Preparation method of inorganic nanomaterial, inorganic nanomaterial and light-emitting diode

A technology of inorganic nanomaterials and light-emitting diodes, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as surface defects of zinc oxide nanomaterials, reduce irreversible effects, balance electron transfer rates, and improve quantum The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

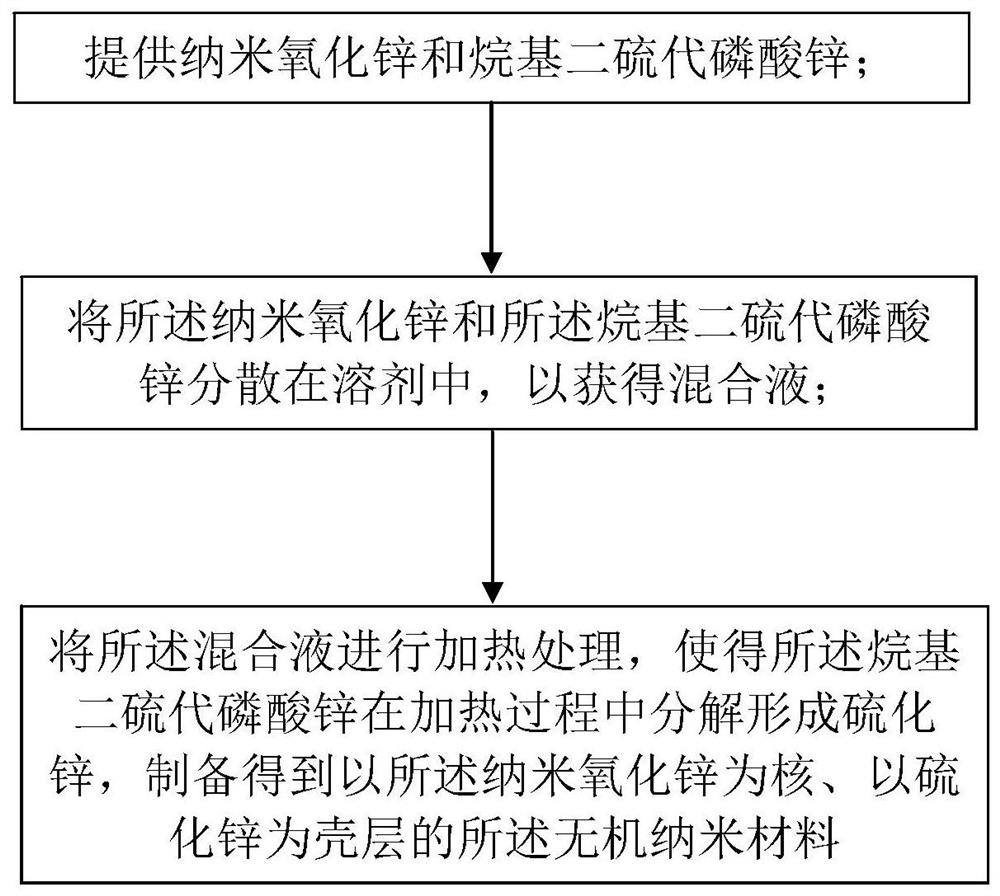

[0023] A preparation method of inorganic nanomaterials, such as figure 1 shown, including the following steps:

[0024] S01. Provide nano zinc oxide and zinc alkyl dithiophosphate;

[0025] S02, disperse the nano zinc oxide and the zinc alkyl dithiophosphate in a solvent to obtain a mixed solution;

[0026] S03, heating the mixed solution, so that the zinc alkyl dithiophosphate is decomposed to form zinc sulfide during the heating process, and the nano-zinc oxide is used as the core and the zinc sulfide is used as the shell layer. Inorganic Nanomaterials.

[0027] Specifically, in step S01, the zinc alkyl dithiophosphate can be decomposed under heating to form zinc sulfide, which can be used as a precursor of zinc sulfide to prepare the nano-zinc oxide as the core and the zinc sulfide as the shell At the same time, the alkyl dithiophosphate zinc contains a bidentate ligand of the alkyl dithiophosphate ion, and the alkyl dithiophosphate ion can simultaneously interact with t...

Embodiment 1

[0061] This embodiment prepares a quantum dot light-emitting diode, which specifically includes the following steps:

[0062] 1. Preparation of inorganic nanomaterials with the nano-zinc oxide as the core and zinc sulfide as the shell

[0063] Weigh 15 mL of the nano-zinc oxide solution with a concentration of 25 mg / mL prepared by the low temperature solution method, add 72 mg of zinc diisooctyl dithiophosphate, and mix well to obtain a mixed solution; react the mixed solution at 250 ° C for 1 h, After the reaction is completed, precipitating agent ethyl acetate is added to carry out the substrate, and then centrifugal separation is performed to obtain the inorganic nanomaterial ZnO / ZnS based on the surface modification of diisooctyl dithiophosphate ion.

