Permeability coefficient and temperature real-time monitoring device and monitoring method in sand solidification process

A permeability coefficient, real-time monitoring technology, applied in the direction of measuring devices, instruments, etc., can solve the problem that the permeability coefficient and temperature change with time cannot be monitored in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, innovative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

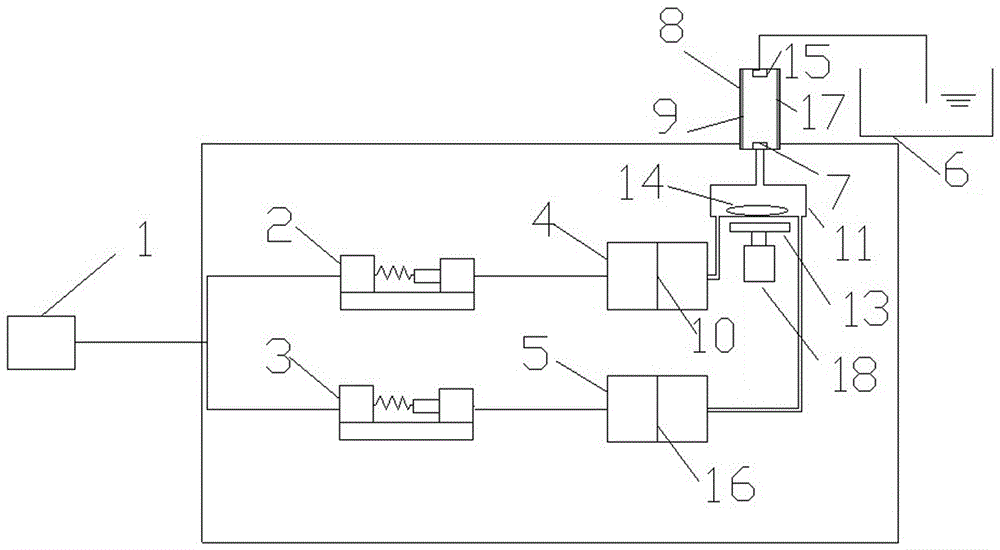

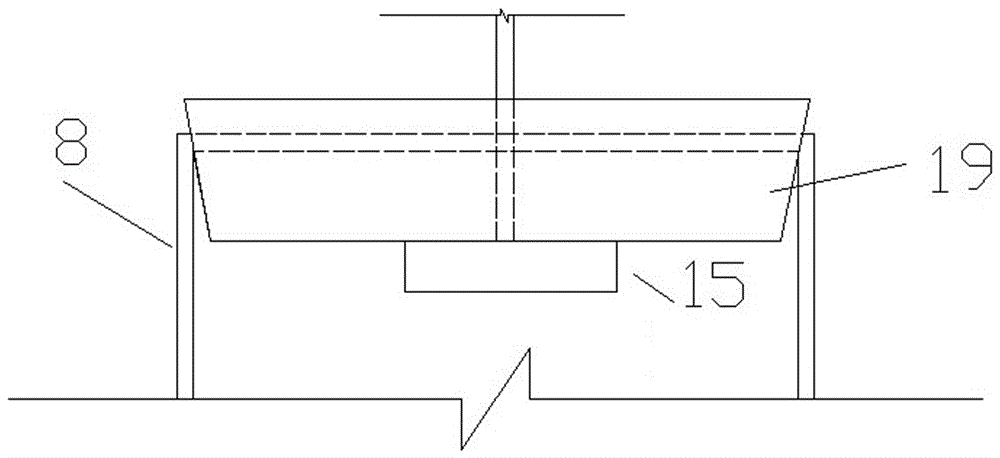

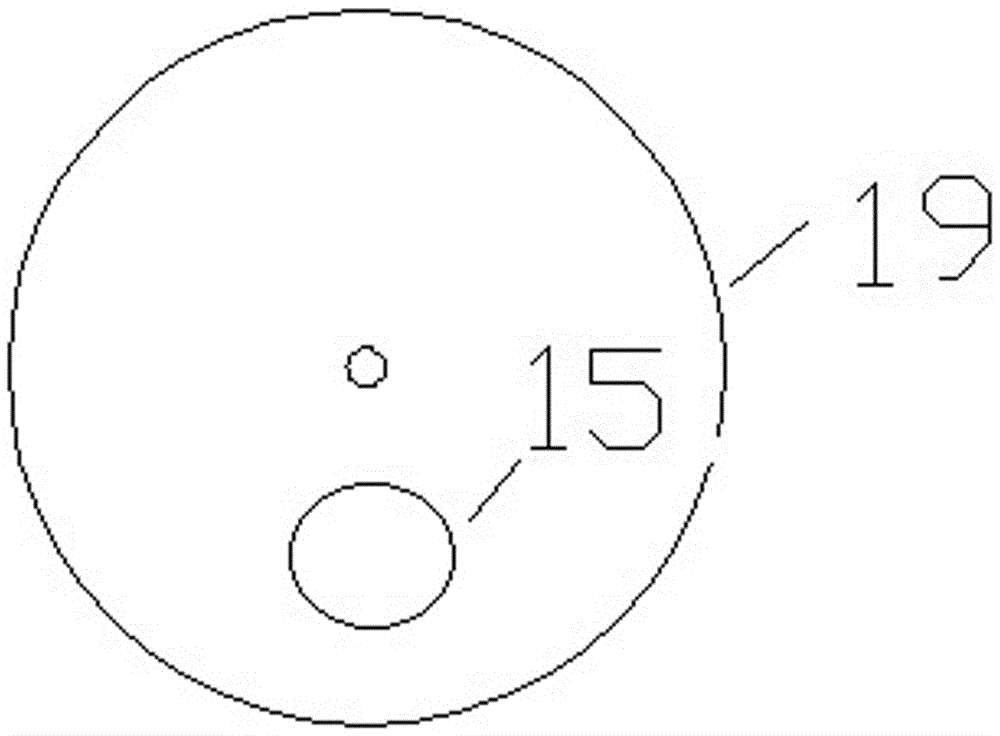

[0034] Such as Figure 1-4 As shown, the data acquisition and control system 1 is respectively connected to the water glass solution pressure controller 2, the calcium chloride solution pressure controller 3, the first distributed optical fiber 9, the second distributed optical fiber 17, the first pore water pressure Meter 7 and the second pore water pressure gauge 15; described water glass solution pressure controller 2 links to each other with water glass solution pressure transfer device 4, and described calcium chloride solution pressure controller 3 links to each other with calcium chloride solution pressure transfer device 5 The water glass solution pressure transmission device 4 is divided into two chambers by the first isolation rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com