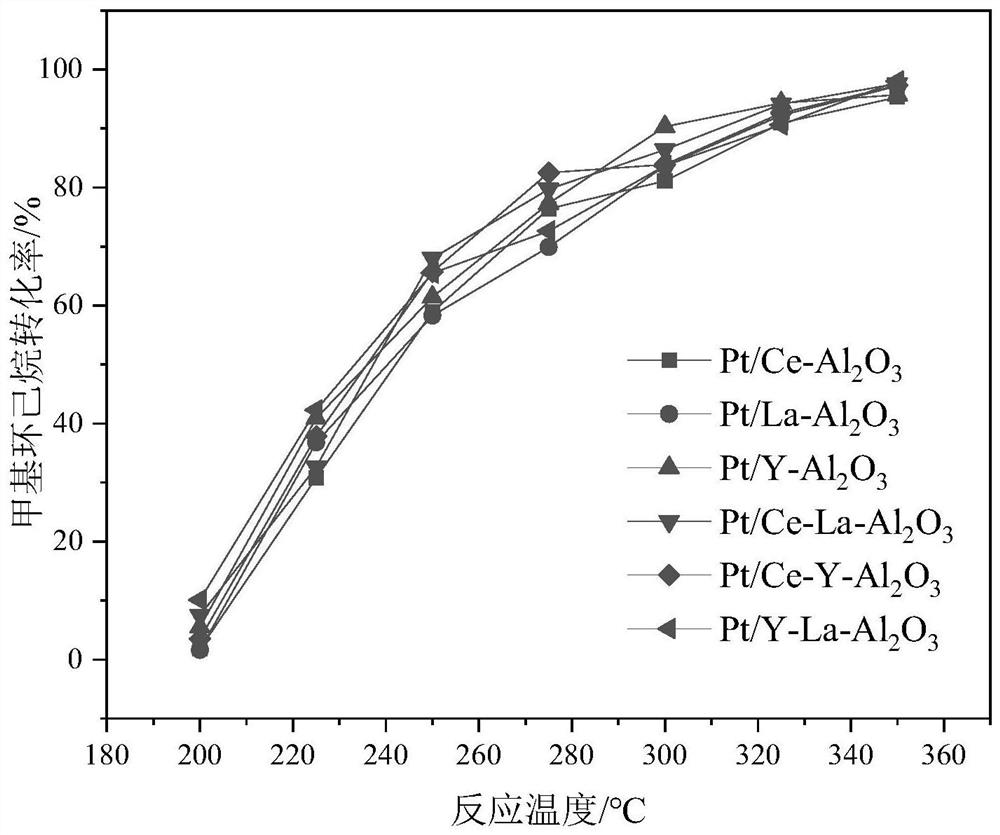

Embodiment 1

[0034] Weigh 18.75g of Al(NO 3 ) 3 9H 2 O and 0.868g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in 500 mL of deionized water, stirred at room temperature at a speed of 300 r / min for 10 min, then 2 mL of polyethylene glycol 400 was added as a dispersant, and stirred for 15 min to obtain a mixed solution. At the same time, ammonia water with a mass fraction of 5 wt% was prepared, ammonia water was added dropwise to the mixed solution under stirring, and the pH of the solution was adjusted to 9.0, and then the stirring reaction was kept for 40 minutes, and then the stirring was turned off. The precipitate was separated by vacuum filtration, and the obtained precipitate was washed with deionized water for 3 times, then placed in a constant temperature 90°C water bath for 4 hours to crystallize, after the crystallization was completed, it was washed with absolute ethanol for 3 times, and then placed in a 100°C oven Dry for 10 hours to obtain a catalyst carrier precursor. The cataly...

Embodiment 2

[0039] Weigh 18.75g of Al(NO 3 ) 3 9H 2 O and 0.866g of La(NO 3 ) 3 ·6H 2 O was dissolved in 500 mL of deionized water, stirred at room temperature at a speed of 300 r / min for 10 min, then 2 mL of polyethylene glycol 400 was added as a dispersant, and stirred for 15 min to obtain a mixed solution. At the same time, ammonia water with a mass fraction of 5 wt% was prepared, ammonia water was added dropwise to the mixed solution under stirring, and the pH of the solution was adjusted to 9.0, and then the stirring reaction was kept for 40 minutes, and then the stirring was turned off. The precipitate was separated by vacuum filtration, and the obtained precipitate was washed with deionized water for 3 times, then placed in a constant temperature 90°C water bath for 4 hours to crystallize, after the crystallization was completed, it was washed with absolute ethanol for 3 times, and then placed in a 100°C oven Dry for 10 hours to obtain a catalyst carrier precursor. The cataly...

Embodiment 3

[0044] Weigh 18.75g of Al(NO 3 ) 3 9H 2 O and 0.766g of Y (NO 3 ) 3 ·6H 2 O was dissolved in 500 mL of deionized water, stirred at room temperature at a speed of 300 r / min for 10 min, then 2 mL of polyethylene glycol 400 was added as a dispersant, and stirred for 15 min to obtain a mixed solution. At the same time, ammonia water with a mass fraction of 5 wt% was prepared, ammonia water was added dropwise to the mixed solution under stirring, and the pH of the solution was adjusted to 9.0, and then the stirring reaction was kept for 40 minutes, and then the stirring was turned off. The precipitate was separated by vacuum filtration, and the obtained precipitate was washed with deionized water for 3 times, then placed in a constant temperature 90°C water bath for 4 hours to crystallize, after the crystallization was completed, it was washed with absolute ethanol for 3 times, and then placed in a 100°C oven Dry for 10 hours to obtain a catalyst carrier precursor. The cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com