Temperature programming-infrared spectroscopy combined device and application thereof in catalyst preparation

A temperature-programmed, combined technology, applied in catalyst activation/preparation, physical/chemical process catalysts, measurement devices, etc., can solve the problems of inability to realize qualitative research on catalyst preparation, and inability to provide physical and chemical changes of solid catalyst surface reactants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

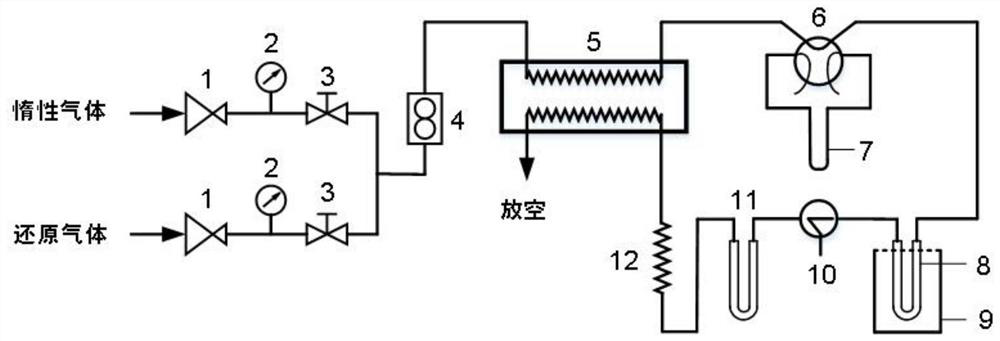

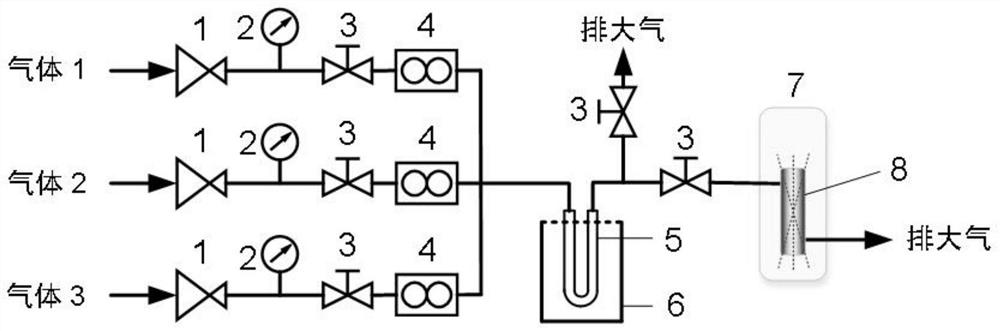

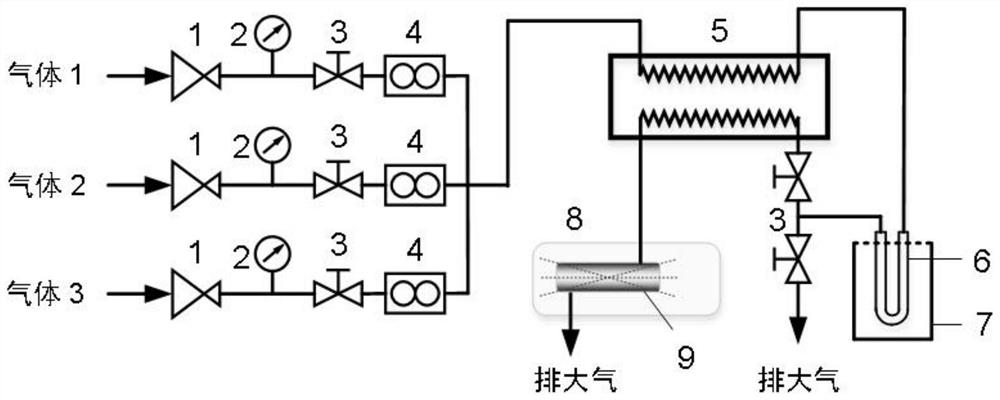

[0034] (1) Use the infrared system alone: the temperature-programmed-infrared combined device includes a temperature-programmed reaction system and a detection system ( Figure 2a ). The temperature-programmed reaction system includes: more than two gas paths, each gas path is equipped with a pressure reducing valve 1, a pressure gauge 2, a stop valve 3, a mass flow meter 4, and the gas paths are in parallel; the mass flow meter outlet and the reaction tube 5 inlet Connection, the reaction tube is heated by the heating furnace 6, and the outlet of the reaction tube is divided into two channels, one leads to the atmosphere, and the other leads to the detection system; the gas channel entering the detection system is connected with the inlet of the gas sample pool 8 of the infrared spectrometer 7, and the gas passes through the infrared After spectral detection and recording, it flows out from the outlet of the gas sample cell and leads to the atmosphere.

[0035] (2) Tempera...

Embodiment 2

[0038] Preparation of Ni 2 Phosphate precursors for P catalysts

[0039] 6.6g of nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) was dissolved in 15 mL of deionized water, and 3 g of diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) was dissolved in 10 mL of deionized water, and the diammonium hydrogen phosphate aqueous solution was added dropwise to the continuously stirred (200 rpm) nickel nitrate aqueous solution at room temperature, and the stirring was continued for 30 min after the dropwise addition. The mixture was placed on the electric furnace, and the water was evaporated by stirring with a glass rod while heating. When a large amount of water was evaporated, it was transferred to a blast drying oven at 120°C for drying for 12 hours. The dried samples were ground and pulverized, then transferred to a muffle furnace and calcined at 500 °C for 3 h in an air atmosphere to obtain Ni. 2 Phosphate precursor for P catalysts.

Embodiment 3

[0044] Preparation of Phosphate Precursors for MoP Catalysts

[0045] 4 g of ammonium molybdate ((NH 4 ) 6 Mo 7 O 24 ·4H 2 O) was dissolved in 15 mL of deionized water, and 3 g of diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) was dissolved in 10 mL of deionized water, the diammonium hydrogen phosphate aqueous solution was added dropwise to the (200 rpm) ammonium molybdate aqueous solution continuously stirred at room temperature, and the stirring was continued for 30 min after the dropwise addition. The mixture was placed on the electric furnace and heated while stirring with a glass rod to evaporate the water. When a large amount of water was evaporated, it was transferred to a blast drying oven for drying at 120°C for 12 hours. The dried samples were ground and pulverized, and then transferred to a muffle furnace for calcination at 500 °C in an air atmosphere for 3 h to obtain the phosphate precursor of the MoP catalyst.

[0046] Preparation of MoP catalysts from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com