Lithium ion battery composite gel diaphragm as well as preparation method and application thereof

A lithium ion battery and composite gel technology, which is applied in the field of lithium ion battery composite gel separator and its preparation, can solve the problems of high porosity of the separator, and achieves the improvement of safety performance, excellent liquid absorption performance and high tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

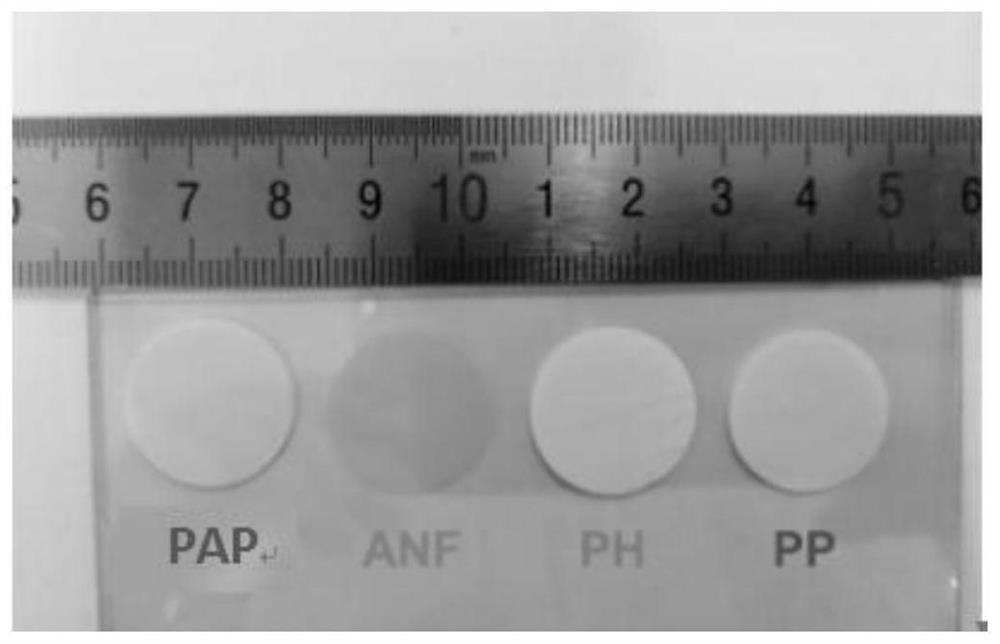

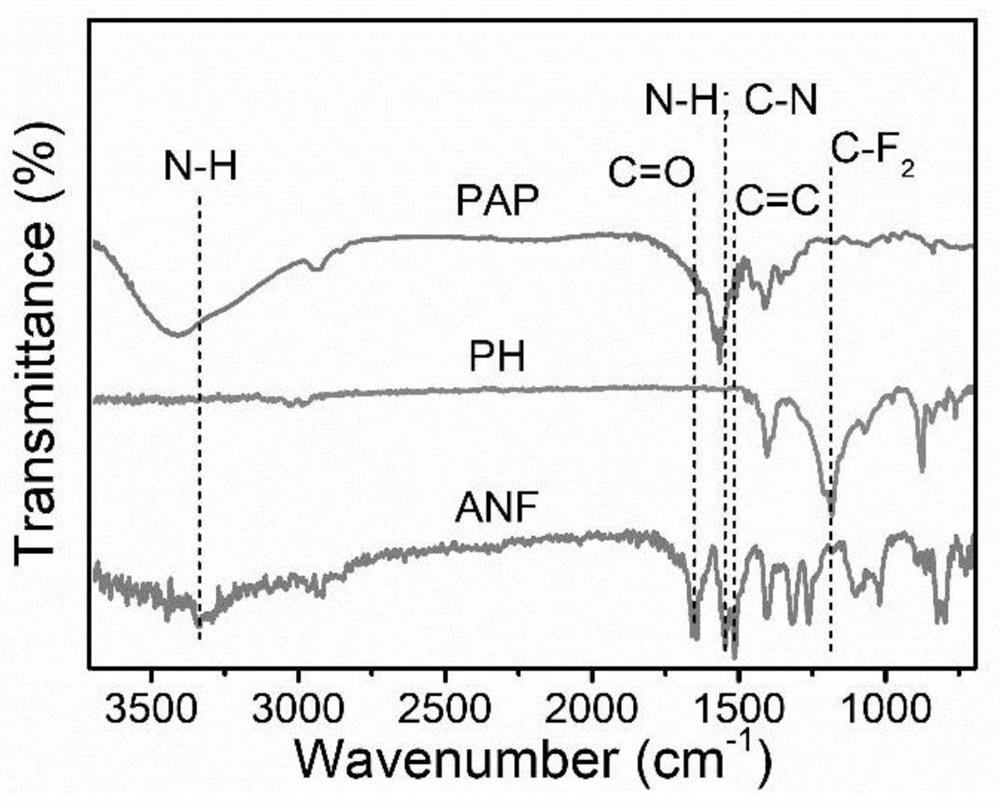

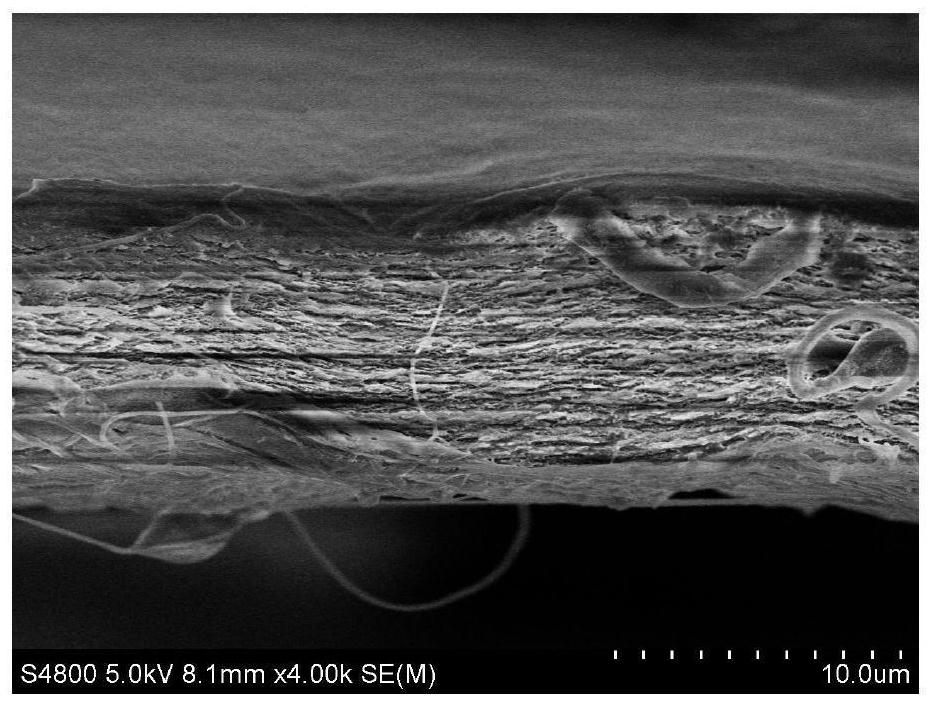

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of the lithium-ion battery composite gel diaphragm described in the above technical solution, comprising the following steps:

[0037] (1) Provide aramid nanofiber casting solution;

[0038] (2) gelling the aramid nanofiber casting solution to obtain the aramid nanofiber hydrogel film;

[0039] (3) drying the aramid nanofiber hydrogel film to obtain an aramid nanofiber diaphragm;

[0040] (4) The polyvinylidene fluoride-hexafluoropropylene solution is electrospun onto both sides of the aramid nanofiber separator, and then dried to obtain a lithium-ion battery composite gel separator.

[0041] In the present invention, unless otherwise specified, each component is a commercially available product well known to those skilled in the art.

Embodiment 1

[0052] Preparation of lithium-ion battery composite gel separator:

[0053] (1) Aramid nanofiber casting solution is provided, and the specific steps include: dispersing aramid fiber and potassium hydroxide with a mass ratio of 1:1 in 100 mL of dimethyl sulfoxide, at a temperature of 30 ° C and a rotation speed of Under the condition of 600r / min, stir for 7 days. During the stirring process, the micron-sized aramid fibers are deprotonated and dissociated into nano-sized aramid fibers to form aramid nanofiber casting solution with a mass fraction of 0.5 wt.%.