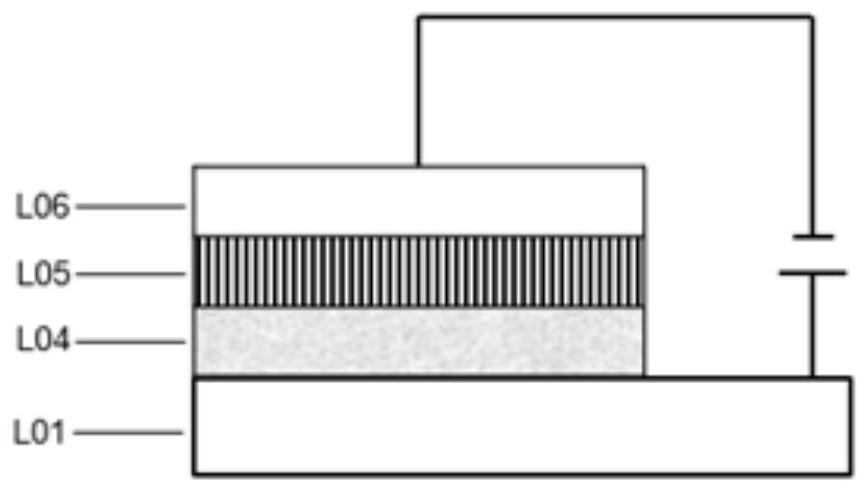

[0064] 2. Preparation of quantum dot light-emitting diodes

[0065] An anode, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer and a cathode are sequentially de...

Embodiment 2

[0067] This embodiment prepares a quantum dot light-emitting diode, which specifically includes the following steps:

[0068] 1. Preparation of inorganic nanomaterials with the nano-zinc oxide as the core and zinc sulfide as the shell

[0069] Weigh 15 mL of the nano-zinc oxide solution with a concentration of 25 mg / mL prepared by the low temperature solution method, add 72 mg of zinc diisooctyl dithiophosphate, and mix well to obtain a mixed solution; react the mixed solution at 250 ° C for 1 h, After the reaction is completed, precipitating agent ethyl acetate is added to carry out the substrate, and then centrifugal separation is performed to obtain the inorganic nanomaterial ZnO / ZnS based on the surface modification of diisooctyl dithiophosphate ion.

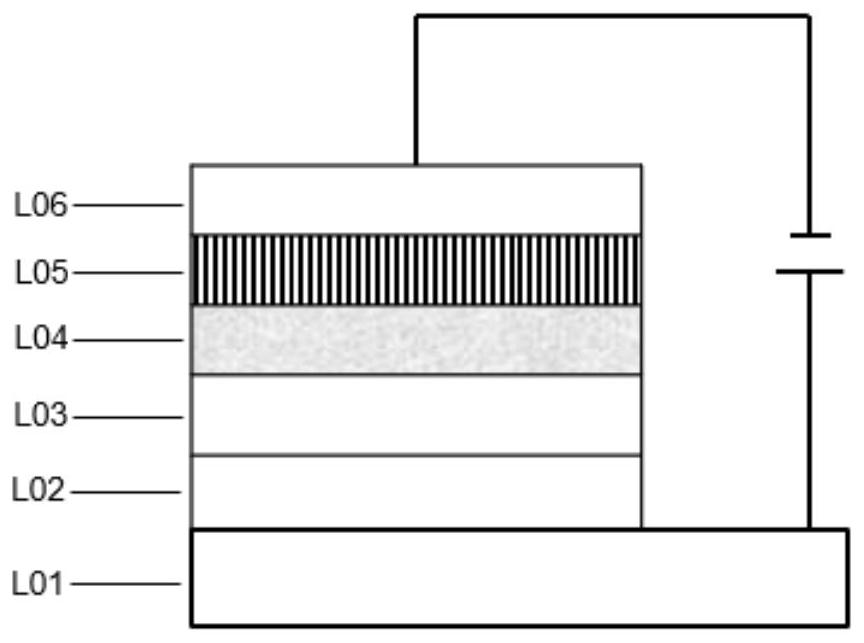

[0070] 2. Preparation of quantum dot light-emitting diodes

[0071] An anode, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer and a cathode are sequentially de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com