Adsorbing material for removing carbonyl sulfide by carbon material loaded ionic liquid and application of adsorbing material

An ionic liquid and adsorption material technology, which is applied in the field of adsorption and separation of carbonyl sulfide gas, can solve the problems of low gas-liquid mass transfer efficiency, cumbersome preparation process, and difficult industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

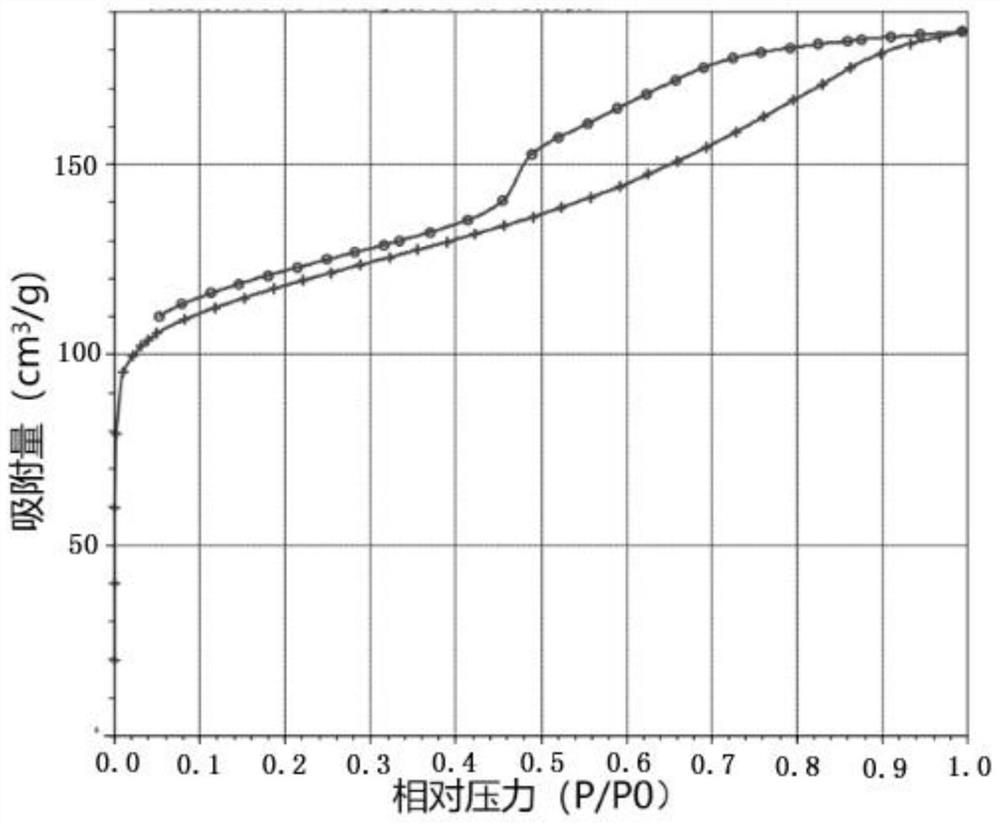

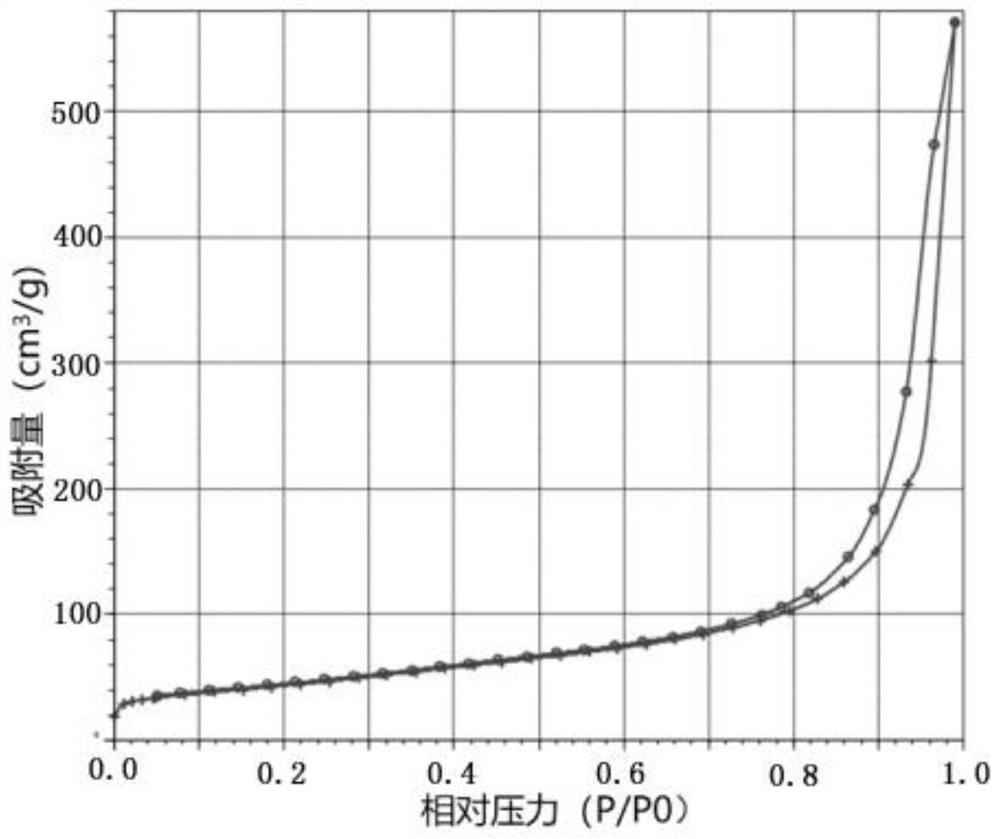

Image

Examples

Embodiment 1

[0032] Example 1: A carbonyl sulfide material supported by an ionic liquid, the preparation steps of which are as follows:

[0033] (1) Synthesis of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid

[0034] The invention adopts a two-step method to synthesize the 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid, and the first step is to synthesize the 1-ethyl-3-methylimidazolium bromide ionic liquid. First take by weighing N-methylimidazole and bromoethane according to molar ratio 1:1.1, the N-methylimidazole that takes is placed in reactor, in N 2 Under protection, the water bath was heated to 40°C, and then the weighed ethyl bromide was slowly added to the reactor drop by drop at a rate of 1 drop / (2~3s) with a constant pressure funnel, and the reaction was stirred and refluxed for 8 hours, and the reactant gradually became into a white solid; after the reaction is completed, it is cooled to room temperature, and the solid product is washed and purified w...

Embodiment 2

[0038] Embodiment 2: A carbonyl sulfide material loaded with ionic liquid, its preparation steps are as follows:

[0039] (1) Synthesis of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid

[0040] The synthesis steps of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid were repeated in Example 1.

[0041] (2) Activated carbon supported 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid

[0042] First, the granular activated carbon (blue carbon, particle size 0.5-1.0 cm) was thoroughly washed with water until the pH was neutral, and then dried for later use. 1.0 g of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid was added to 20 mL of deionized water, after ultrasonic mixing for 6 min, 20 g of treated activated carbon was added, and then at room temperature, Stir and impregnate for 10 h, and finally place the mixture in a vacuum oven, dry at 70 °C for 6 h, and place the obtained adsorbent in N 2 Store in an atmosphere desiccator.

Embodiment 3

[0043] Embodiment 3: A carbonyl sulfide removal material supported by an activated carbon-supported ionic liquid, the preparation steps of which are as follows:

[0044] (1) Synthesis of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid

[0045] The synthesis steps of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid were repeated in Example 1.

[0046] (2) Activated carbon supported 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid

[0047] First, the granular activated carbon (blue carbon, particle size 0.5-1.0 cm) was thoroughly washed with water until the pH was neutral, and then dried for later use. 2.0 g of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid was added to 20 mL of deionized water, after ultrasonic mixing for 8 min, 20 g of treated activated carbon was added, and then at room temperature, Stir and impregnate for 12 h, and finally place the mixture in a vacuum oven, dry at 70 °C for 8 h, and place the obtained adsorbent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com