[0054] (2) gelling the aramid nanofiber casting solution to obtain the aramid nanofiber hydrogel film, the specific steps include: scraping and coating the aramid nanofiber casting solution with a mass fraction of 0.5wt.% on a glass plate by a scraper superior. Then, soak the glass plate coated with the aramid nanofiber casting solution in deionized water for 12 hours to obtain the aramid nanofiber hydrogel film.

[0...

Embodiment 2

[0058] Preparation of lithium-ion battery composite gel separator:

[0059] (1) Provide aramid nanofiber casting solution, the specific steps include: dispersing aramid fiber and potassium hydroxide with a mass ratio of 1:2 in 150mL of dimethyl sulfoxide, at a temperature of 50°C, stirring speed Under the condition of 700r / min, stir for 10 days. During the stirring process, the micron-scale aramid fibers are deprotonated and dissociated into nano-scale aramid fibers, forming a casting liquid with a mass fraction of 1 wt% aramid nanofibers.

[0060] (2) gelling the aramid nanofiber casting solution to obtain the aramid nanofiber hydrogel film, the specific steps include: scraping and coating the aramid nanofiber casting solution with a mass fraction of 1wt% on a glass plate by a scraper superior. Then, soak the glass plate coated with the aramid nanofiber casting solution in deionized water for 12 hours to obtain the aramid nanofiber hydrogel film.

[0061] (3) drying the ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com